High-pressure water jet vacuum environment-friendly glazing device

A high-pressure water jet and vacuum technology, applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve problems such as dispersion in the working environment, impact on workers' health, and polluted water sources. It is easy to manufacture, simple in structure, and The effect of little environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

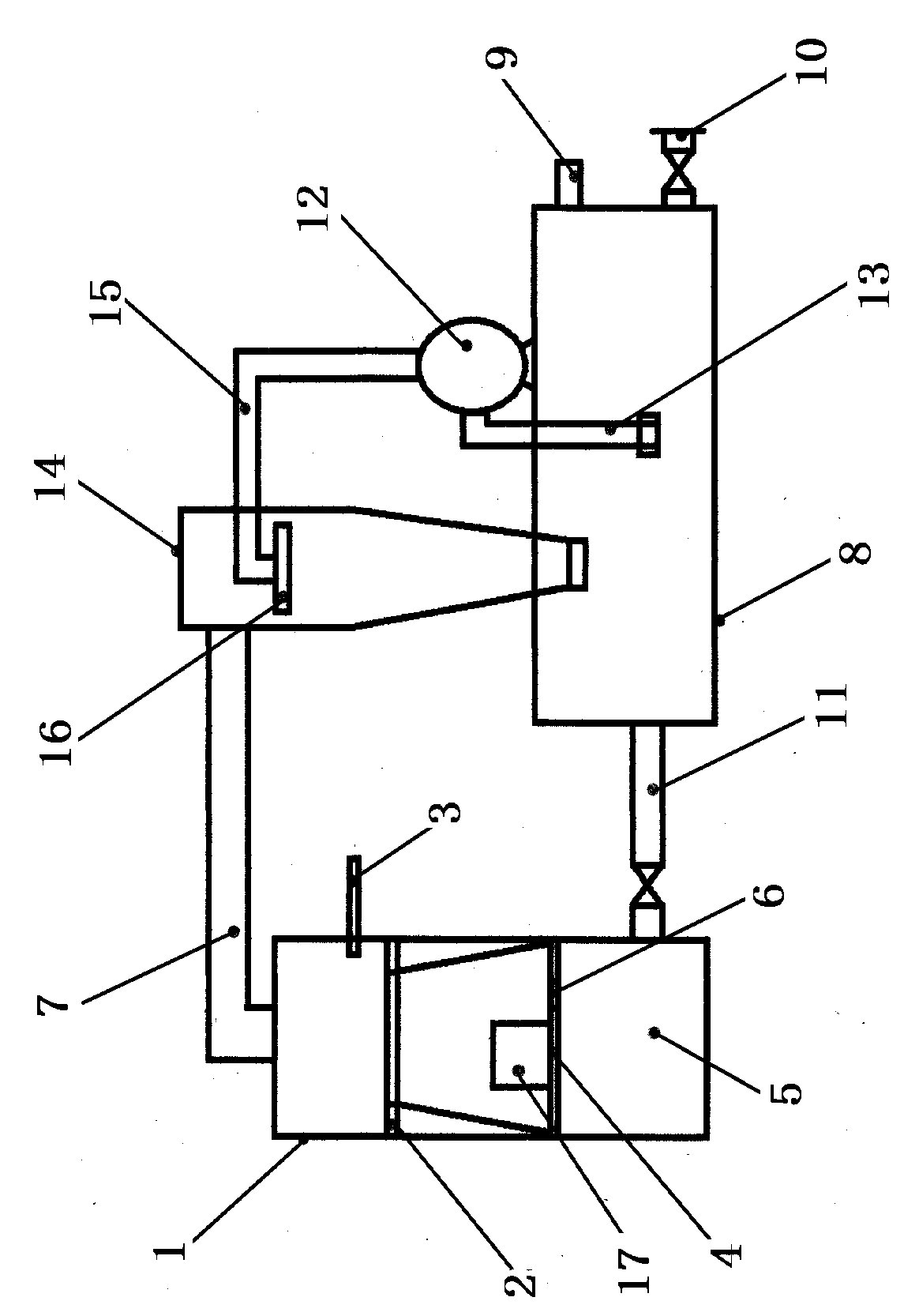

[0010] Combine below figure 1 The present invention is further described;

[0011] It includes a glazing cabinet 1, the glazing cabinet includes a back board, two side boards, a bottom board and a top board, the rear ends of the two side boards are connected and fixed with the back board, the upper ends of the two side boards and the back board are connected and fixed with the top board, The lower ends of the side panels and the back panel are connected and fixed to the bottom panel, and upper water storage tanks 2 are arranged on the two side panels and the back panel in the glazing cabinet. The upper water storage tanks on the two side panels and the back panel are connected, and the water inlet pipe 3 Extend into the glazing cabinet from the side plate above the upper water storage tank, the water outlet of the water inlet pipe is located directly above the upper water storage tank, the lower part of the glazing cabinet is provided with a partition 4, and the lower water st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com