Fabricated H-shaped steel trestle plate

A technology of H-beam and trestle board, used in bridges, bridge parts, bridge construction, etc., can solve the problems of low connection strength, hidden dangers, low assembly efficiency, etc., and achieve outstanding safety performance, high support strength, and rapid assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

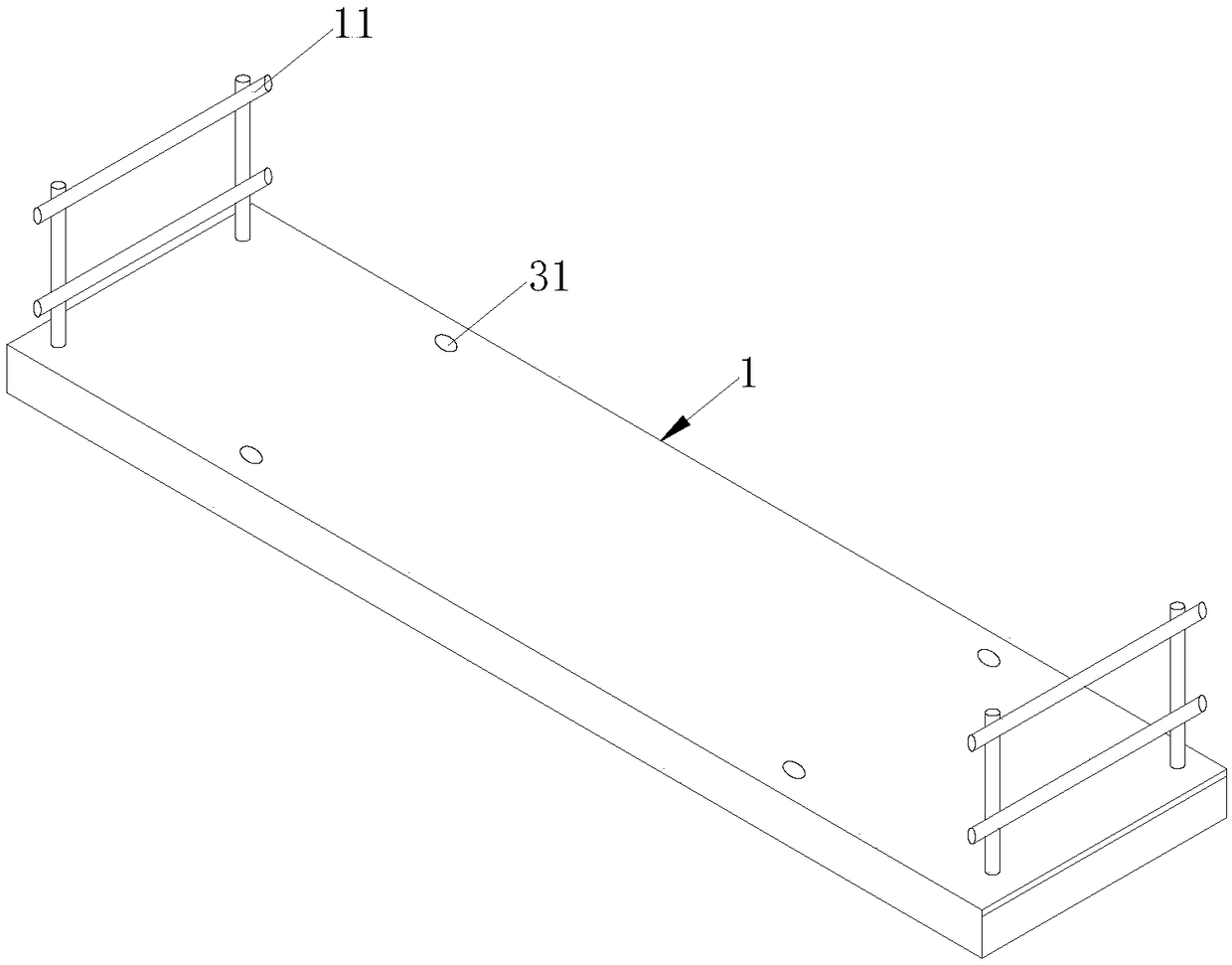

[0021] see Figure 1-3 , an assembled H-shaped steel trestle board, including a trestle board main body 1, the upper end surface of the trestle board main body 1 is provided with a guardrail 11, and the trestle board main body 1 provides a stable support plane for the construction party, thereby ensuring that vehicles and labor can be safely, Stable transportation operation, the guardrail 11 is symmetrically arranged on both sides of the trestle board main body 1, the guardrail 11 is vertically arranged on the outer surface of the trestle board main body 1, the guardrail 11 strengthens the safety protection function of the trestle board main body 1, and prevents falling. The bottom of 11 is fixedly connected with the trestle board main body 1, and the inner side of the trestle board main body 1 is provided with multiple sets of connecting H-shaped steels 2 with the same model, and the connecting H-shaped steels 2 are fixedly welded to each other, and the connecting H-shaped ste...

