Fault diagnosis method based on shafting rotation speed large fluctuation of automatic encoder

An autoencoder and fault diagnosis technology, which is applied in the testing of machines/structural components, instruments, mechanical bearings, etc., can solve problems that affect the final fault diagnosis effect and accuracy, model repetition training, etc., and achieve high accuracy, Improve accuracy and robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

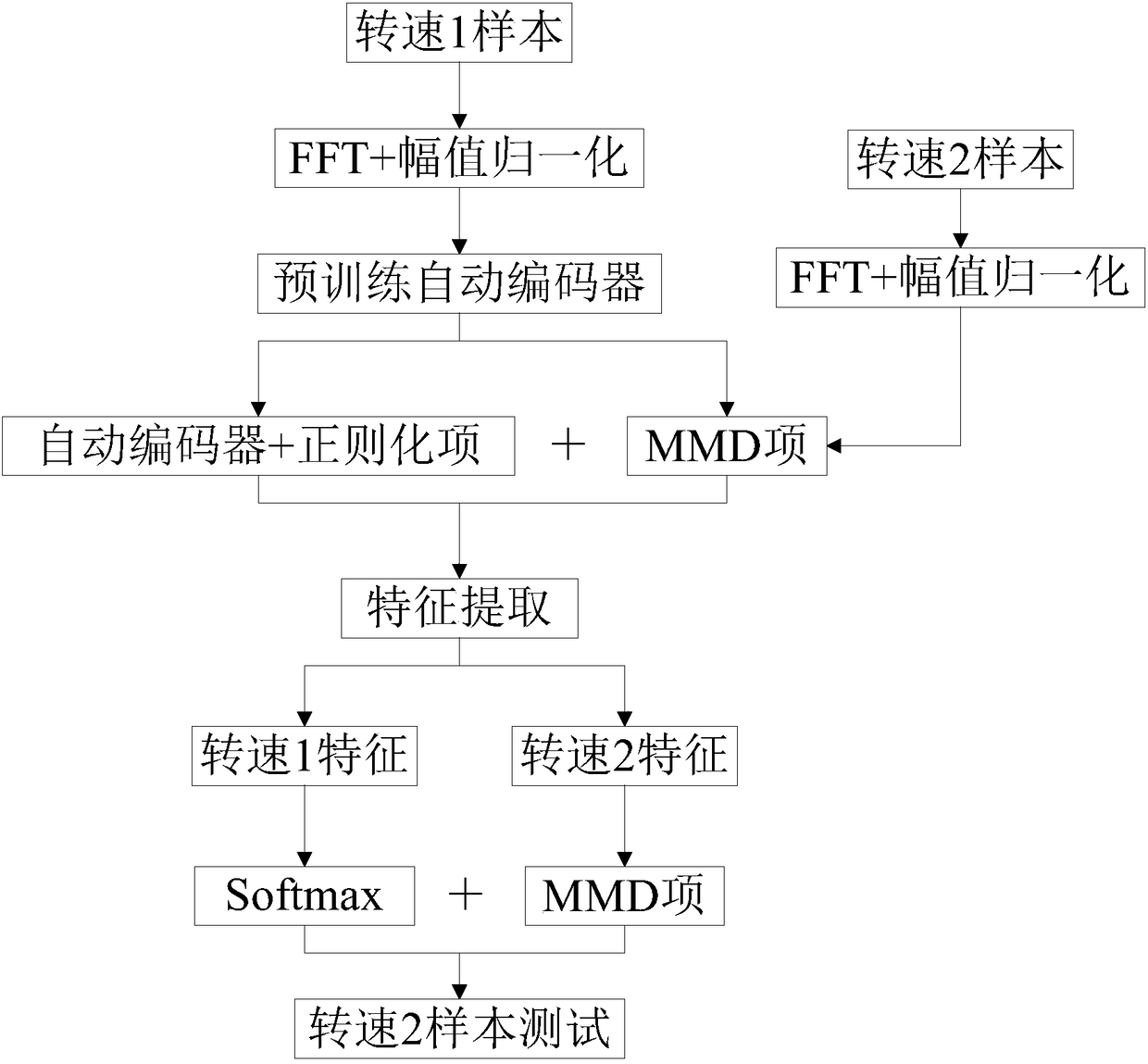

[0020] A method for diagnosing faults based on an automatic encoder for large fluctuations in the shafting speed of the present invention comprises the following steps:

[0021] Step 1. Sample data preprocessing: perform fast Fourier transform on the samples of speed 1 and speed 2 and normalize the amplitude;

[0022] Step 2. Pre-train the autoencoder: pre-train the autoencoder with the rev 1 signal;

[0023] Step 3. Train the transfer learning model based on the autoencoder: add the MMD penalty item to the autoencoder algorithm to automatically encode the transfer learning algorithm, and use the training samples of two rotation speeds for training;

[0024] Step 4. Train the Softmax-based migration learning classifier: Train the Softmax feature classifier with the MMD penalty item to classify the extracted features, so that fault diagnosis can be realized for the fault signal with unknown speed 2.

[0025] The present invention will be described in further detail below in co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com