A kind of oil pipe lowering method

A tubing and lower layer technology, which is applied in the field of tubing running, can solve problems such as irregular tubing make-up curves, unstable tubing pressure tests, and safety risks for offshore operators, so as to improve the timeliness of well completion operations, improve service life, optimize The effect of the number of pressure tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

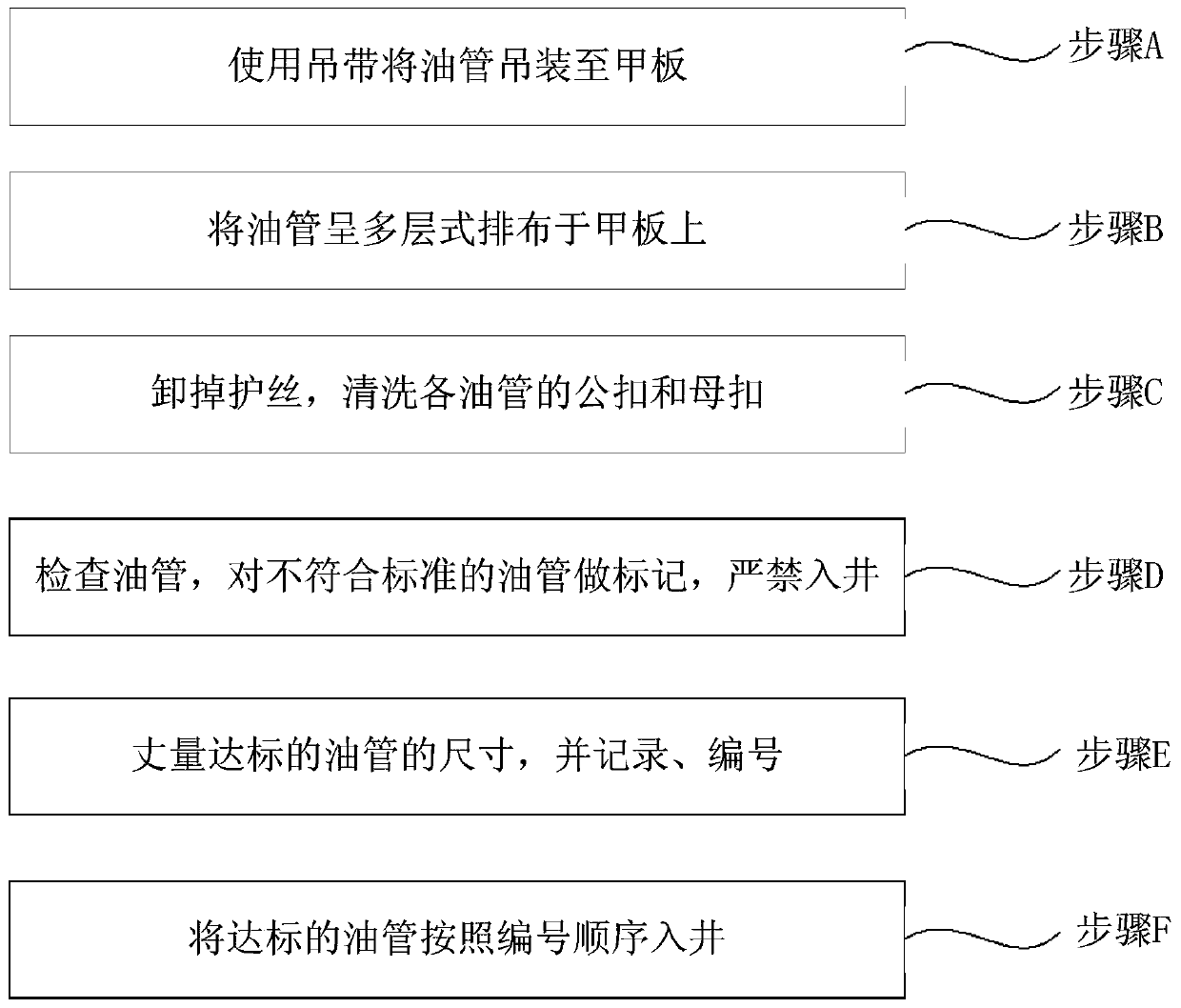

[0053] see Figure 1 to Figure 3 , the tubing running method provided in this embodiment includes the following steps:

