Sterile liquid rapid package switching system and packaging container and switching method of sterile liquid rapid package switching system

A technology for fast switching and packaging systems, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of extremely high installation and debugging precision of forming ring system, increased production stop time, long debugging cycle, etc., to save Packaging materials, improving efficiency, and the effect of not easy to pour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

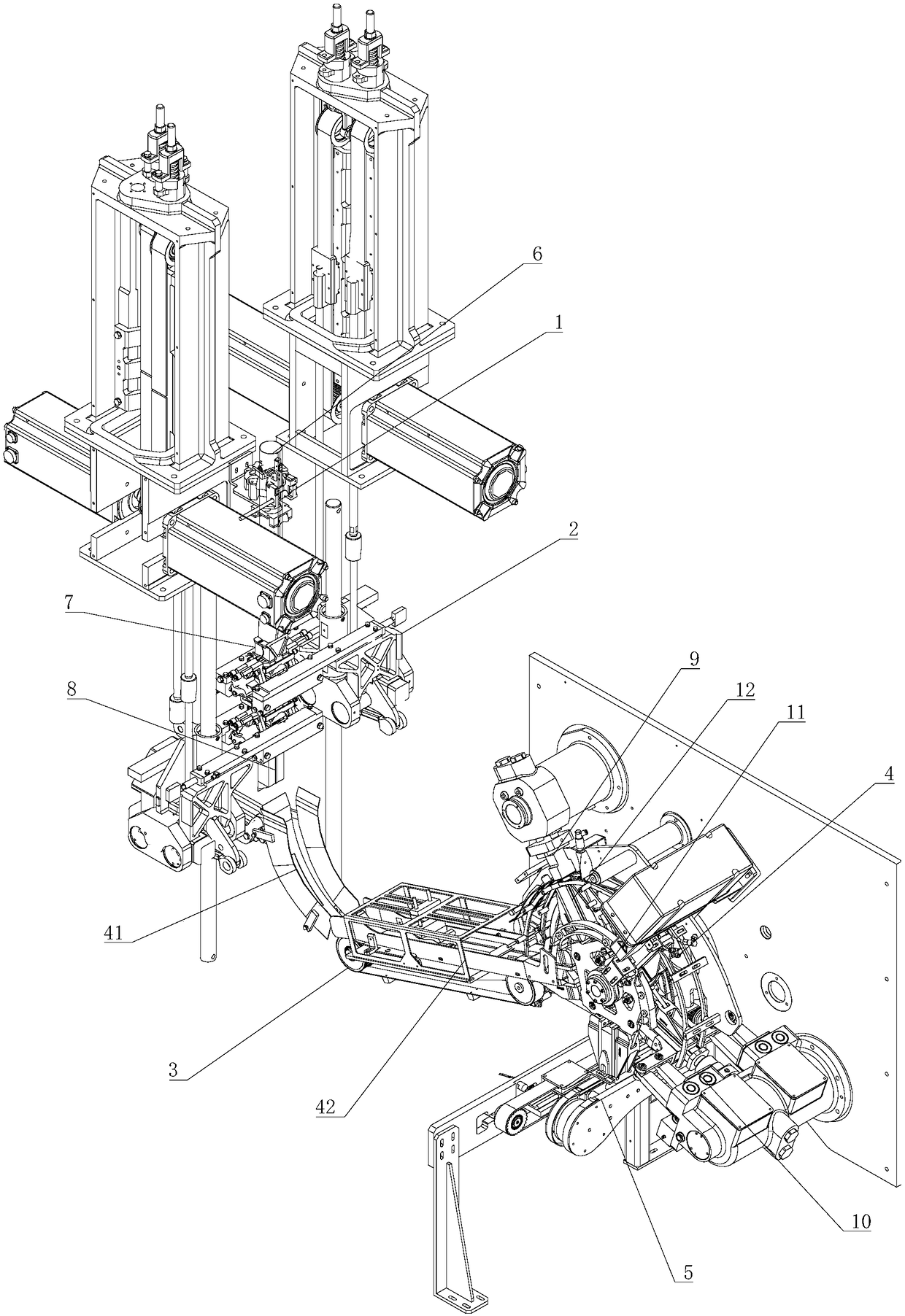

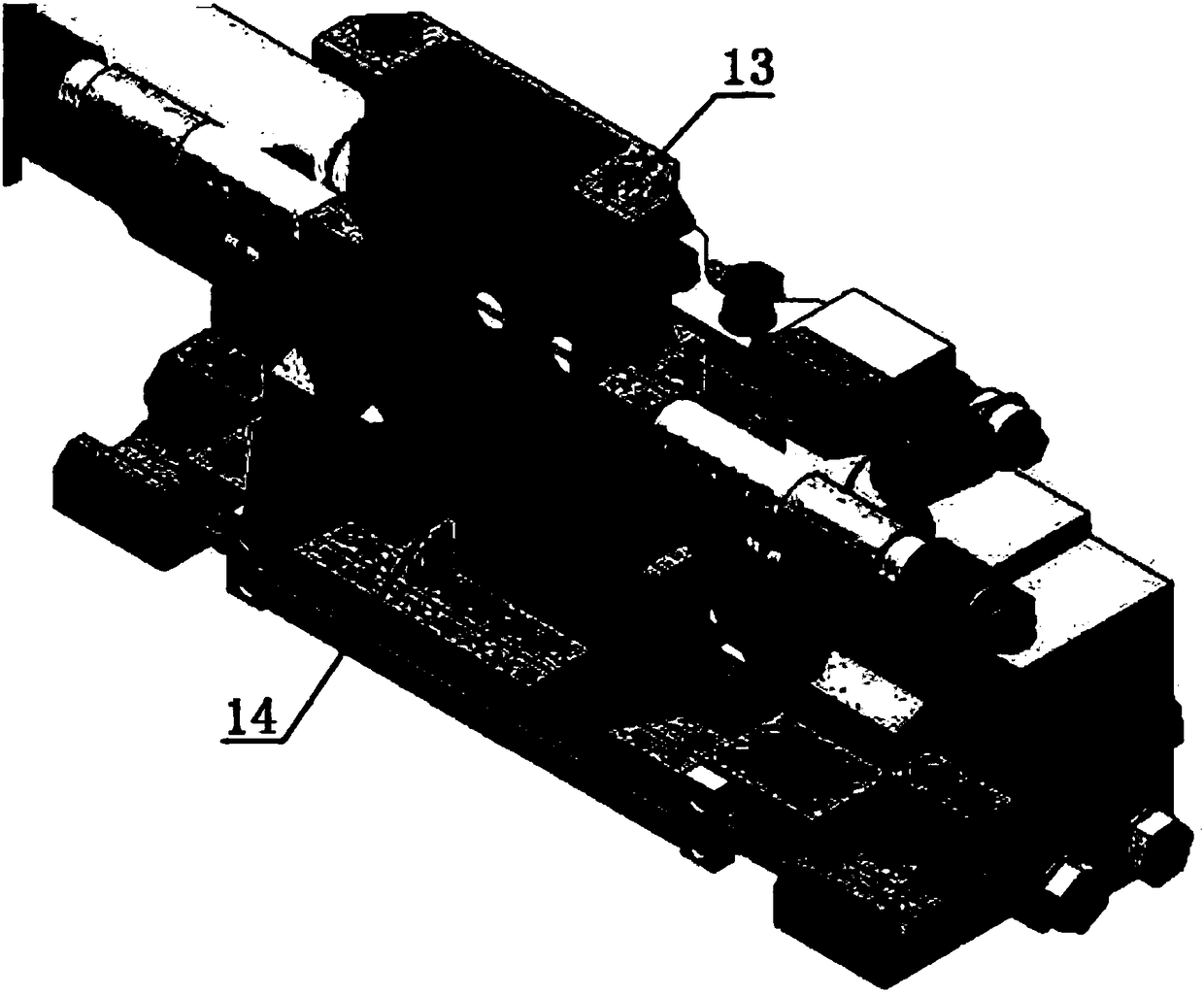

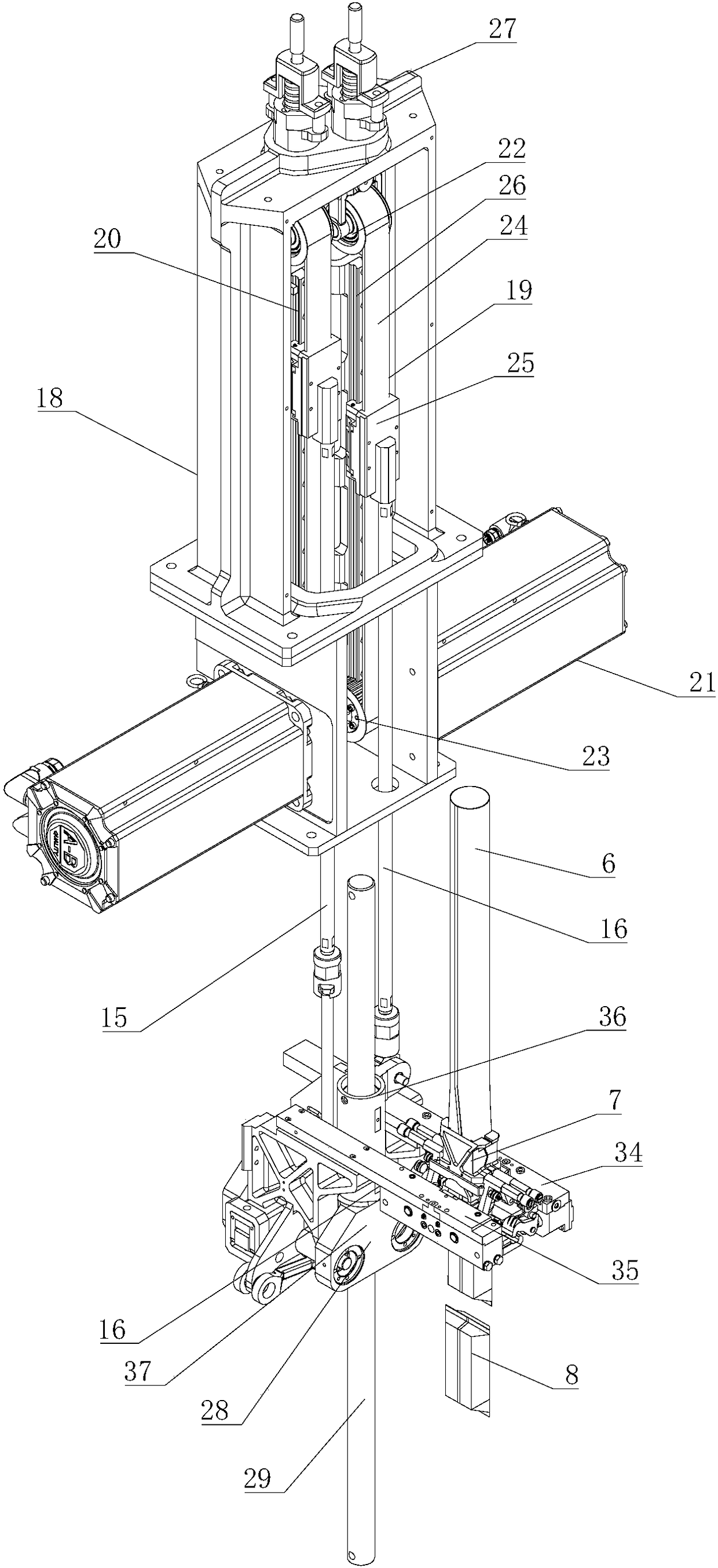

[0029] Such as figure 1As shown, a rapid switching packaging system for aseptic liquids includes a forming ring 1, a preliminary forming device 2, a conveying device 3, a terminal forming device 4, and a packaging device 5; the forming ring 1 is used to roll the packaging material into Tubular paper tube 6; the preliminary forming device 2 is provided with a set of forming dies 7, and the forming dies 7 of the two groups respectively carry out mold clamping processing on the end of the paper tube 6 to form an initial forming product 8, by adjusting The distance between the two groups of forming dies 7 can control the length of the initially formed product 8; the terminal forming device 4 includes a flanging mechanism 9, a bag pressing mechanism 10, and a turntable feeding mechanism 11; A plurality of mechanical grippers 12 are provided in the circumferential direction, and the flanging mechanism 9 and the pressing mechanism 10 are sequentially arranged on the periphery of the ...

Embodiment 2

[0033] Such as Figure 5 As shown, a packaging container is produced by a kind of aseptic liquid quick switching packaging system described in Example 1, the length W=46mm of the described packaging container, the width L=46mm, the height H=95mm, its capacity The specification is 200ml.

Embodiment 3

[0035] Such as Figure 5 As shown, a packaging container is produced by a kind of aseptic liquid quick switching packaging system described in Example 1. The W=46mm of the packaging container, the width L=46mm, the height H=118.5mm, and its capacity The specification is 250ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Section length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com