Finite-time neural network control method of motor-driven single-connection rod manipulator

A technology of neural network control and motor drive, which is applied in the direction of adaptive control, general control system, control/regulation system, etc., and can solve problems such as system uncertainty, dead zone input, output limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0268] Example: Motor-driven single-link manipulator

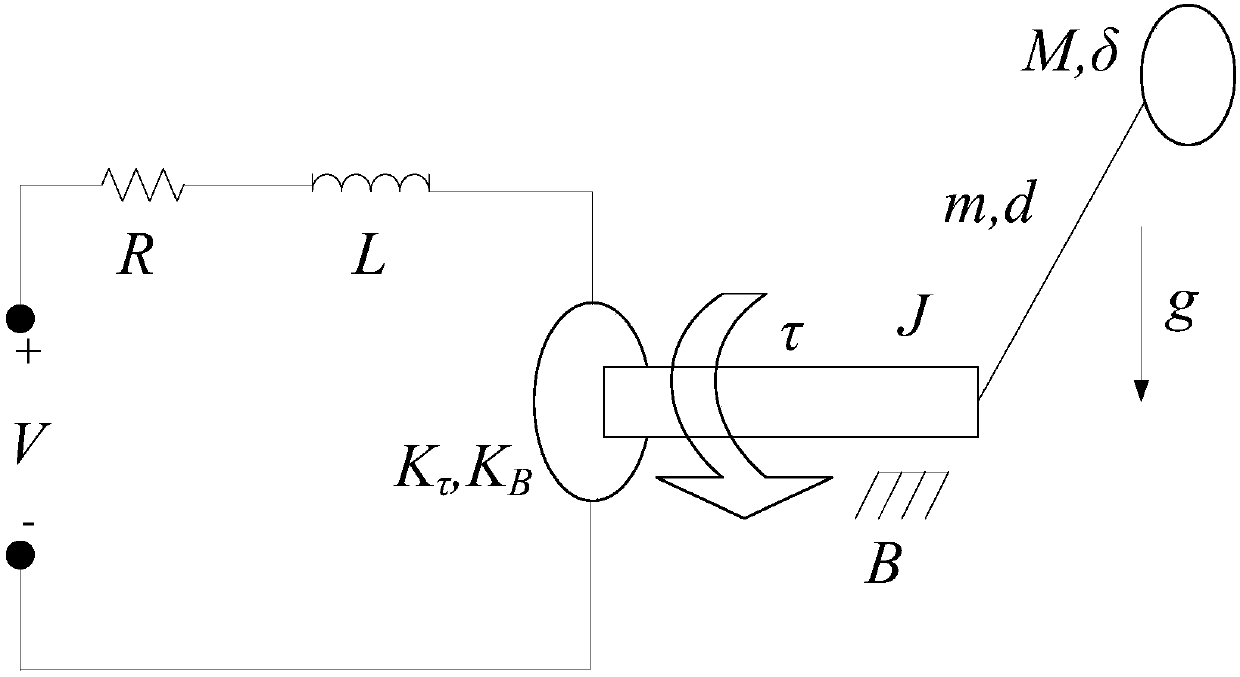

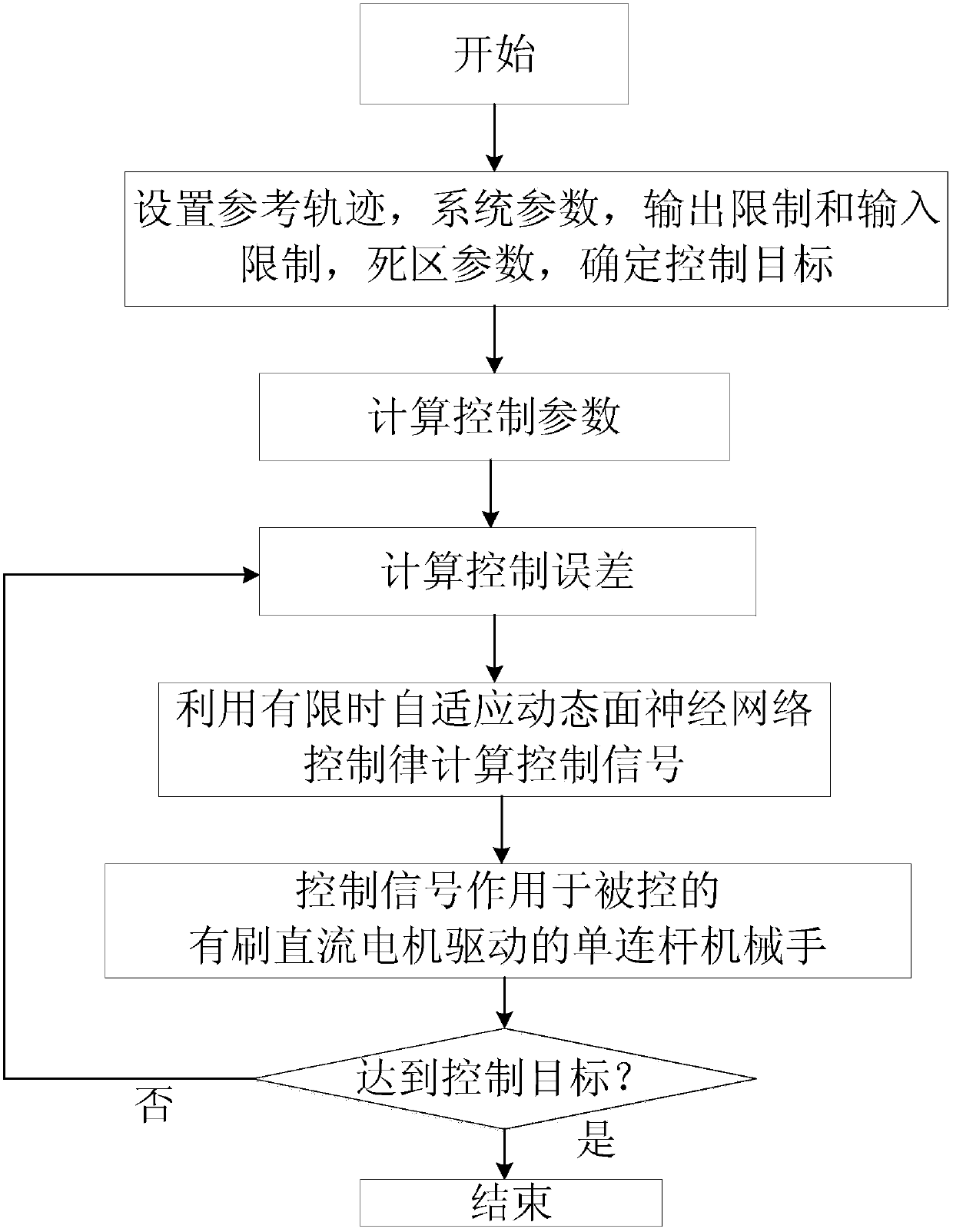

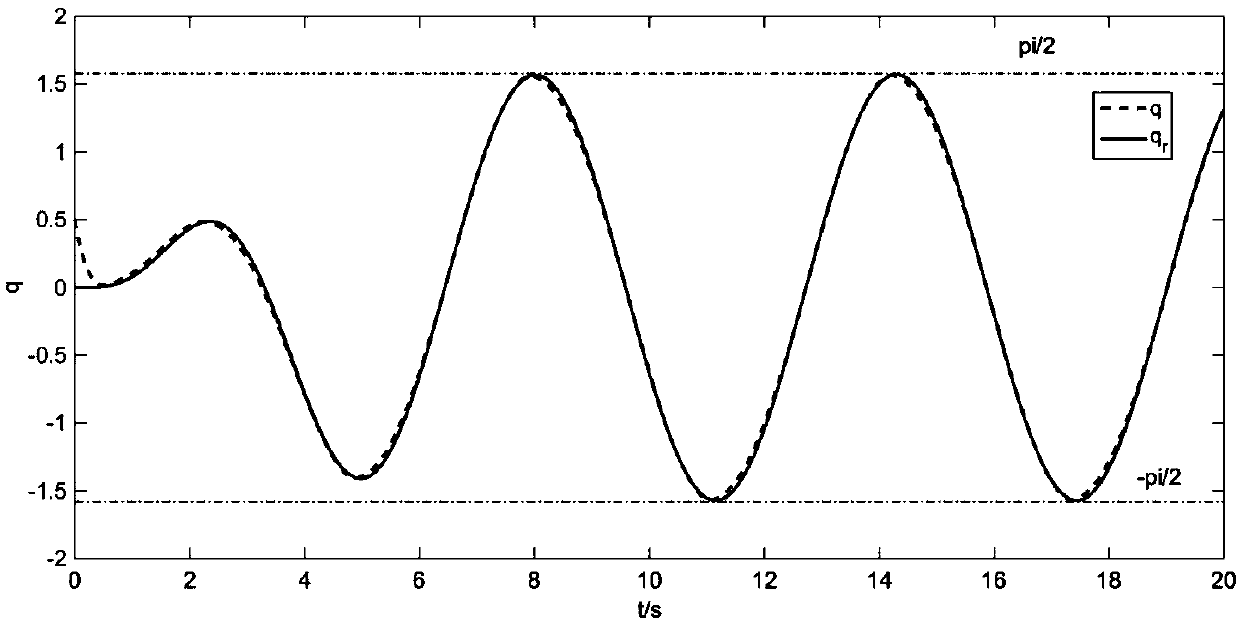

[0269] Taking the motor-driven single-link manipulator as an example to illustrate the effectiveness of the above-mentioned finite-time neural network control method in realizing the ideal trajectory tracking of the driven single-link manipulator. Such as figure 1 As shown, the system consists of a motor and a single-link manipulator. The dynamic equation of the system is as follows:

[0270]

[0271] In the formula, q, Respectively represent the angular position, angular velocity and angular acceleration, I is the motor armature current, ΔI is the current interference, L is the armature inductance, R is the armature resistance, K B is the counter electromotive force coefficient, V is the input control voltage, y is the system output, limited to the open set Ω={y:|y|c},k c is a normal constant representing the limit boundary, with The expression of is as follows:

[0272]

[0273]

[0274]

[0275] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com