Cable winding machine with even winding function

A wire take-up and winding technology, applied in the field of wires and cables, can solve the problems of uncertainty, uneven winding of wires and cables, etc., and achieve the effects of stable operation, ingenious structure, and neatly wound cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

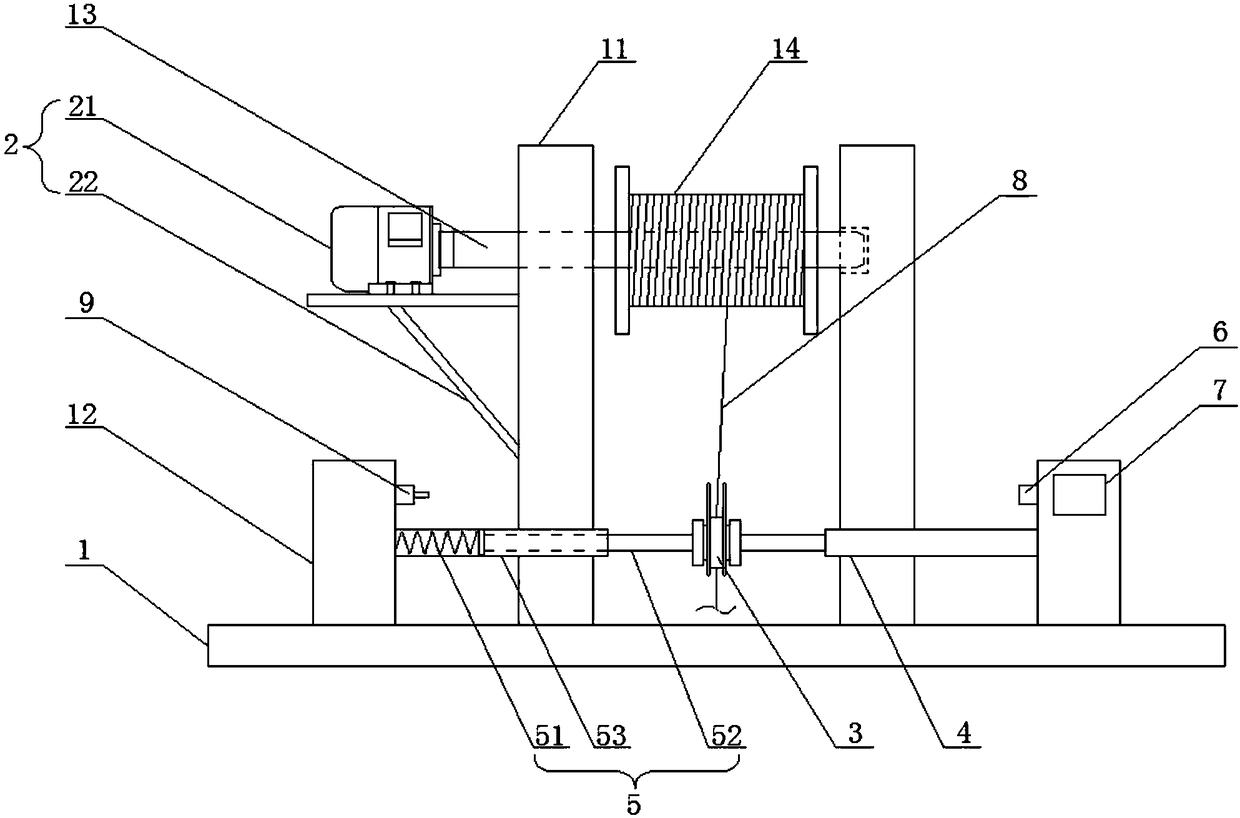

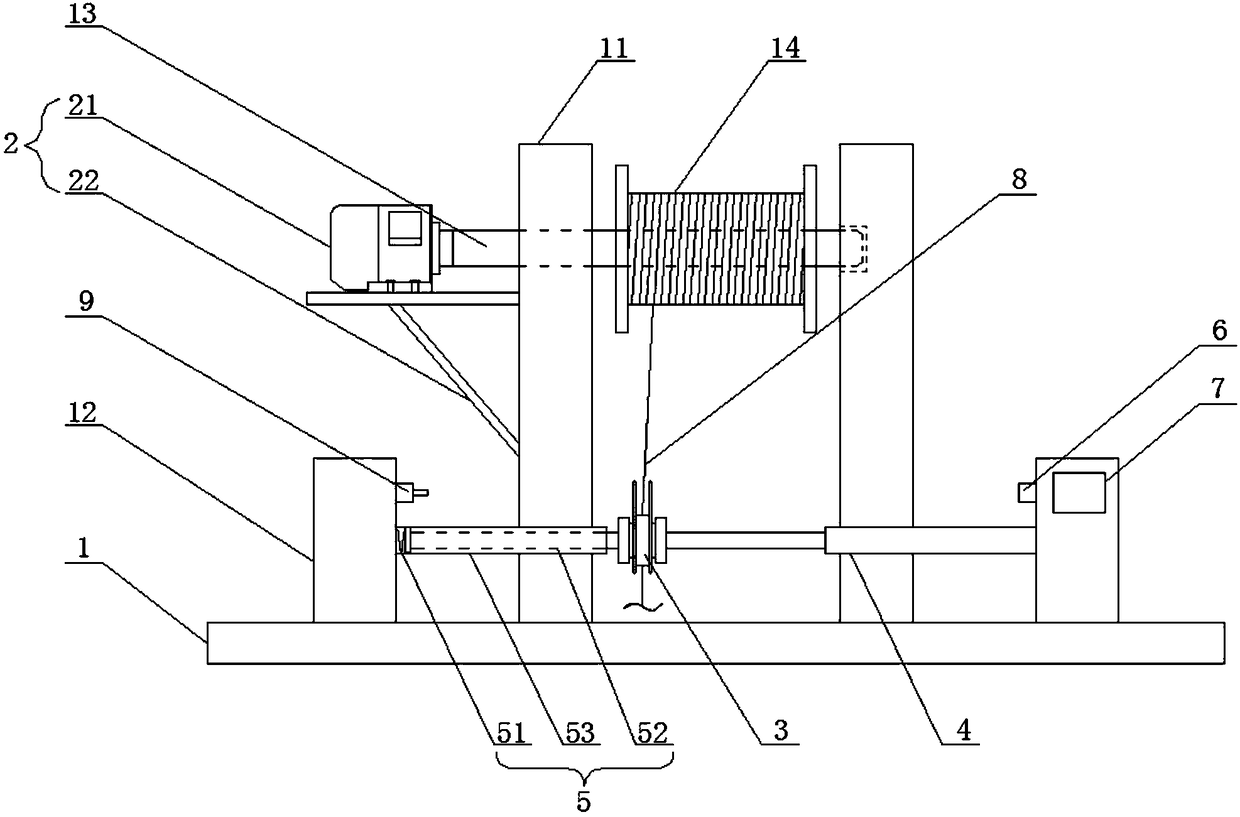

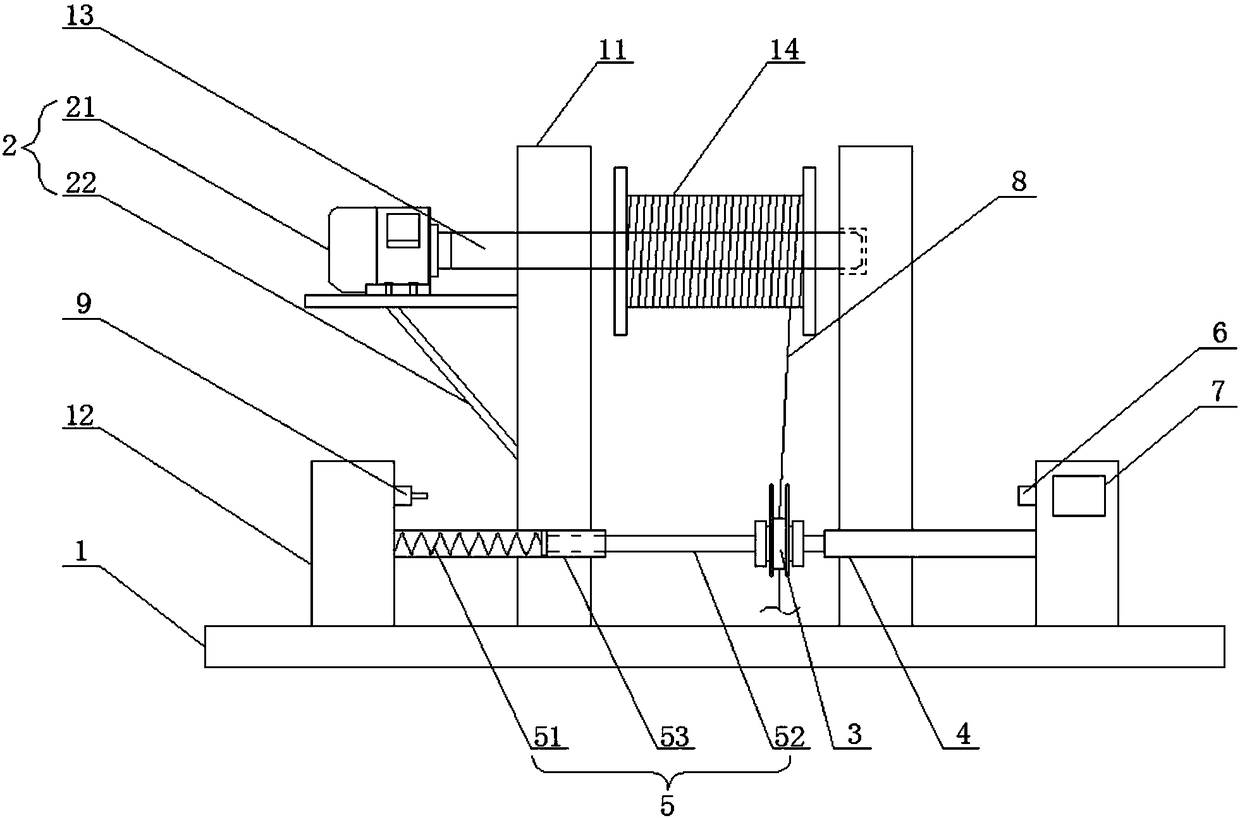

[0028] The specific embodiment of the present invention is as Figure 1-4 As shown, a cable take-up machine capable of uniform winding includes a base 1, wherein the base 1 is provided with two oppositely arranged support frames 11, and the upper parts of the two support frames 11 are provided with horizontally arranged and axially rotating The shaft 13 is provided with a cable reel 14 that rotates synchronously with it; the base 1 is also provided with two mounting seats 12 that are oppositely arranged and parallel to the two support frames 11. Between the two mounting seats 12 There is an eccentric guide wheel 3 that rotates in the vertical direction and moves horizontally at a constant speed. By setting the cable reel 14 on the shaft 13 that rotates synchronously with it, it can be co-located between the two mounting seats 12 to move horizontally at a constant speed. The eccentric guide wheel 3, the cable 8 will be evenly and neatly wound on the cable reel 14, so as to avoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com