Time difference type centrifugal solid liquid separator

A technology of solid-liquid separator and time difference, which is applied in the direction of separation method, dispersed particle separation, chemical instrument and method, etc., can solve the problems of poor purification effect, troublesome installation, high cost, etc., and achieve saving of later maintenance investment and convenient production and processing , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

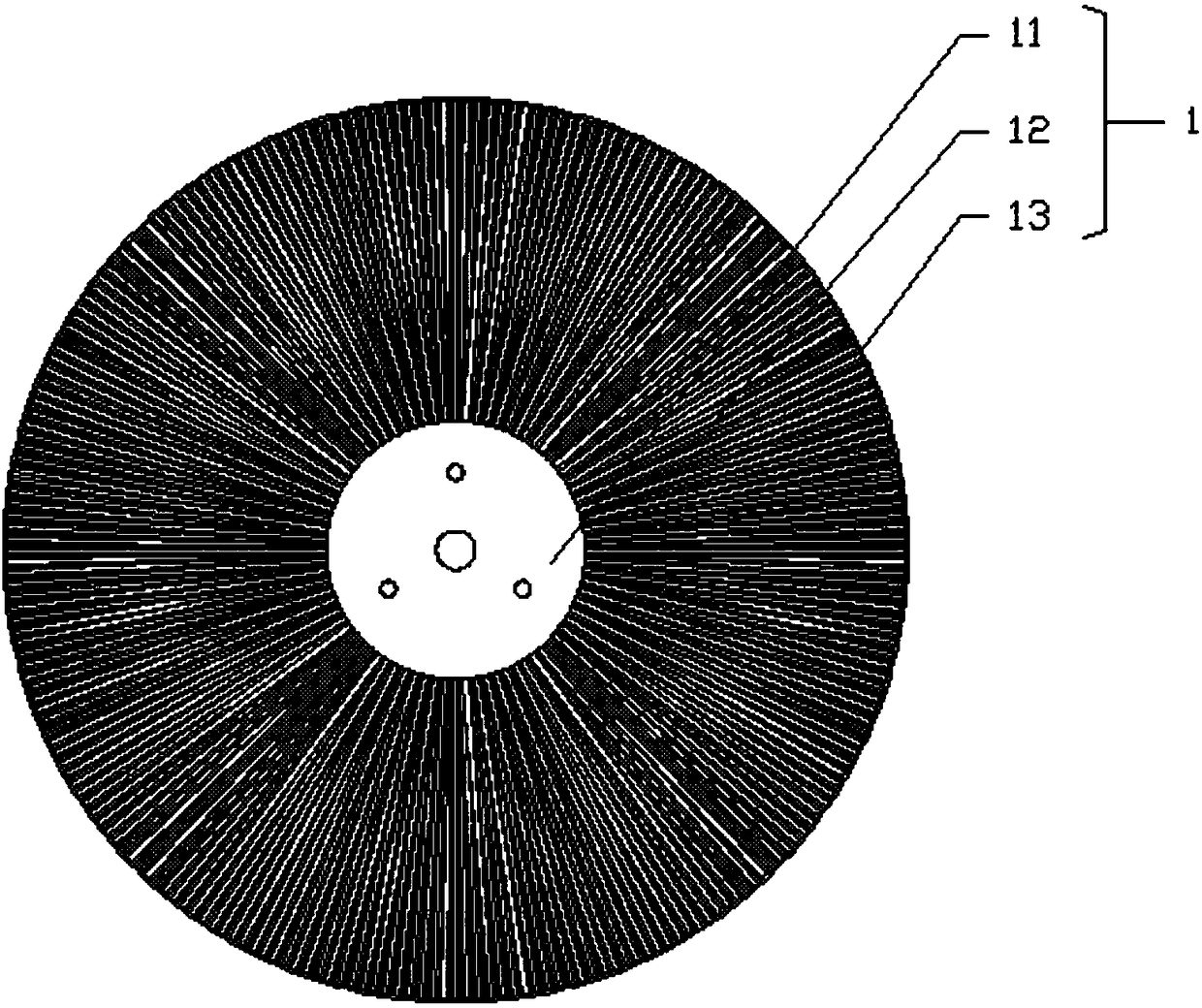

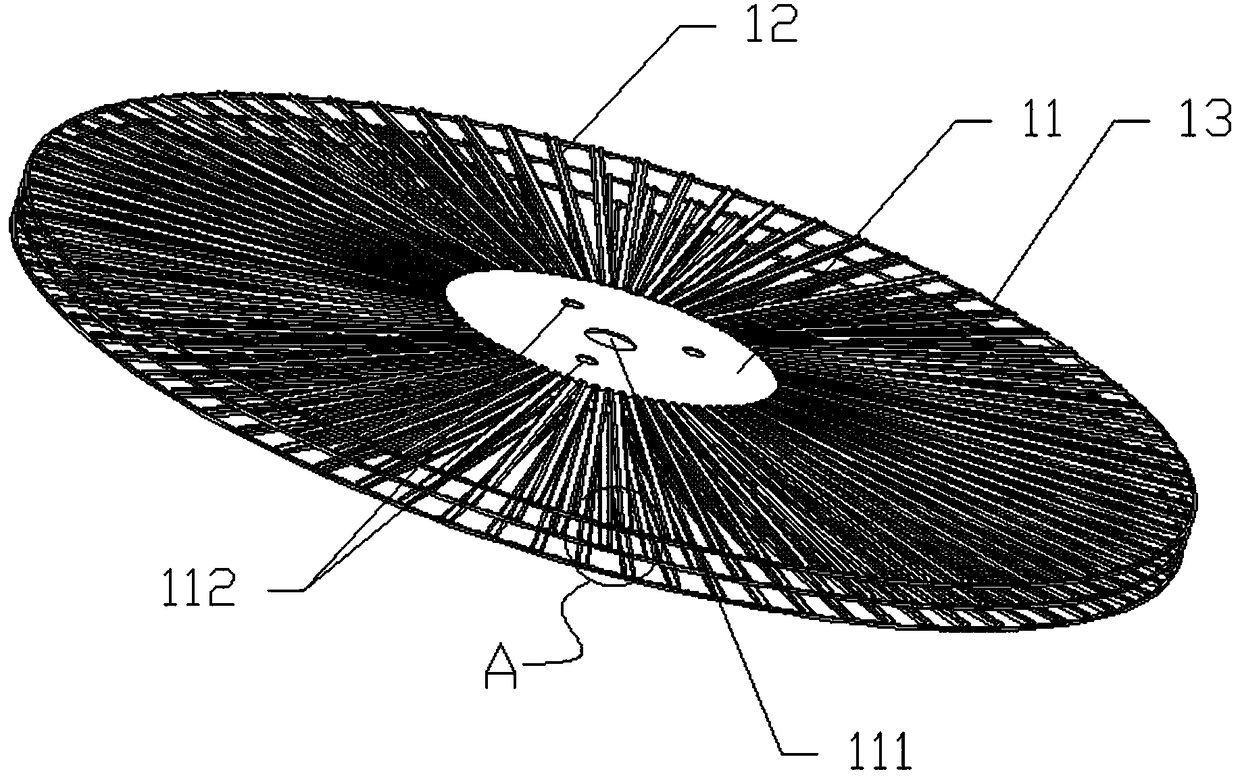

