Processing method of fresh glycol type summer and autumn green tea in Jiangbei tea region

A processing method and technology of fresh glycol, applied in the field of high-quality green tea processing, can solve the problems of uneven shape and size of strands, not fully exerted, and deep yellow and green soup color, and achieve the effects of avoiding dark and dark color, reducing breakage rate and reducing bitterness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

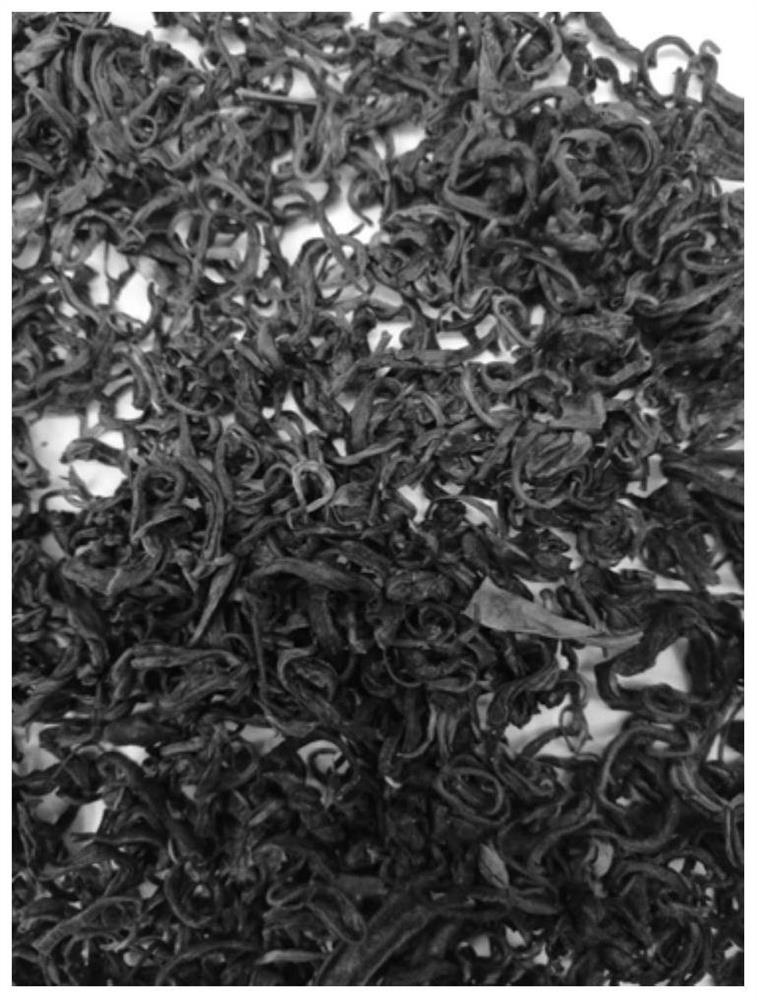

Image

Examples

Embodiment Construction

[0032] The raw materials of summer and autumn tea leaves in the Jiangbei tea area are characterized by: (1) long internodes; (2) large difference in size between the second leaf and the first leaf.

[0033] A method for processing fresh glycol type summer and autumn green tea from Jiangbei tea area, the steps are as follows:

[0034] 1. Standards for fresh leaves: picking new shoots or a single young leaf (second leaf) with 1 bud and 1 leaf in summer and autumn, and picking diseased and insect leaves, rain leaves, and dew leaves are prohibited; fresh leaves are packed in ventilated baskets and transported to the processing plant , during which to avoid mechanical damage and heap boredom.

[0035] 2. Long stand and short vibration: put the fresh leaves in air-drying / withering equipment (such as existing silage machine, lift-type drying / withering equipment) or utensils (such as: existing bamboo trays for spreading tea leaves) , the thickness of the spreading leaves is based on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com