Catalytic device for high-power distributed energy tail gas purification DeNOx system

A technology for distributed energy and exhaust gas purification, which is applied in the direction of exhaust devices, noise reduction devices, engine components, etc., and can solve the problems of scattered distributed energy layout, difficulty in centralized treatment of exhaust gas, complex system structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with specific embodiments.

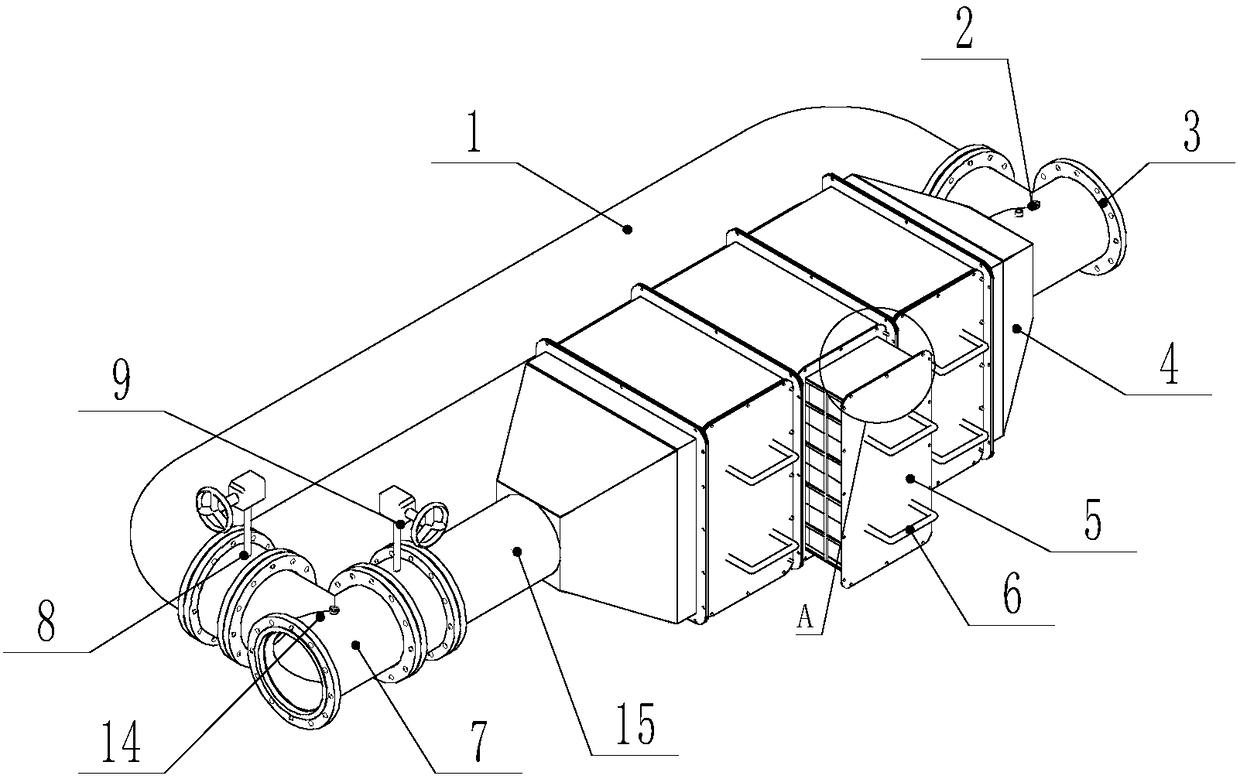

