Plant root puncture-resistant adhesive and preparation method thereof

A technology of adhesives and plant roots, applied in the direction of adhesives, mineral oil hydrocarbon copolymer adhesives, adhesive types, etc., can solve the problems that the base layer of the coil cannot be left, the asphalt layer cannot be removed, and the base layer cannot be connected, etc. , to achieve the effects of good health, good practical value and social benefits, and high product benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

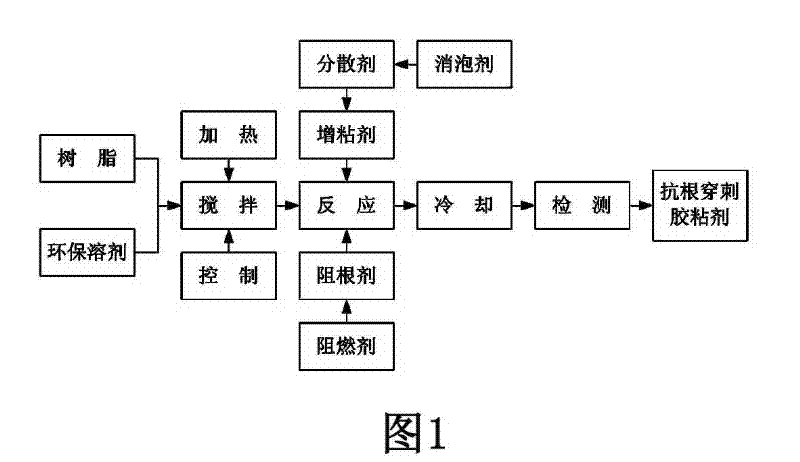

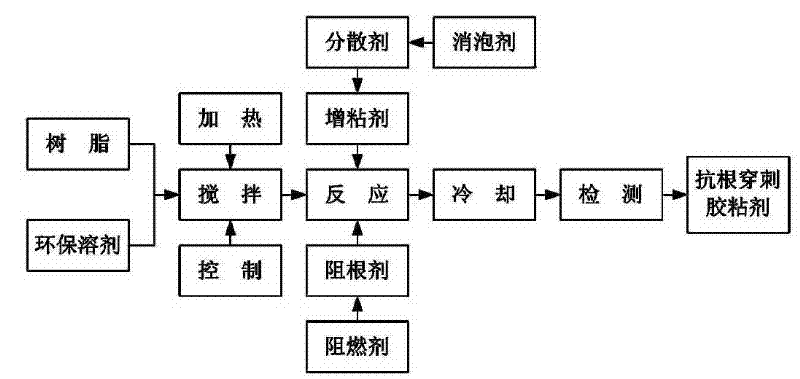

[0041] Embodiment 1, according to figure 1 Shown production process flow, prepare the anti-plant root puncture adhesive of the present invention.

[0042] (1) The raw material formula is as follows by weight:

[0043] 20.0 parts of SBS resin; 20.0 parts of petroleum resin; 50.0 parts of solvent oil; 5.0 parts of ethyl acetate; 1.5 parts of terpene resin; 0.5 parts of gum rosin; 0.5 parts of foaming agent; 1.0 parts of aluminum hydroxide; 4.0 parts of antimony trioxide;

[0044] (2) The preparation method of the adhesive is as follows:

[0045] In a container equipped with a stirrer, a thermometer, a feeding device and an automatic temperature controller, add SBS resin, petroleum resin, solvent naphtha and ethyl acetate weighed according to the formula, turn on the mixer and temperature controller, start stirring and heat up to 85 Melt all the resin at -90°C, then add terpene resin, gum rosin, anti-aging agent 264, root inhibitor, dispersant, defoamer, aluminum hydroxide and...

Embodiment 2

[0047] (1) The raw material formula is as follows by weight:

[0048] 25.0 parts of SBS resin; 15.0 parts of petroleum resin; 25.0 parts of dichloropropane; 30.0 parts of solvent oil; 2.2 parts of terpene resin; 0.8 part of gum rosin; 0.5 parts of foaming agent; 0.5 parts of aluminum hydroxide; 3.5 parts of antimony trioxide;

[0049] (2) The preparation method of the adhesive is as follows:

[0050] In the container equipped with stirrer, thermometer, feeding device and automatic temperature controller, add SBS resin, petroleum resin, solvent naphtha and dichloropropane weighed according to the formula, turn on the mixer and temperature controller, start stirring and heat up to 85 Melt all the resin at -90°C, then add terpene resin, gum rosin, anti-aging agent 264, root inhibitor, dispersant, defoamer, aluminum hydroxide and antimony trioxide, and continue heating for 1.5-2.0 hours , turn off the temperature controller, drop the temperature to room temperature, and put it i...

Embodiment 3

[0052] (1) The raw material formula is as follows by weight:

[0053] 15.0 parts of SBS resin; 20.0 parts of petroleum resin; 25.0 parts of dichloropropane; 35.0 parts of ethyl acetate; 1.0 parts of terpene resin; 0.3 part of gum rosin; 1.0 part of antioxidant 264; 1.0 parts of defoamer; 0.7 parts of aluminum hydroxide; 4.0 parts of antimony trioxide;

[0054] (2) The preparation method of the adhesive is as follows:

[0055] In the container equipped with agitator, thermometer, feeding device and automatic temperature controller, add SBS resin, petroleum resin, ethyl acetate and dichloropropane weighed according to the formula, turn on the agitator and temperature controller, start stirring and heat up to 85-90°C, melt all the resin, then add terpene resin, gum rosin, anti-aging agent 264, root inhibitor, dispersant, defoamer, aluminum hydroxide and antimony trioxide, and continue heating for 1.5-2.0 Hours, turn off the temperature controller, the temperature drops to room ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com