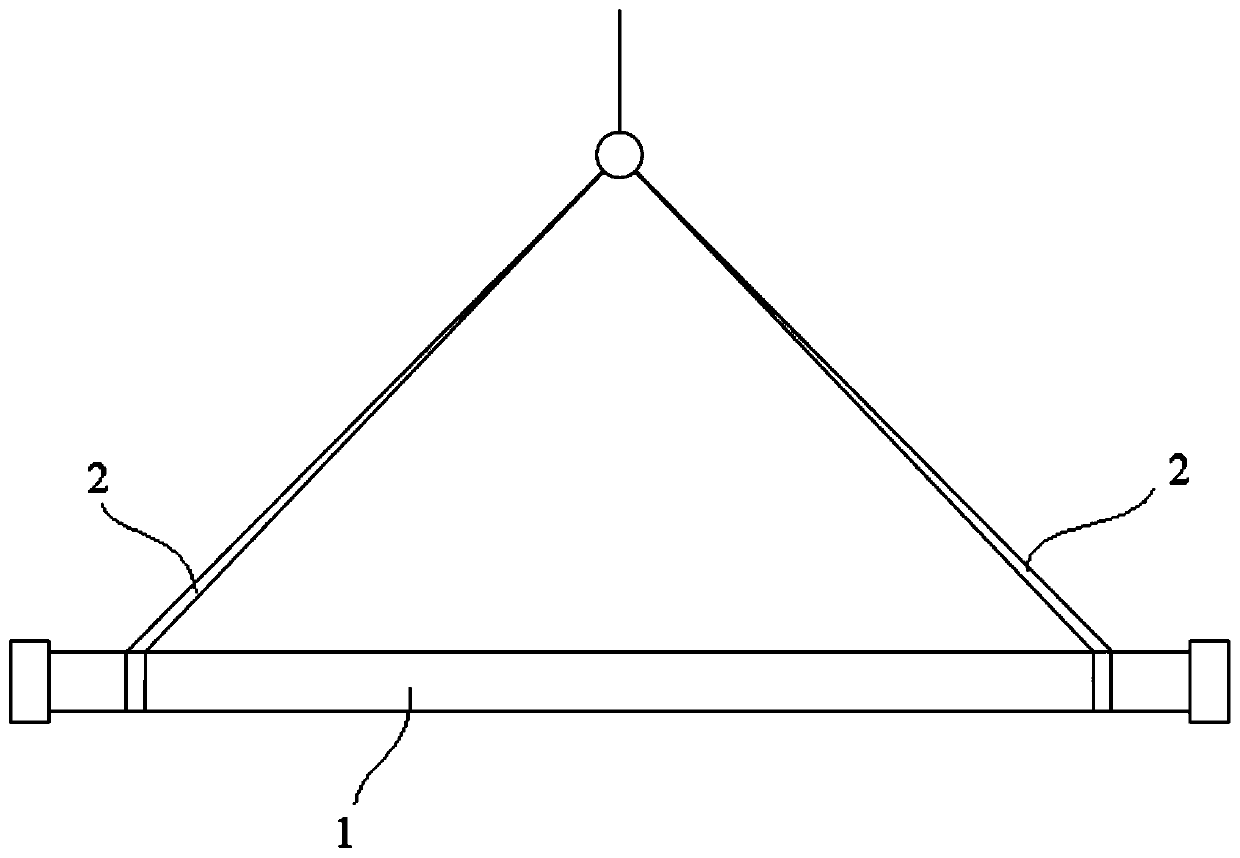

[0054] In step A, the oil pipe is hoisted to the deck by using a sling; compared with the wire rope in the prior art, the sling can avoid damage to the outer wall of the oil pipe.

