High-power lithium ion battery thermal management system

A lithium-ion battery and thermal management system technology, which is applied in the field of high-power lithium-ion battery thermal management systems, can solve problems such as unsuitable sports scenes, and achieve the effects of simplifying the automatic control process, improving safety and reliability, and efficient heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0045] The lithium battery module 1 is composed of 48 218*140*6mm monomers with a 2P24S structure, the surface of 140*6mm is parallel to the lower bottom plate, and the sideways arrangement of the monomers leaves the flow channels for liquid and gas.

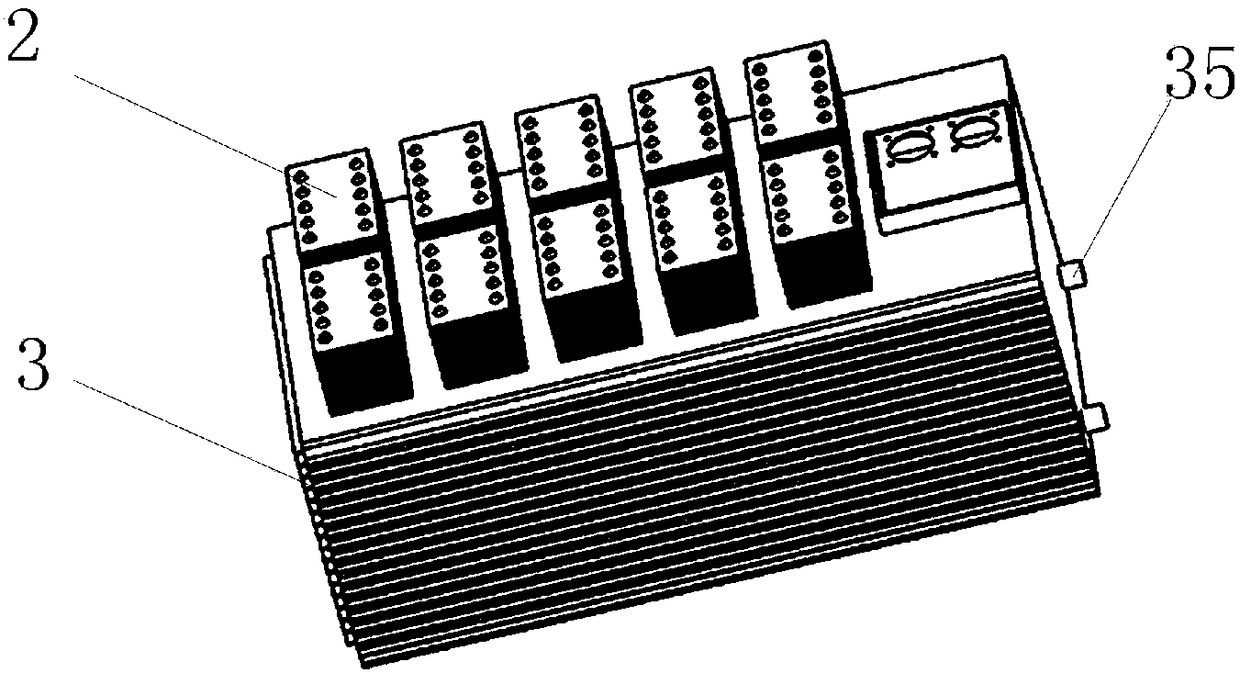

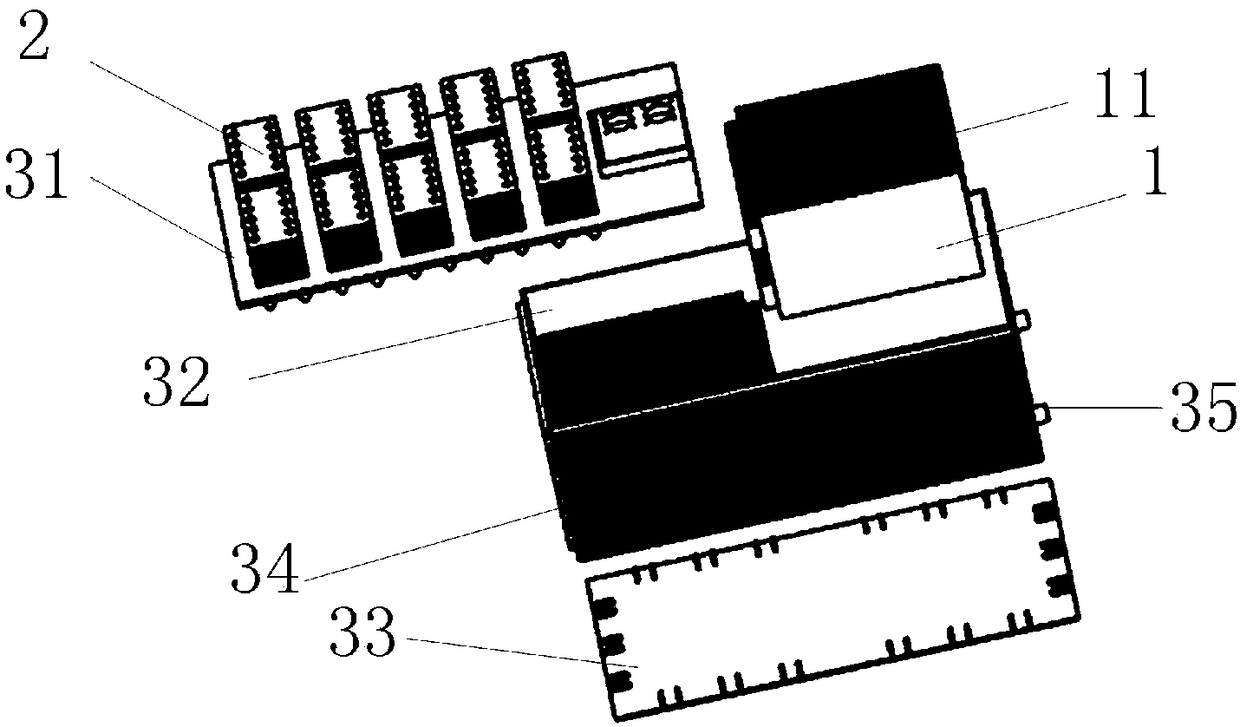

