Method for determining volatile components of tobacco blasting bead by solid phase microextraction-gas chromatography-mass spectrometry

A volatile component, solid-phase micro-extraction head technology, applied in the field of tobacco, to achieve good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1 Samples, standards and instruments

[0030] 1.1 Instruments and equipment

[0031] GC-MS Gas Chromatography-Mass Spectrometry Instrument US PE Company; Supelco Solid Phase Microextraction Device US Supelco Company; Extraction head is 65 μm PDMS / DVB extraction head US Supelco Company.

[0032] 1.2 Sample

[0033] Randomly select cigarette products containing explosive beads from China Tobacco Industry Co., Ltd. in Shaanxi Province.

[0034] 2. Adsorption and desorption of aroma substances

[0035] Put the solid-phase micro-extraction head in the gas chromatograph inlet and age it at 250°C for 30 minutes for standby; randomly select 20 cigarettes, take out the cigarette popping beads and put them into the solid-phase micro-extraction bottle, quickly break the popping beads and seal them with the lid . Put it in a constant temperature water bath at 80°C for 30 minutes to fully volatilize and balance the aroma; then insert the needle of the solid phase microextraction...

Embodiment 2

[0047] 1. Comparison of different extraction methods

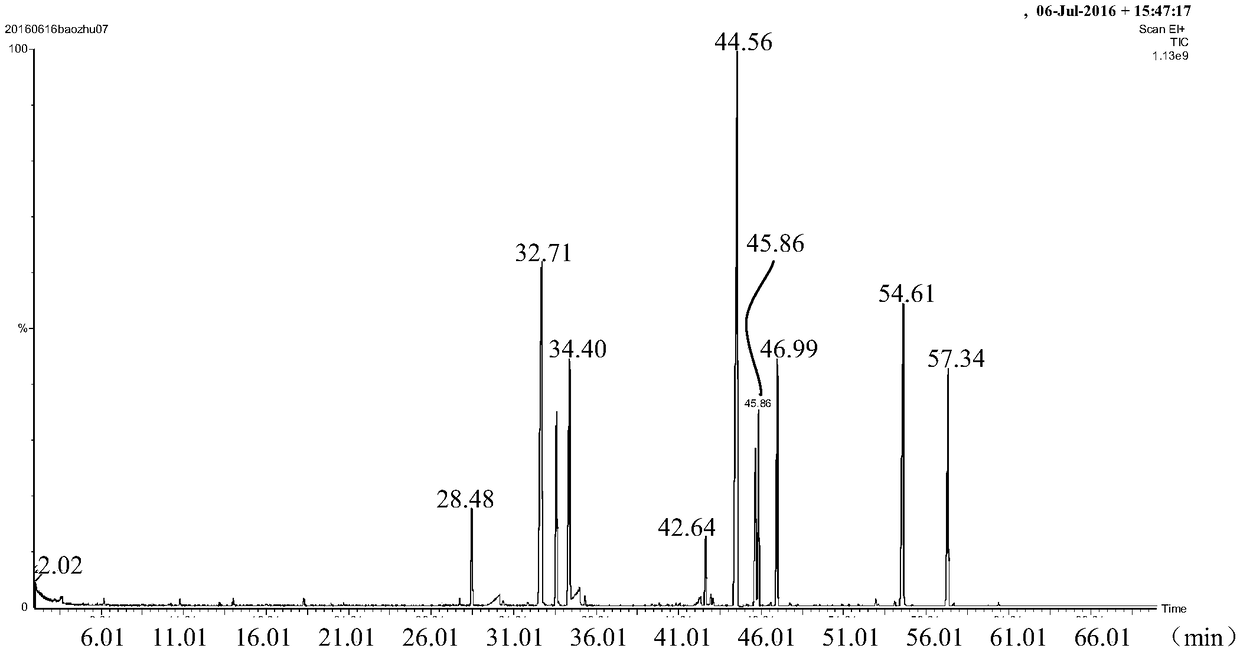

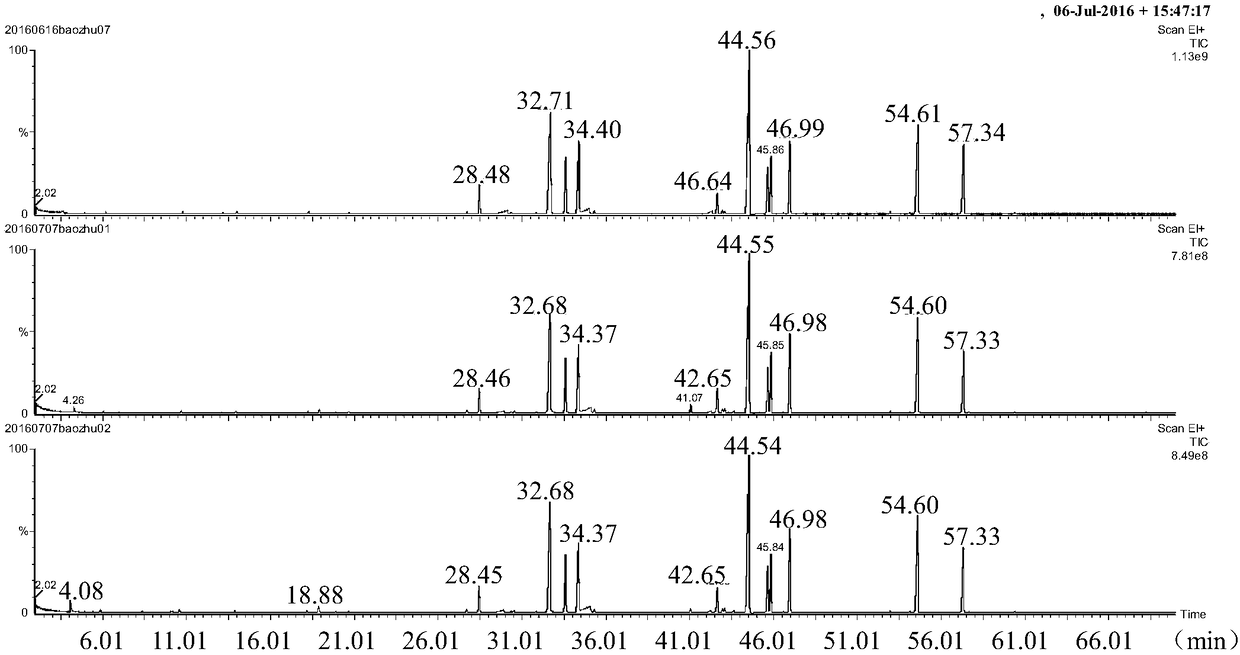

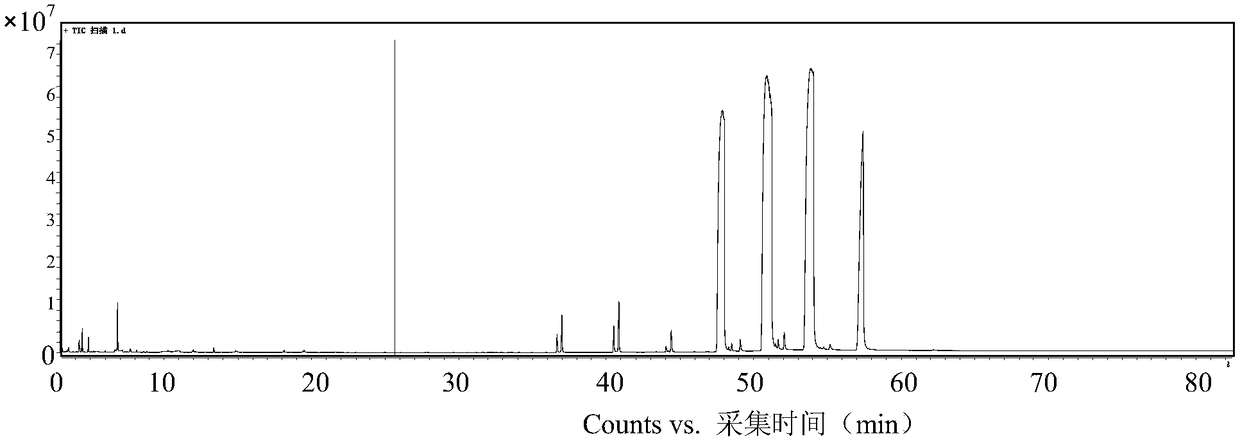

[0048] Method 1: Randomly select 20 pop-up beads, break the pop-up beads, add 20mL dichloromethane for ultrasonic extraction for 30min, take out the sample and let it stand for 30min, filter it through a 0.45μm organic phase needle filter membrane, and then perform GC-MS detection; the spectrum of the sample is as follows: image 3 and shown in Table 2.

[0049] Table 2 Dichloromethane Ultrasonic Extraction Component Analysis Table

[0050] serial number

keep time

name

CAS number

molecular formula

1

4.56

Dihydrofuran

1191-99-7

C 4 h 6 o

2

6.86

L-menthol

2216-51-5

C10H20O

3

36.67

Glyceryl Tricaprylate

538-23-8

C27H50O6

4

37.009

Glyceryl Tricaprylate Isomers

538-23-8

C27H50O6

5

44.42

Glyceryl tricaprate

621-71-6

C33H62O6

6

48.02

Glyceryl Tricaprylate Isomers

538-23-8

C27H50O6

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com