Swinging filtering-separating screen for screening resin

A screening and resin technology, applied in the direction of filtration and separation, moving filter element filters, separation methods, etc., can solve problems such as easy blockage, and achieve the effect of saving water, reasonable structure and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

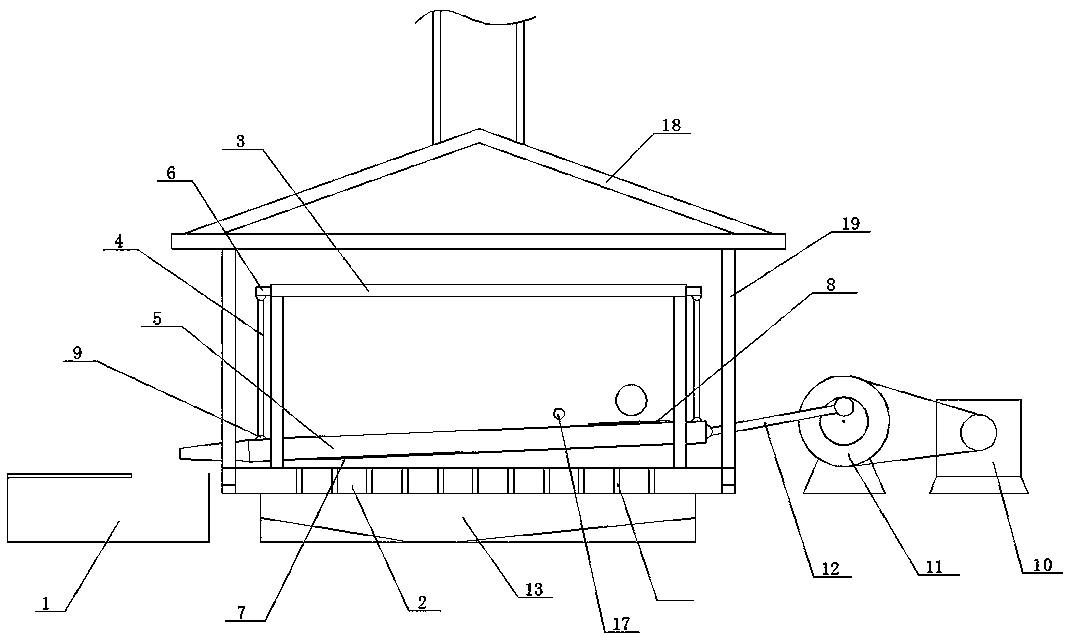

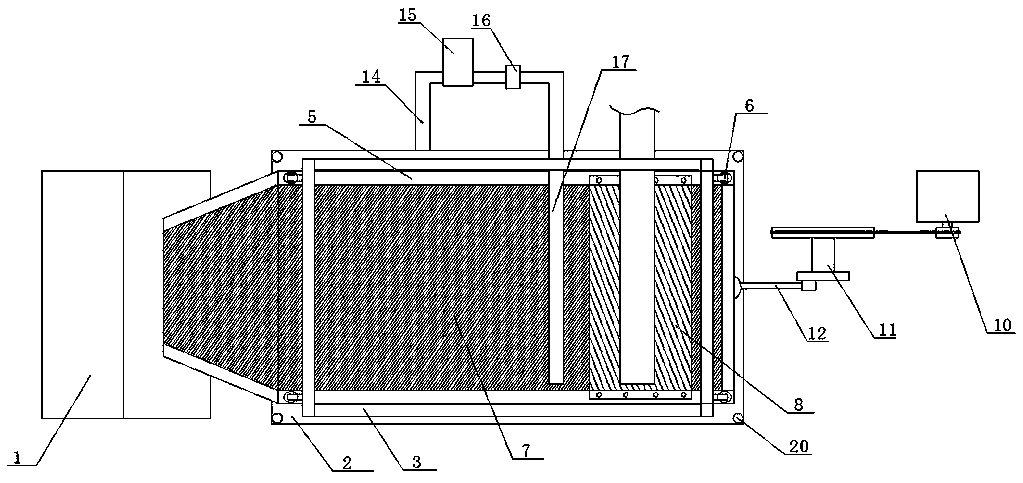

[0016] As shown in the figure, a swing filter screen for filtering resin includes a screening mechanism, a swing mechanism, a circulating water mechanism, an air collecting hood mechanism and a material storage bin 1, and the screening mechanism consists of a base 2, a support frame 3. The suspension rod 4 and the filter screen 5 are composed. The base 2 is a plate structure with several water holes, the support frame 3 is fixed on the upper end of the base 2, and the two sides of the top of the support frame 3 are Both are provided with lifting lugs 6, the suspension rods 4 are provided with four, the upper ends of the suspension rods 4 are hinged with the lifting lugs 6, and the length of two of the four suspension rods 4 is longer than the other two. The sieve 5 is a rectan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com