[0046] Such as figure 2 As shown, the energy storage box 3 includes an upper cover plate 31, a bottom plate 33, a side panel 32 and a sealing strip 39; the side panels 32, the upper cover plate 31 and the bottom plate 33 of the energy storage box 3 A groove 38 is provided at the overlap of the grooves, and a sealing strip 39 is placed in the groove 38, and the grooves 38 on two adjacent surfaces wrap the sealing strip 39 to form a sealed connection structure, such as Figure 8 shown.

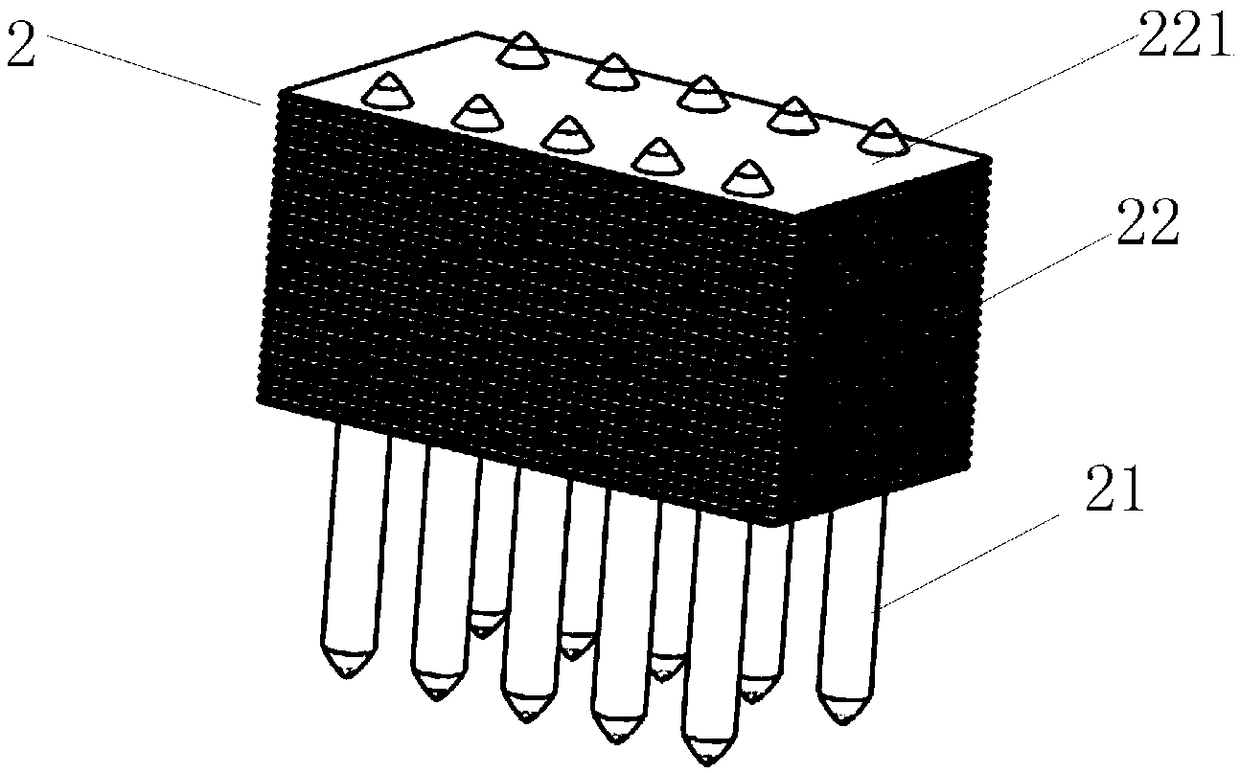

[0047] The components that realize the heat dissipation function include a phase-change cooling liquid 4 and a heat pipe radiator unit 2, and a plurality of the heat pipe radiator units 2 are arranged at certain intervals to form a condensation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com