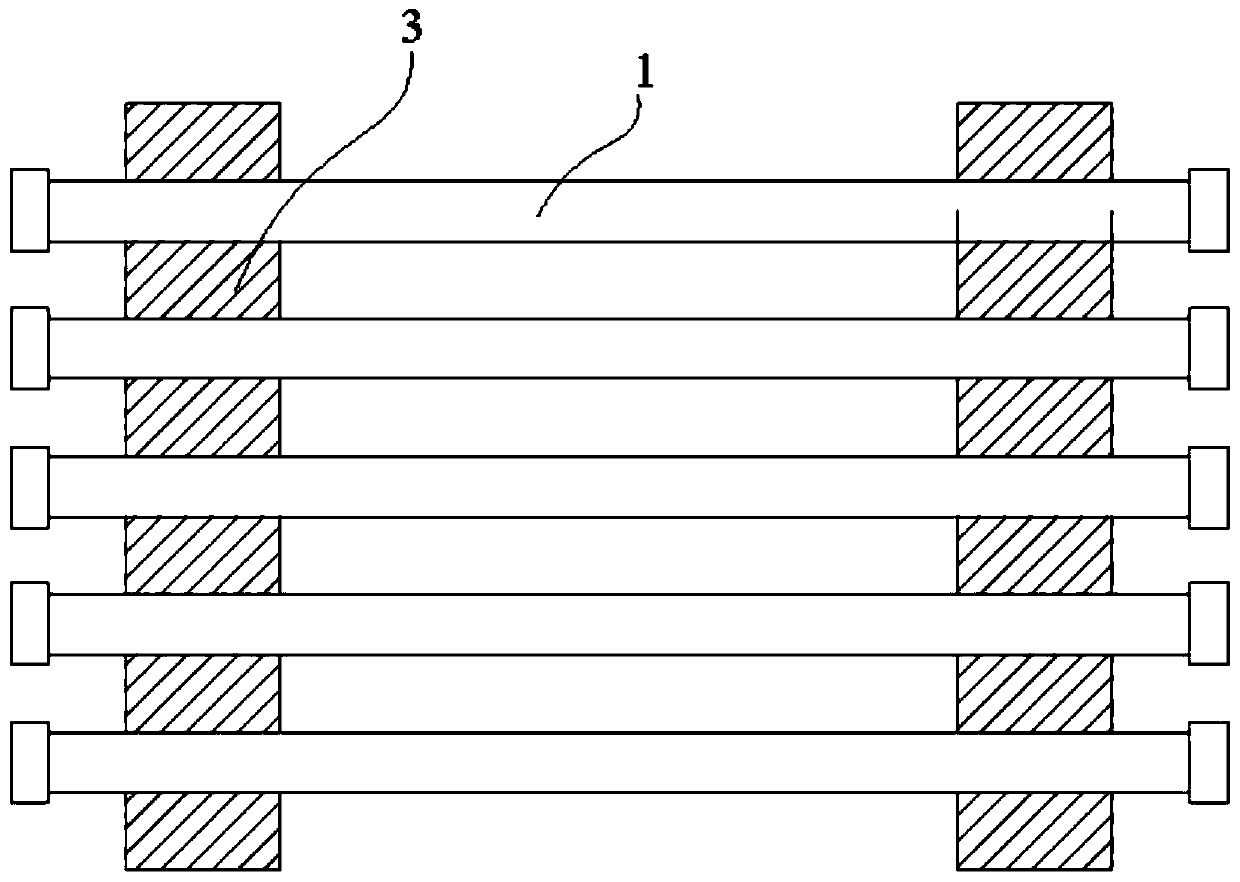

[0055] Step B: Arrange the oil pipes on the deck in a multi-layered manner, use sleeper pads between the adjacent upper and lower oil pipes, and arrange the adjacent oil pipes on the same layer at intervals to prevent the oil pipes from colliding with each other and facilitate Follow-up cleaning work. The oil pipes are arranged on the deck in a multi-layer manner, and as many oil pipes as possible can be placed in the limited space of the deck, and various treatments can be performed on the oil pipes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com