Method of preparing annular part from Ti2AlNb alloy and TiAl powder

A powder preparation and alloy powder technology, which is applied in the field of static pressure diffusion connection to prepare ring parts, to achieve the effects of expanding the scope of engineering applications, reliable connection, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

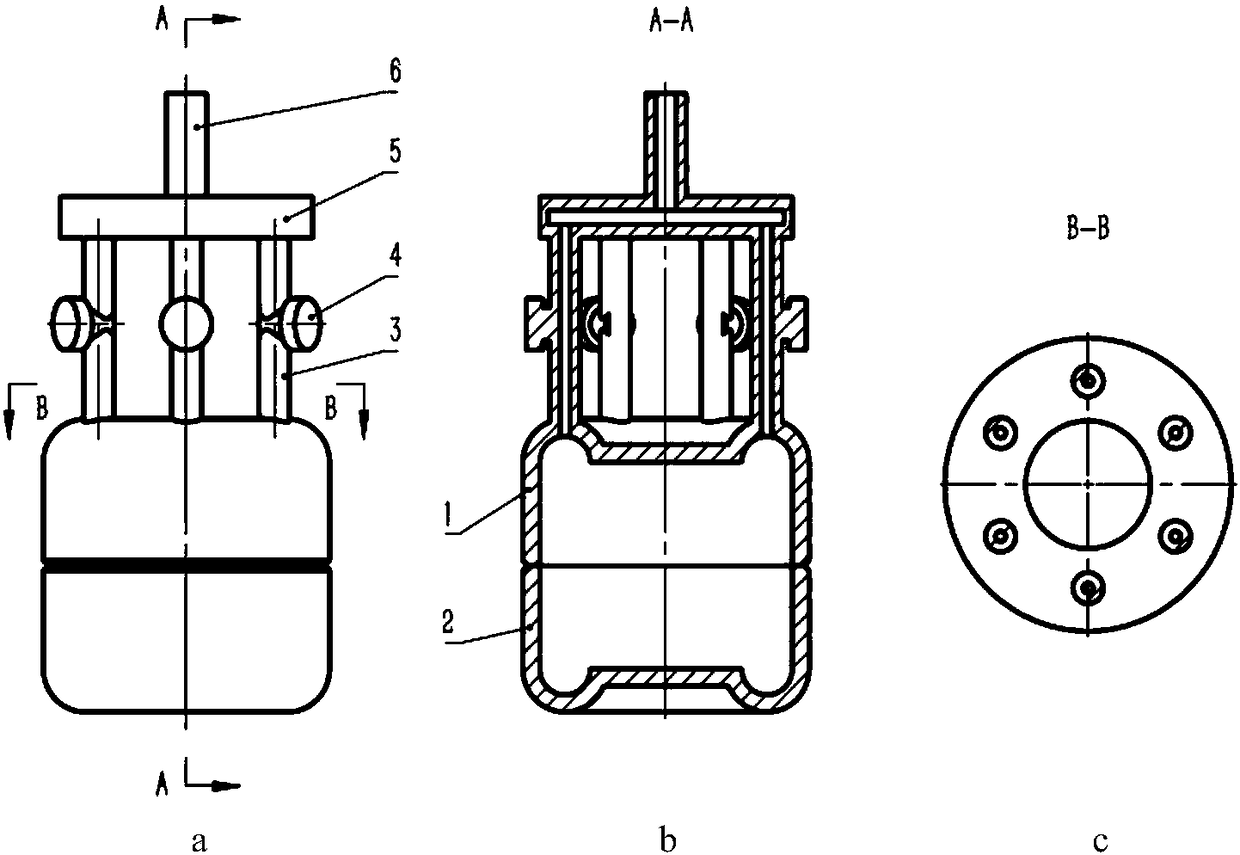

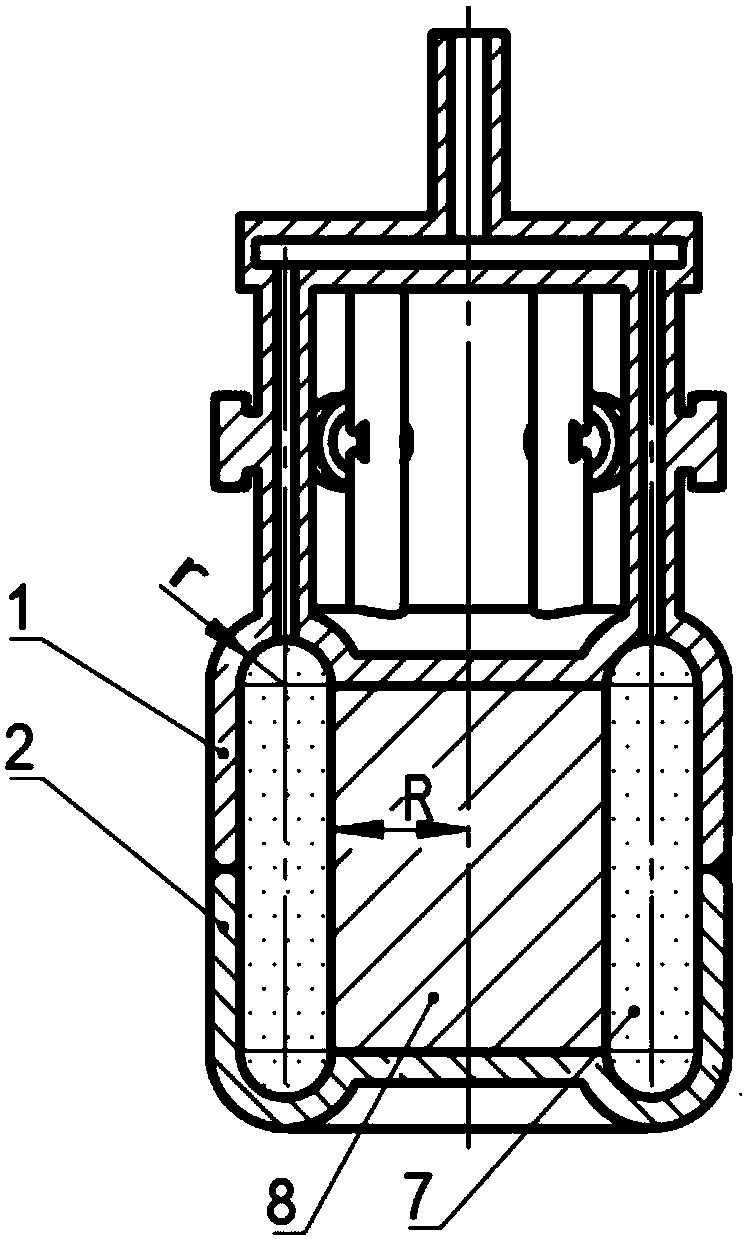

[0040] The present invention is a Ti 2 AlNb alloy and TiAl powder diffusion bonded annular piece preparation method.

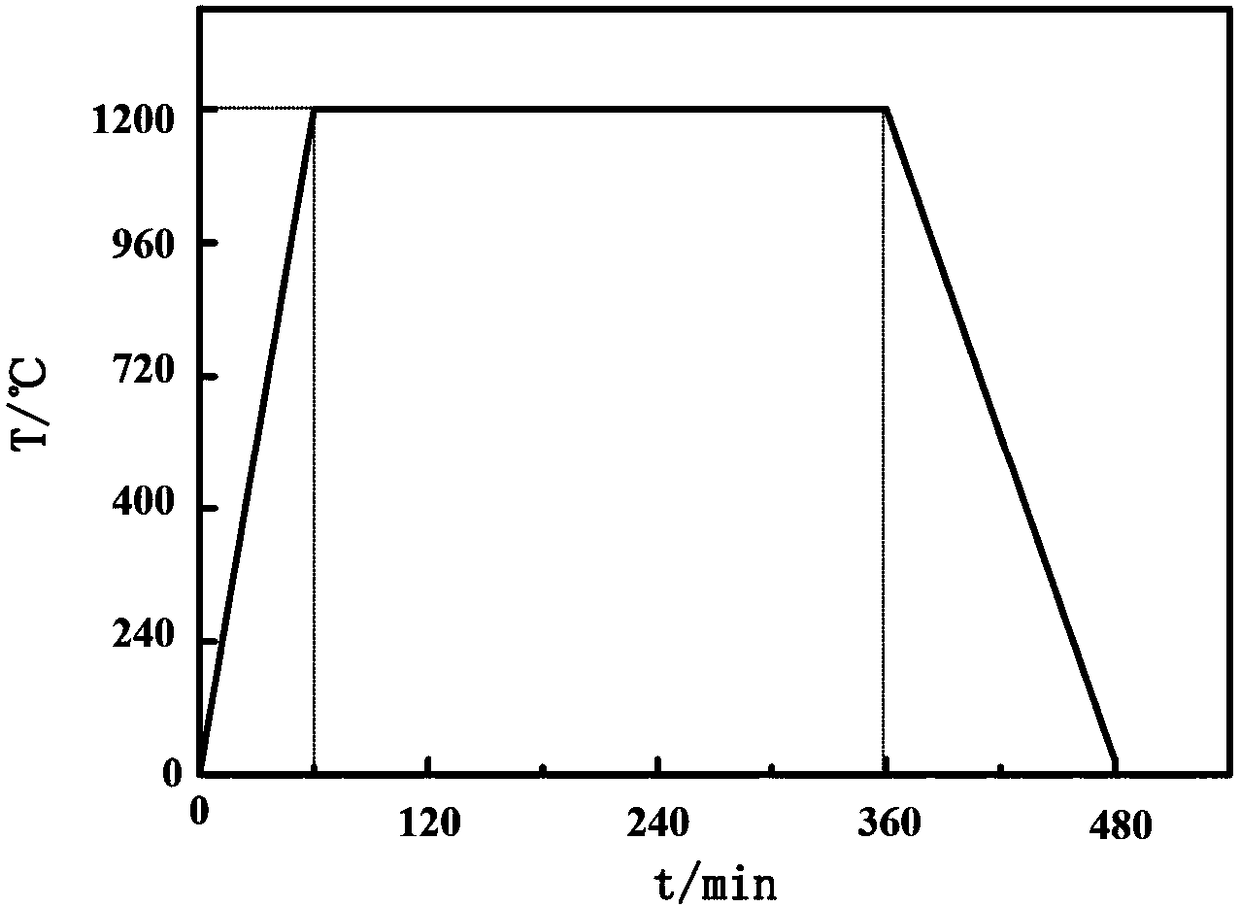

[0041] The specific process is:

[0042] Step 1, prepare materials. Described preparation comprises the Ti of making 2 AlNb discs and prepared TiAl alloy powders.

[0043] According to the design requirements, Ti 2 AlNb alloy forging blank processed into Ti 2 AlNb alloy disk. The Ti 2 The outer surface of the AlNb alloy disc adopts positive tolerance, and the precision is 0~+0.01mm. to Ti 2 The outer surface of the AlNb alloy disk is polished to a surface roughness of less than 0.4.

[0044] The amount of the TiAl alloy powder includes Ti 2 The filling amount of TiAl alloy powder around the AlNb disk 7, and the filling amount in the hemisphere of the inner surface of the end cap of the upper sheath 1 and the filling amount of the hemisphere of the inner surface of the end cap of the lower sheath 2 in the sheath assembly. Both the TiAl alloy powder f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com