Milling machine X-axis braking protection device

A braking protection, X-axis technology, applied in the field of milling machines, can solve the problems of burning the motor, reducing the life of the motor, easy to heat, etc., to reduce maintenance costs, avoid electrical failures, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

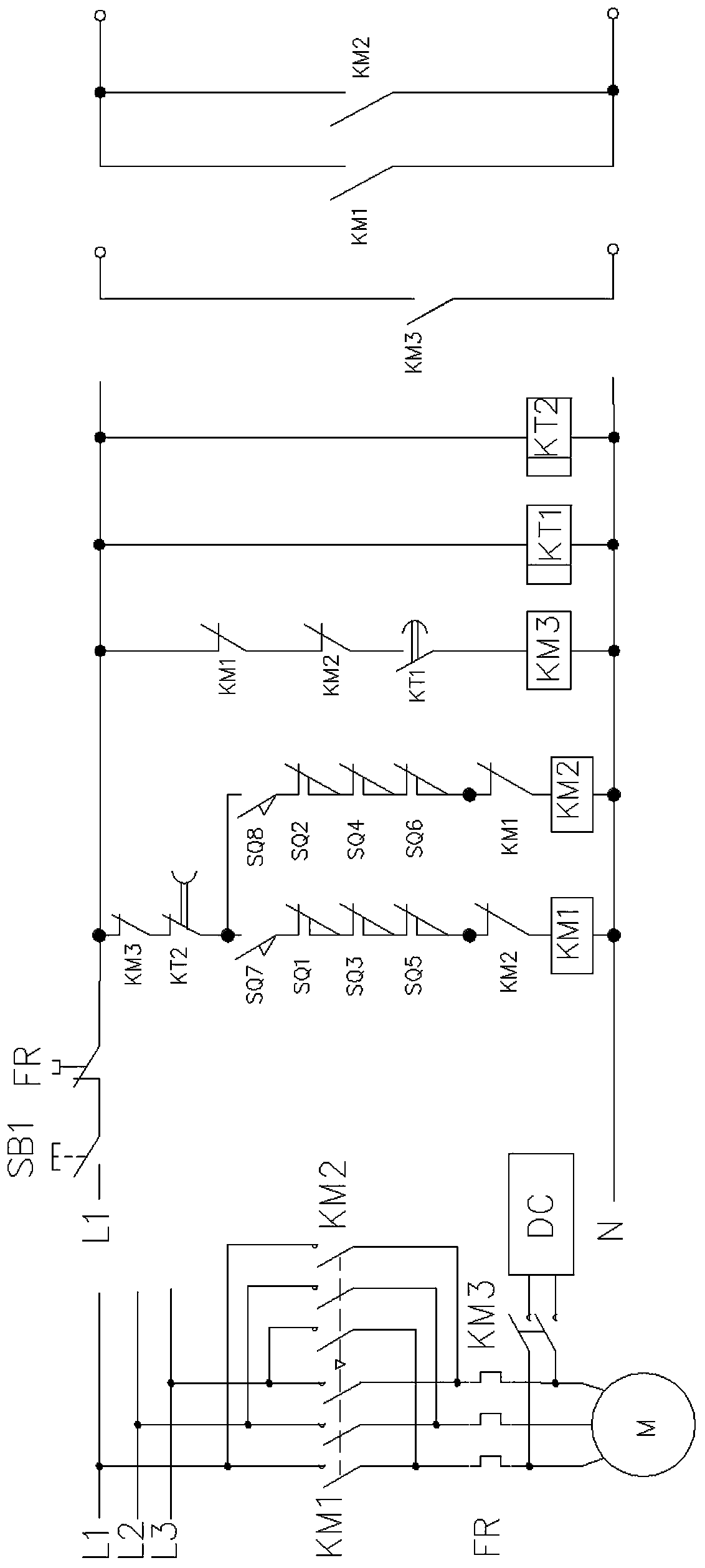

[0011] like figure 1 As shown, the present invention provides a X-axis braking protection device of a milling machine, including a first AC contactor KM1, a second AC contactor KM2, a thermal relay FR, a DC contactor KM3, a DC braking power supply DC, and a forward switch SQ7 , the reverse switch SQ8, the first time relay KT1 and the second time relay KT2; the main contacts of the first AC contactor KM1 and the second AC contactor KM2 are connected in reverse phase sequence, and the main contacts of the two AC contactors are connected in reverse phase sequence. The input end is connected to the three-phase power supply, the output end is connected to the thermal relay FR and the X-axis motor M of the milling machine in turn, the input end of the main contact of the DC contactor KM3 is connected to the DC braking power supply DC, and the output end is connected to the X-axis motor M of the milling machine;

[0012] The normally closed contact of the DC contactor KM3, the power-...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap