Aerated concrete slab

A technology of aerated concrete slabs and concrete slabs, which is applied to building materials, building components, building insulation materials, etc., can solve problems such as water seepage and water leakage at connecting transverse joints, and achieve the effects of reducing costs, strengthening waterproof effects, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

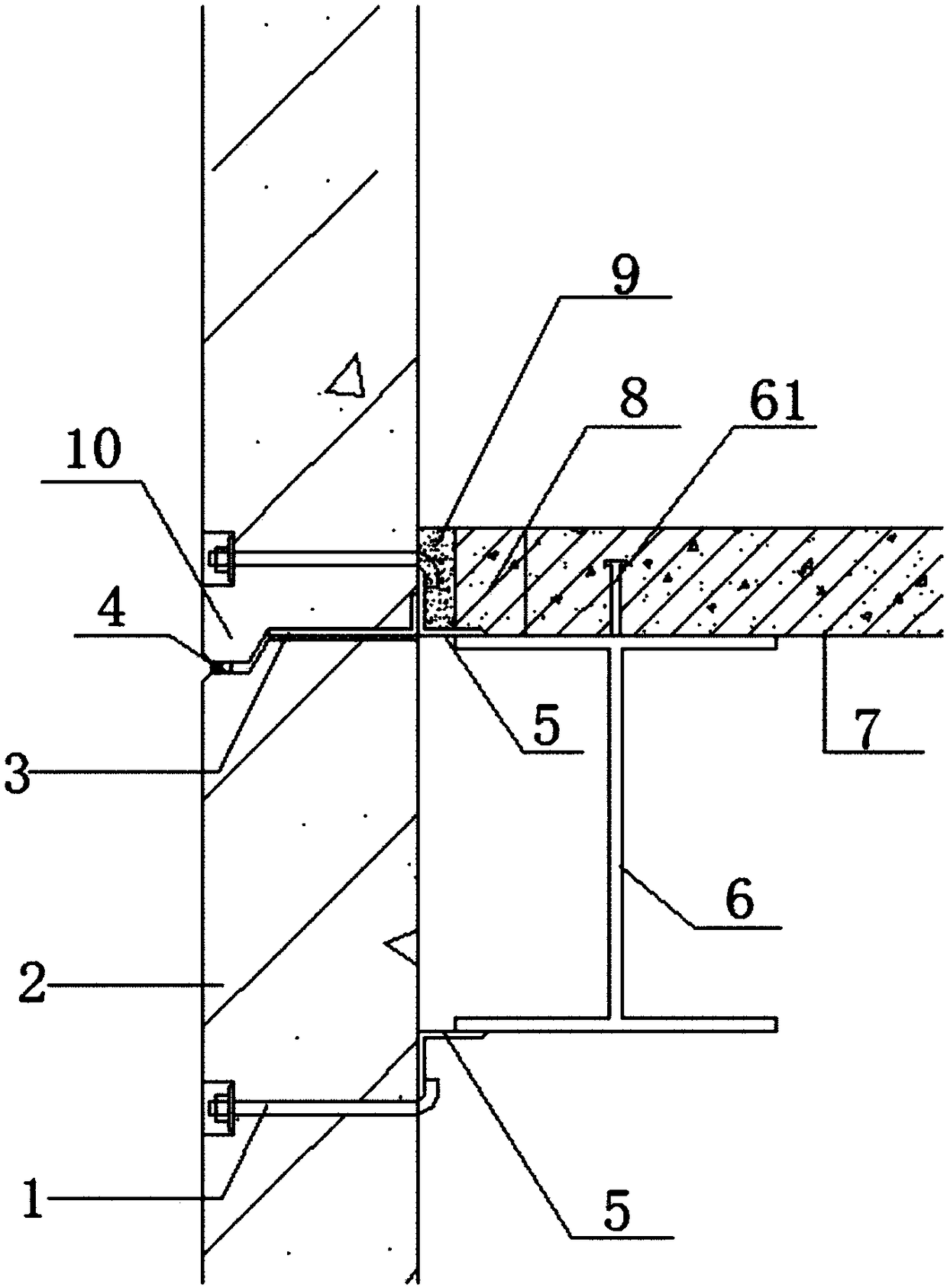

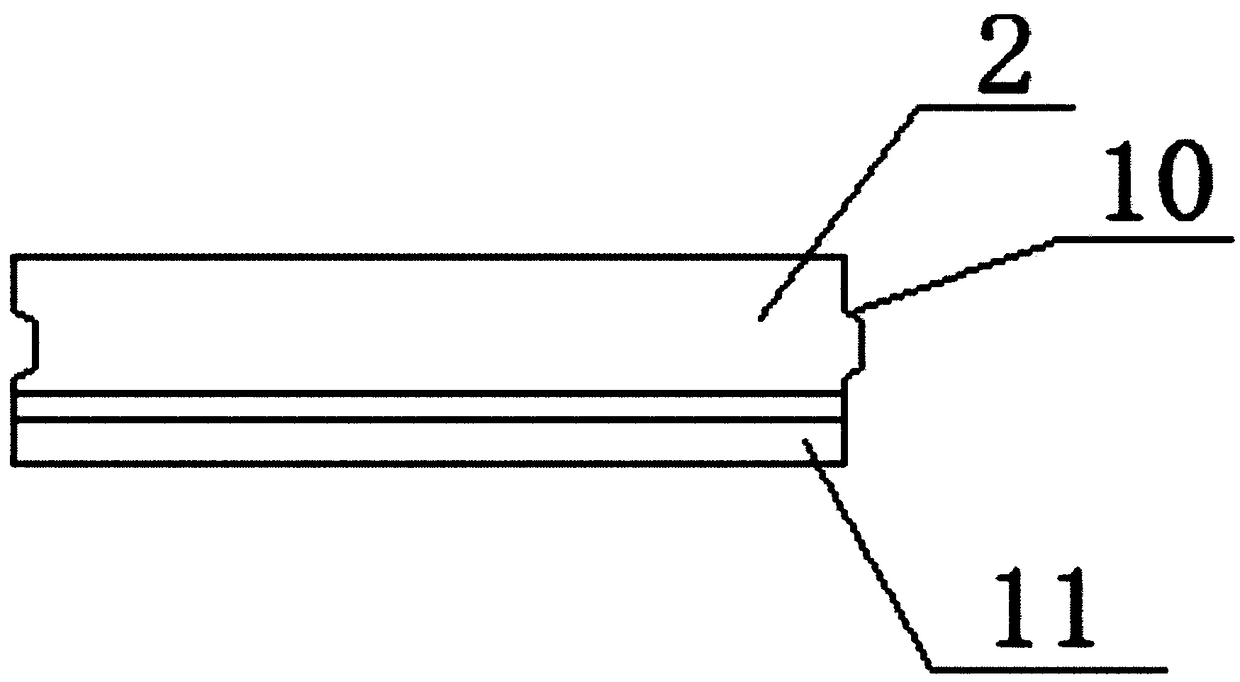

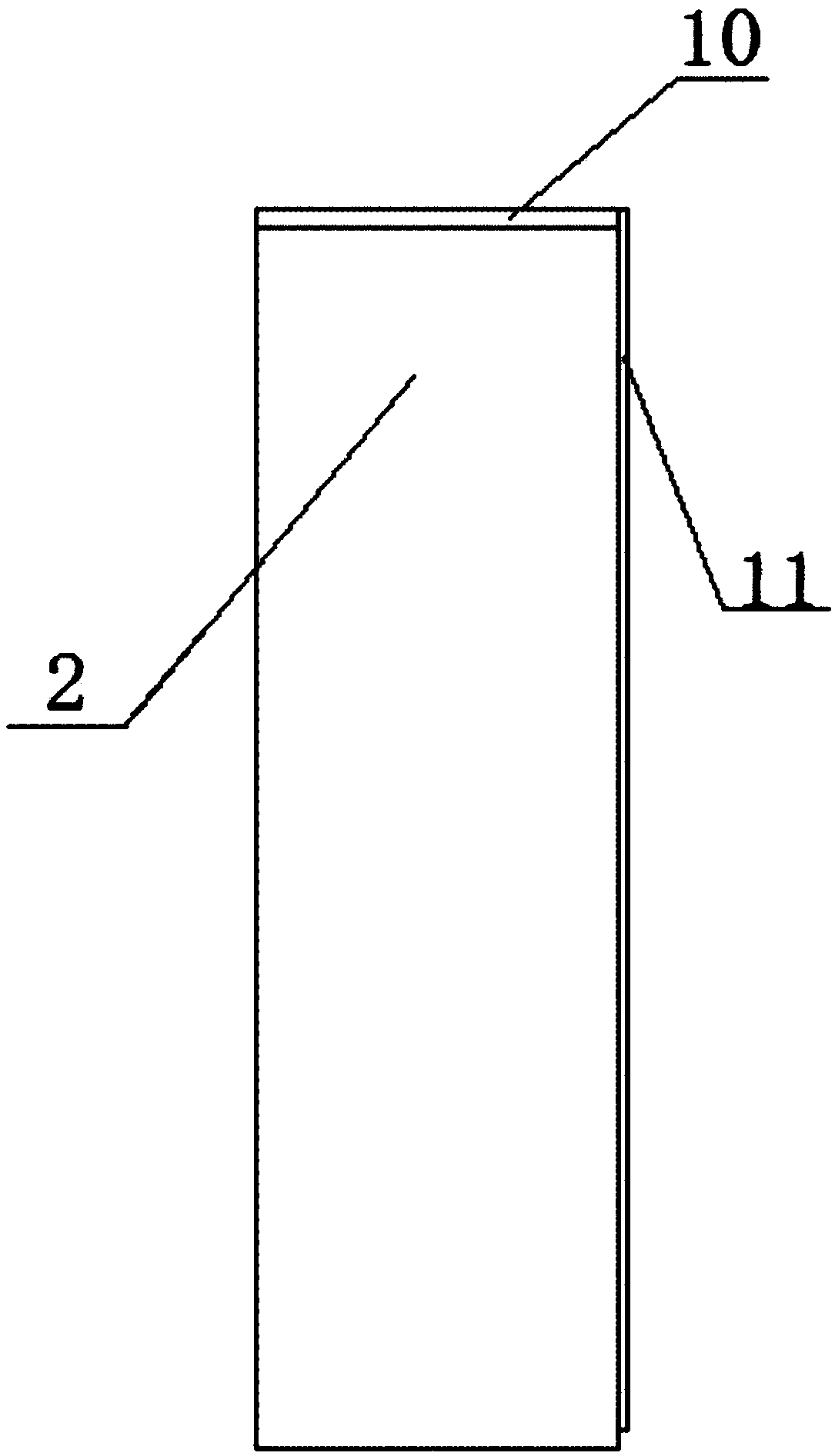

[0042] The autoclaved aerated concrete slab structure of the present embodiment, as figure 1 As shown, the autoclaved aerated concrete slabs 2 are vertically connected to each other, and the two top ends of the autoclaved aerated concrete slabs 2 are steps 10 opposite to each other, which are staggered when connected; one of the connected transverse joints is vertically fixed Floor 7; the corner formed by the floor 7 and the inner wall connected to the autoclaved aerated concrete slab 2 is fixedly connected to the beam 6 . The surface of the concrete slab is sprayed with waterproof paint, and its proportion is as follows

[0043] The waterproof coating includes an adhesive, an aqueous solution, and a desiccant, wherein the adhesive has a weight percentage of 70-80, the aqueous solution has a weight percentage of 5-15, and the desiccant has a weight percentage of 5. 10 parts of rubber powder, the particle size of which is not greater than 1 mm; adjusting the weight percentage ...

Embodiment 2

[0050] The basic structure of the autoclaved aerated concrete slab structure of this embodiment is the same as that of Embodiment 1. The difference and improvement lies in that the beam 6 is an I-shaped steel beam, and the upper surface thereof is fixed with a rivet 61, which is fixed to the floor 7 by the rivet 61. connect. The floor slab 7 is tightened by the I-beam, and the floor slab 7 is close to the connecting transverse joint to avoid water seepage. The inner wall of the autoclaved aerated concrete slab 2 is also fixed with two angle steels 5 distributed up and down, and the upper angle steel 5 is attached to the connecting transverse joint formed by the two autoclaved aerated concrete slabs 2, and supported on the bottom of the floor 7, The bottom angle steel 5 is supported on the bottom of the I-beam beam. Improve the stability of I-beam fixing. The surface of the concrete slab is sprayed with waterproof paint, and its proportion is as follows

[0051] The waterpro...

Embodiment 3

[0057] The basic structure of the autoclaved aerated concrete slab structure of this embodiment is the same as that of the embodiment 2, the difference and improvement lies in that two angle steels 5 are fixed on the inner wall of the autoclaved aerated concrete slab 2 through two bolts 1 . To improve the fixed stability of the angle steel 5. The connection between the floor 7 and the autoclaved aerated concrete slab 2 is filled with fine stone concrete caulking 8 , and the floor 7 and the autoclaved aerated concrete slab 2 are connected together through the transition of the fine stone concrete slab 8 . The connection between the fine stone concrete caulking 8 and the autoclaved aerated concrete slab 2 is filled with an elastic material caulking 9, which acts as a buffer to avoid and reduce stress changes on the floor 7 due to environmental changes. The surface of the concrete slab is sprayed with waterproof paint, and its proportion is as follows

[0058] The waterproof coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com