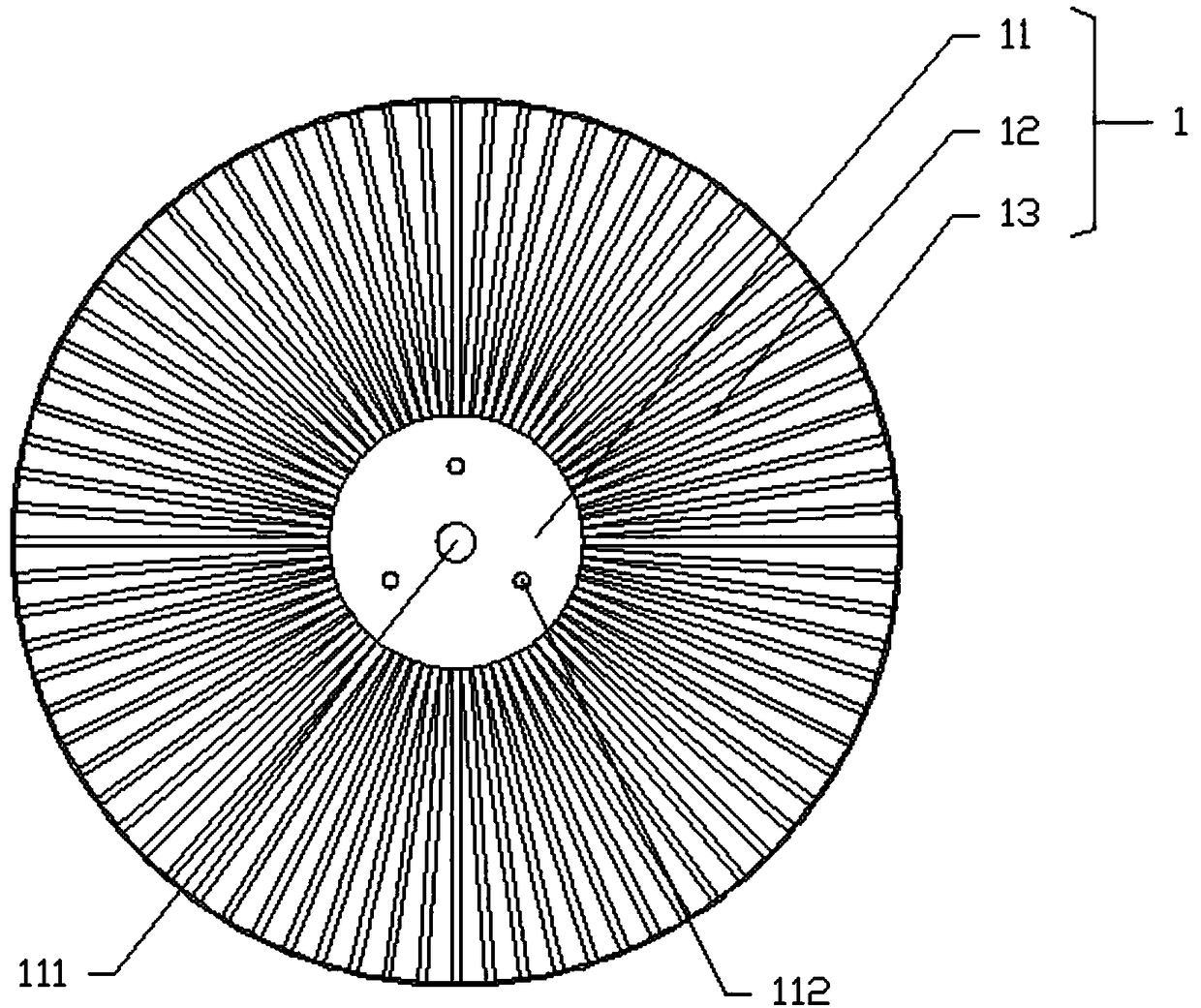

[0033] Such as Figure 1-7 As shown, the present invention proposes a time-difference centrifugal solid-liquid separator, which includes a plurality of coaxially stacked radial blade disks 1. Specifically, the blade disk 1 includes a circular mounting disk 11, which is fixed on the mounting disk 11. The outer edge of the blade 12 and the fixed ring 13 arranged around the outer edge of the blade 12, that is, the fixed ring 13 is coaxially sleeved outside the mounting disk 11, and the blade 12 is connected between the fixed ring 13 and the mounting disk 11, wherein each blade 12 is arranged along the radial direction of the mounting disk 11, and all the blades 12 are equally spaced along the circumferential direction of the mounting disk 11 to form a uniform radial structure.

[0034] The center of the mounting plate 11 is provided with a mounting hole 111, and the outer side of the mounting hole 111 is also provided with a number of auxiliary mounting holes 112 distributed at equa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com