A high-performance lithium complex grease with improved dropping point and additive sensitivity and its preparation process

A base grease, complex lithium-based technology, applied in lubricating compositions, petroleum industry and other directions, can solve the problems of poor lubricating grease sensitivity, easy to drip oil, weakening, etc., to inhibit catalytic oxidation, prolong service life and reduce accumulated temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

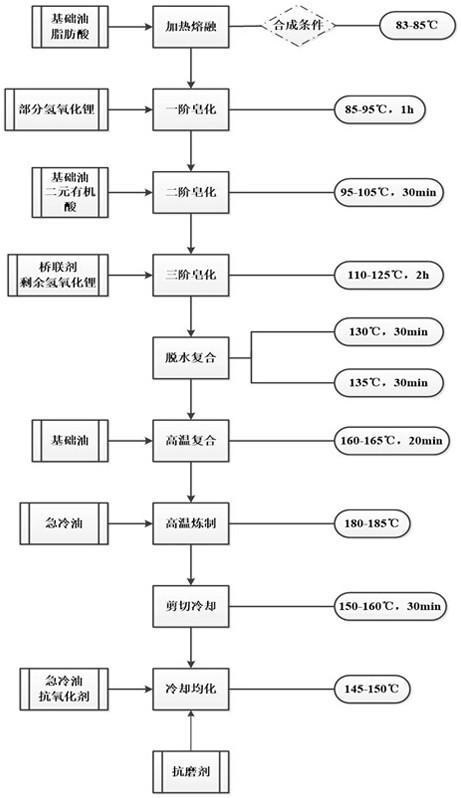

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, high-performance composite lithium-based grease in which the droppoint and the additive sensibility is improved, including the following components: base oil (two different viscosity mineral lubricants 400Sn, 150Bs mixtures, the two quality Comparison is 1: 1) 310 copies, C 12 25 parts of stearic acid, 12 partial decanoate, 12 parts of lithium hydroxide, 14 parts of saponated water, 11 parts of sebacalic acid, 1.1 parts of diphenyrene, 89 cases of quenched oil, zinc dialkyl dithiophosphate 6 copies of dialkyl dithiocarcone molybdenum.

[0032] The preparation steps of the above high-performance composite lithium-based grease are as follows:

[0033] (1) First-order saponification: 215 basic oils and 25 copies 12 Steaic acid was added to the open reactor was heated at 85 ° C for 30 min, and the stirring rate was 110 r / min, c 12 After all of the stearic acid dissolved, 6 parts of lithium hydroxide, 7 disadvantaged water were added, warmed to 95 ° C, and ...

Embodiment 2

[0043] In this embodiment, high-performance composite lithium-based grease in which the droppoint and the additive sensibility is improved, including the following components: base oil (two different viscosity mineral lubricants 400Sn, 150Bs mixtures, the two quality The ratio is 1: 1) 320 parts, C12 stearic acid 27 parts, 14 parts of sebacate, 15 parts of lithium hydroxide, 14 pieces of saponate, 13 parts of sebacalic acid, 1.4 parts of diphenyrene, emergency oil 86 Part of zinc, dialkyl dithiophosphate, 4 parts of diethalkyl dithiocarbonate.

[0044] The preparation steps of the above high-performance composite lithium-based grease are as follows:

[0045] (1) First-order saponification: 220 parts of the base oil and 27 parts of C12 stearic acid were added 85 ° C for 15 min, and the stirring rate was 110 r / min, and the C12 stearic acid was dissolved, and 7 parts of hydrogen was added. Lithium oxide, 10 disadvantaged water, warmed to 95 ° C, increase the stirring rate to 130 r ...

Embodiment 3

[0058] In this embodiment, high-performance composite lithium-based grease in the increasing drop point and additive sensitivity is based on weight parts, including the following components: base oil (polyether and polysiloxane mixtures, the two mass ratios 1: 1) 315 parts, 30 parts of 12-hydroxy dialkyl acid, 15 butyrate acid, 13 parts of lithium hydroxide, 12 parts of saponified water, 11 serothellic acid diethylhexyl, 2,6-second uncle 1.0 parts of toluene phenol, 92 parts of acute cold oil, 12 parts of dialkyl dithiophosphate.

[0059] The preparation steps of the above high-performance composite lithium-based grease are as follows:

[0060] (1) First-order saponification: 210 parts of the foundation oil and 30 parts of 12-hydroxy dialkyl acid were added 85 ° C for 15 min at 85 ° C, the stirring rate was 100 r / min, 12-hydroxy dialkyl acid After all dissolved, 8 parts of lithium hydroxide, 8 disadvantaged water were added, and the temperature was raised to 90 ° C, and the stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com