Optical fiber point type temperature vibration sensing device and system

A vibration sensing, optical fiber sensing technology, applied in thermometers, measuring devices, thermometers with physical/chemical changes, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

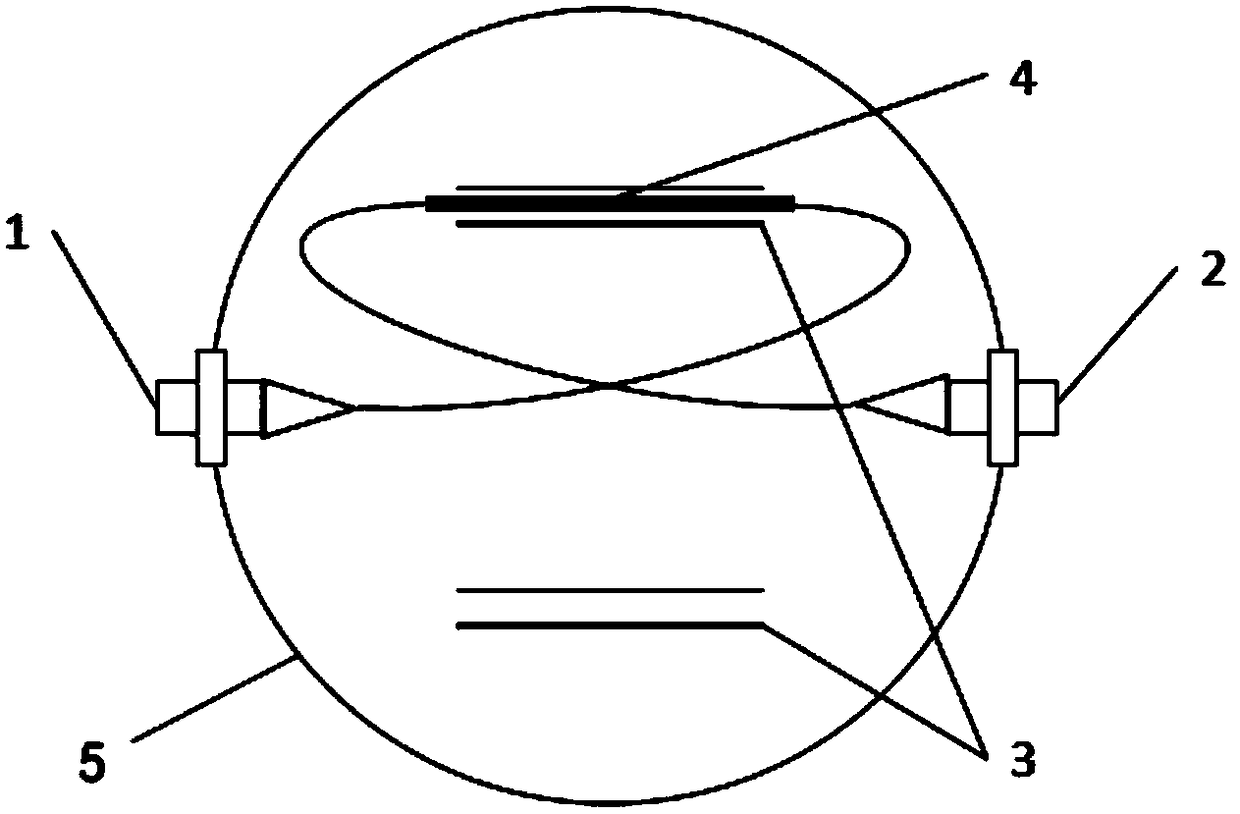

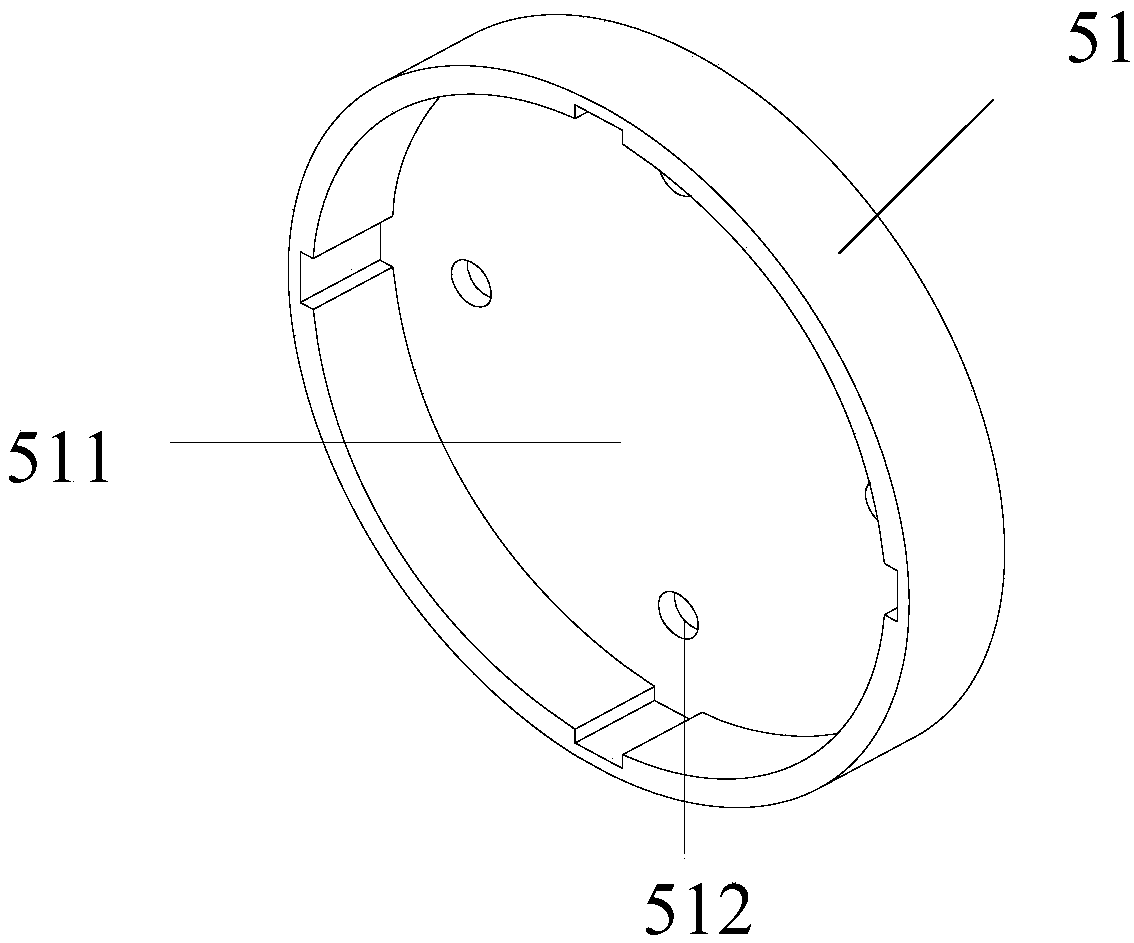

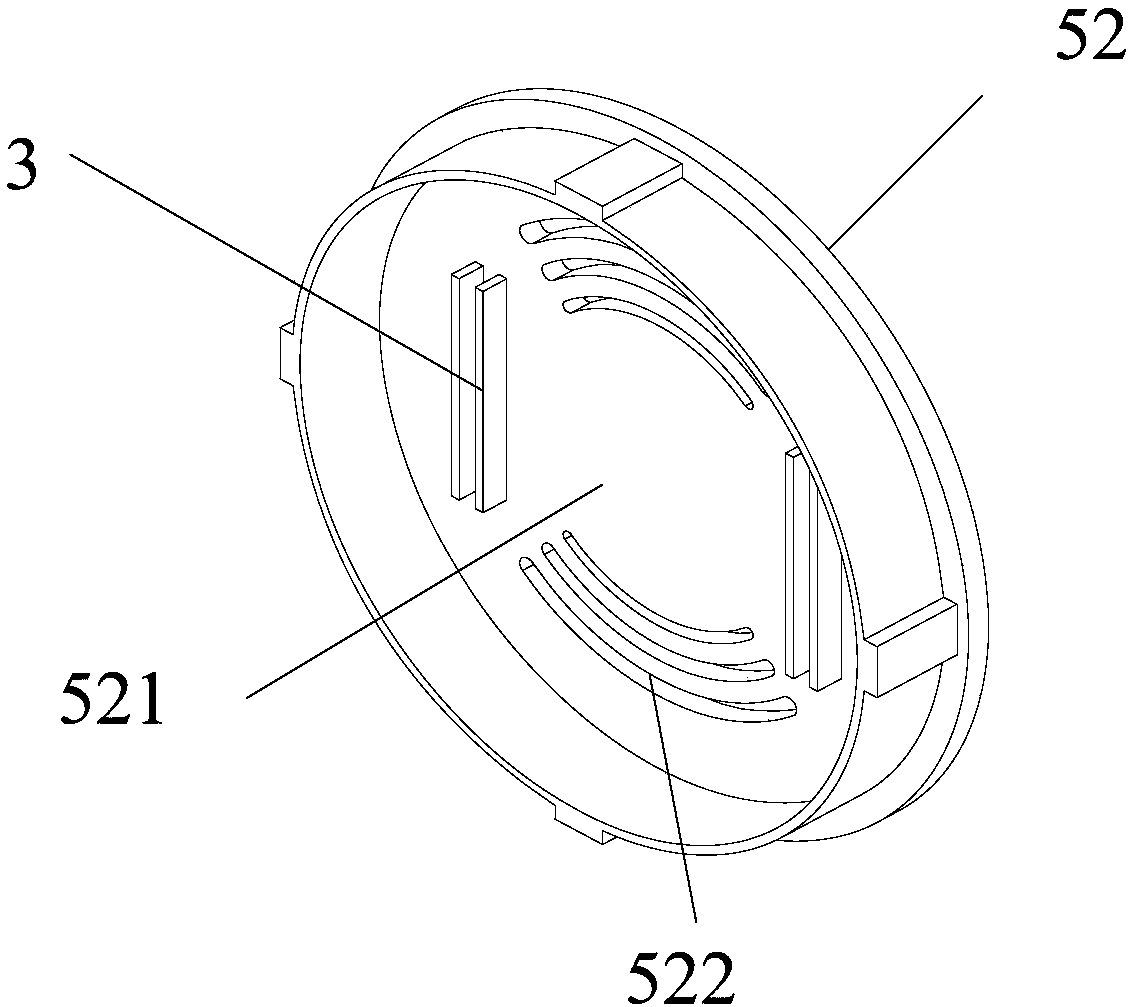

[0033] like figure 1 As shown, the embodiment of the present invention provides a fiber optic point temperature vibration sensing device, including: a housing 5, an incident flange 1, an exit flange 2, a fixing buckle 3 and a sensing element 4, the incident flange and The outgoing flange is arranged on the housing, the fixing buckle is arranged in the housing, the sensing element is fixedly mounted on the fixing buckle, the incident flange, the sensing element and the outgoing The flanges are connected in series by measuring optical fibers.

[0034] In actual use, the incident light enters the device from the incident flange, and exits from the exit flange through the sensing element. The incident light here refers to the sensing incident light; when only one measurement point needs to be measured, that is, when there is only one optical fiber point temperature vibration sensing device, the sensing incident light can be the light emitted by the light source; When there are t...

Embodiment 2

[0075] like Figure 4 As shown, the embodiment of the present invention provides a fiber optic point temperature vibration sensing system, including: fiber optic sensing equipment 100 and the fiber optic point temperature vibration sensing device 200 as mentioned in the previous embodiment, the fiber optic sensor The equipment is connected with the optical fiber point type temperature vibration sensing device.

[0076] Specifically, the optical fiber sensing device is connected to the optical fiber point temperature vibration sensing device through an optical fiber. The fiber here is the same fiber type and type as the measurement fiber.

[0077] Further, there are one or more optical fiber point temperature vibration sensing devices. The optical fiber point temperature vibration sensing device can be determined according to the number of points to be measured and the type of optical fiber of the sensing element.

[0078]Specifically, when the sensing element is an ordinary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com