Embodiment 2

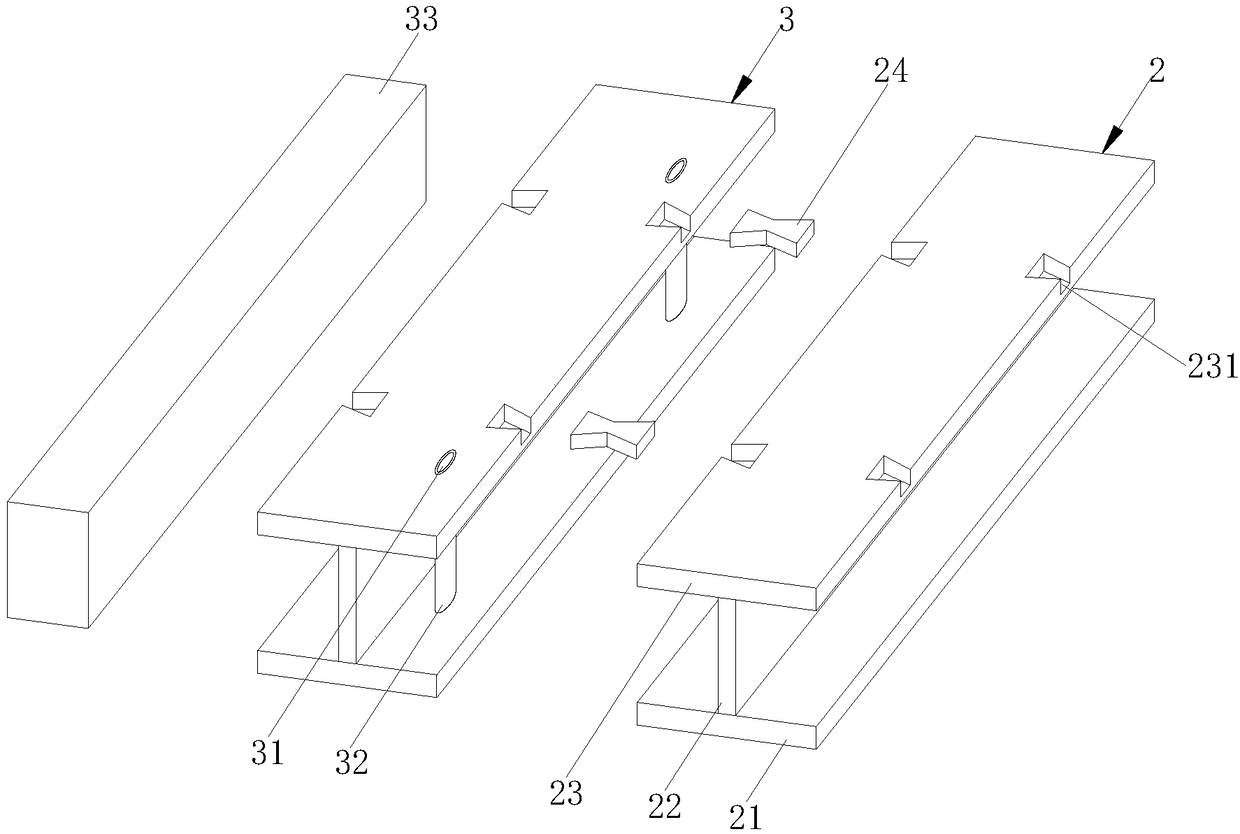

[0024] see Figure 4-5 , an assembled H-shaped steel trestle board, including a trestle board main body 1, the upper end surface of the trestle board main body 1 is provided with a guardrail 11, and the trestle board main body 1 provides a stable support plane for the construction party, thereby ensuring that vehicles and labor can be safely, Stable transportation operation, the guardrail 11 is symmetrically arranged on both sides of the trestle board main body 1, the guardrail 11 is vertically arranged on the outer surface of the trestle board main body 1, the guardrail 11 strengthens the safety protection function of the trestle board main body 1, and prevents falling. The bottom of 11 is fixedly connected with the trestle board main body 1, and the inner side of the trestle board main body 1 is provided with multiple sets of connecting H-shaped steels 2 with the same model, and the connecting H-shaped steels 2 are fixedly welded to each other, and the connecting H-shaped ste...

Embodiment 3

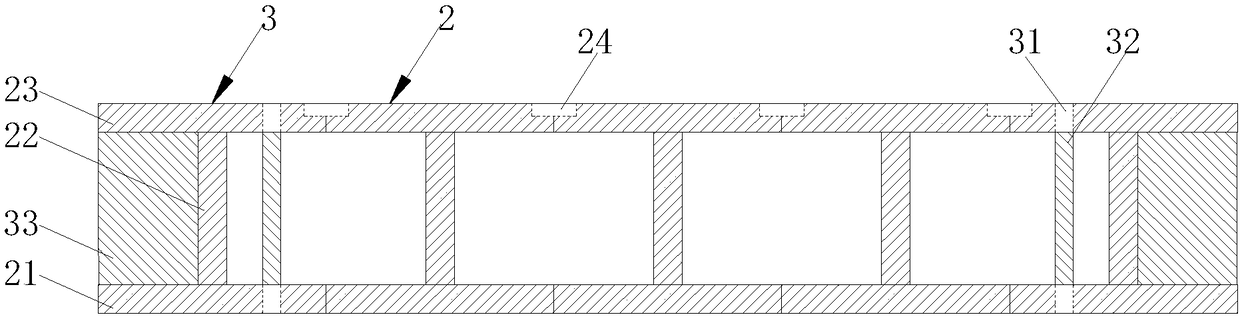

[0027] see Figure 6 , an assembled H-shaped steel trestle board, including a trestle board main body 1, the upper end surface of the trestle board main body 1 is provided with a guardrail 11, and the trestle board main body 1 provides a stable support plane for the construction party, thereby ensuring that vehicles and labor can be safely, Stable transportation operation, the guardrail 11 is symmetrically arranged on both sides of the trestle board main body 1, the guardrail 11 is vertically arranged on the outer surface of the trestle board main body 1, the guardrail 11 strengthens the safety protection function of the trestle board main body 1, and prevents falling. The bottom of 11 is fixedly connected with the trestle board main body 1, and the inner side of the trestle board main body 1 is provided with multiple sets of connecting H-shaped steels 2 with the same model, and the connecting H-shaped steels 2 are fixedly welded to each other, and the connecting H-shaped steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com