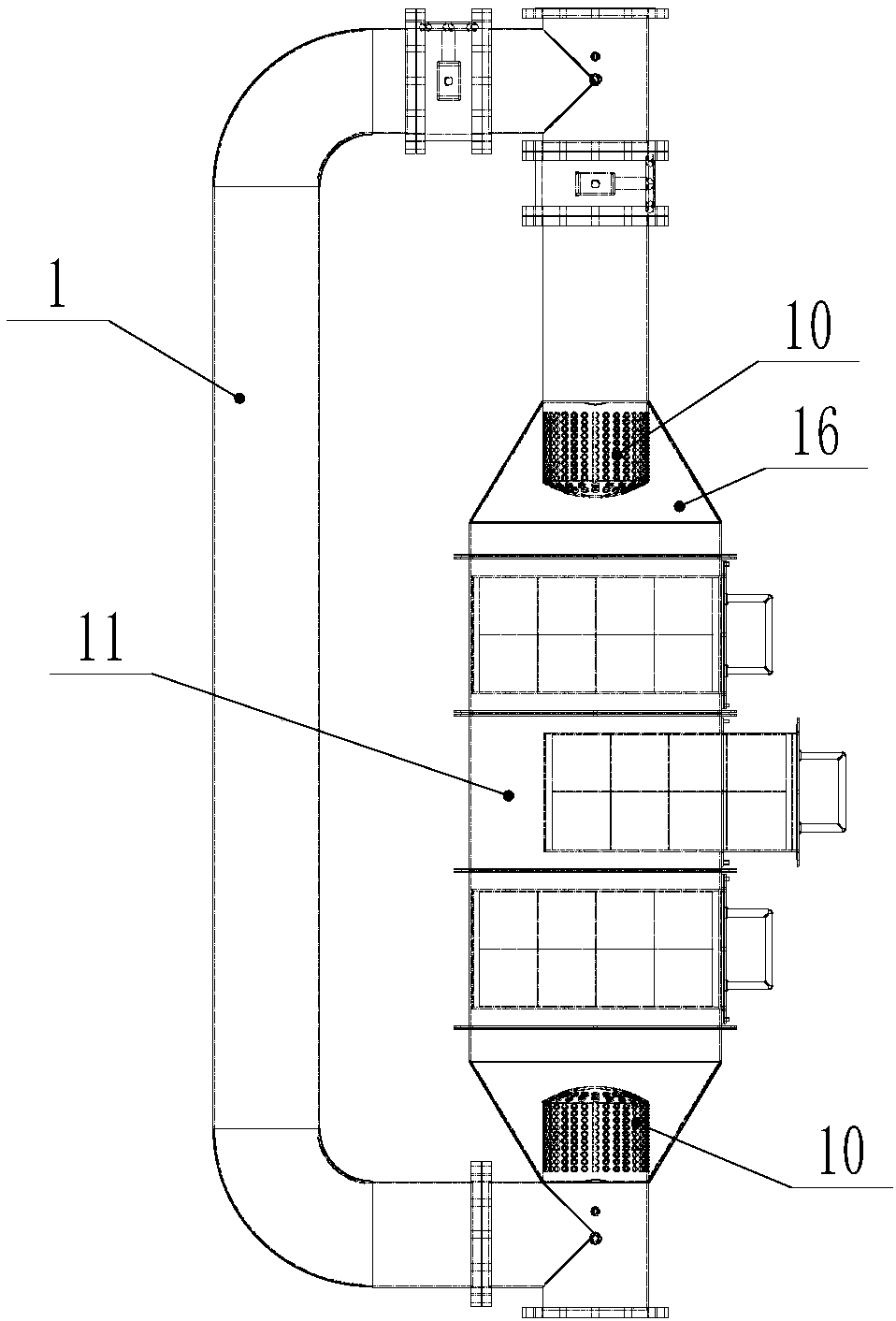

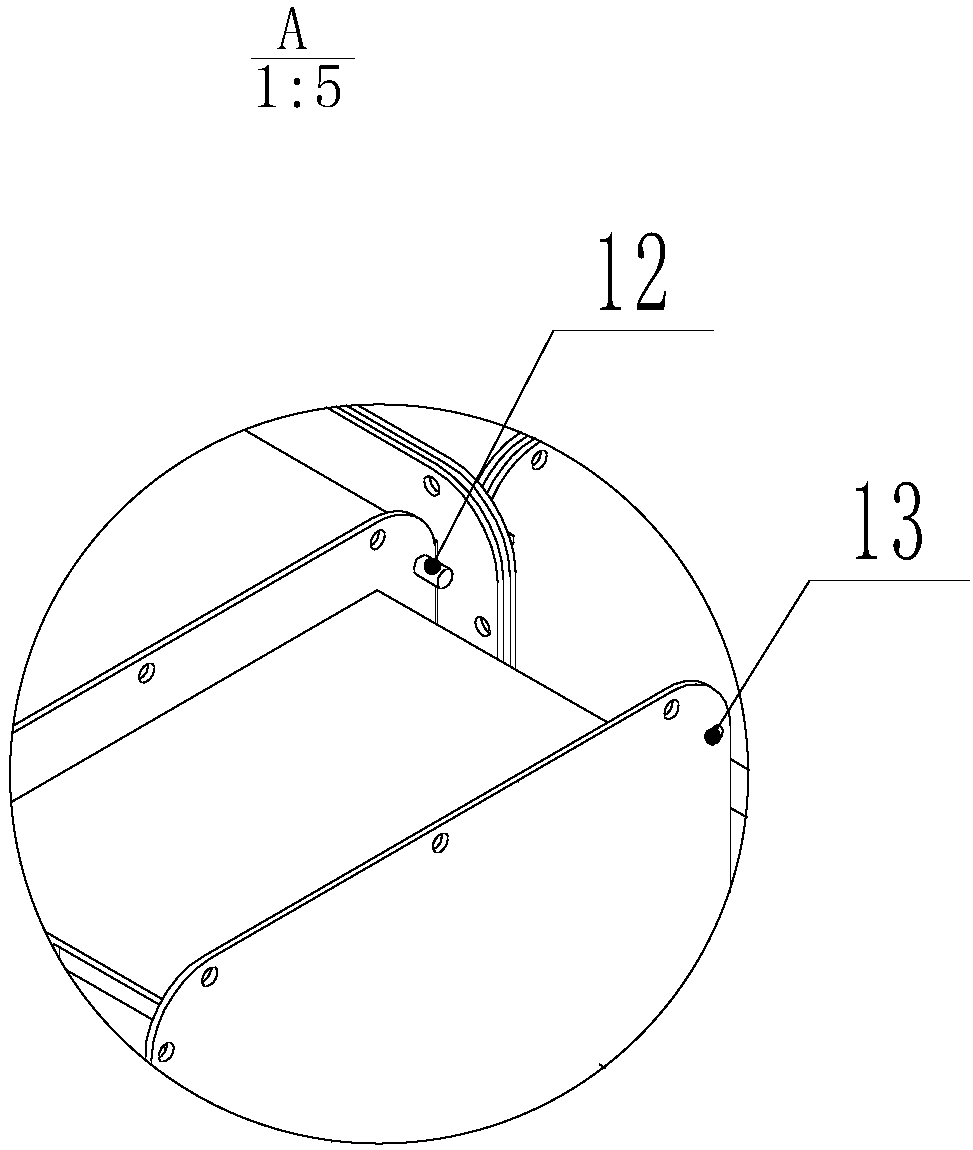

[0021] Such as Figure 1 to Figure 3 The catalytic device for a high-power distributed energy exhaust purification DeNOx system shown includes a detachable catalytic module 5, an air inlet joint 7, an air outlet joint 3, a muffler 10, a sensor seat 2, a urea nozzle mounting seat 14, a main Through butterfly valve 9, bypass butterfly valve 8, catalytic module installation box 4 and maintenance bypass pipe 1; inlet joint 7 and outlet joint 3 are three-way connection pipe joints, and each outlet end has its own connecting flange, which is convenient Install.

[0022] Both the main passage butterfly valve 9 and the bypass butterfly valve 8 are D373H / D673H / D973H triple eccentric wafer butterfly valves or D643H triple eccentric flange butterfly valves.

[0023] The maintenance bypass pipe 1 is U-shaped, and its two ends are provided with connecting flanges.

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com