Integrated efficient turbine with air outlet constraint structure

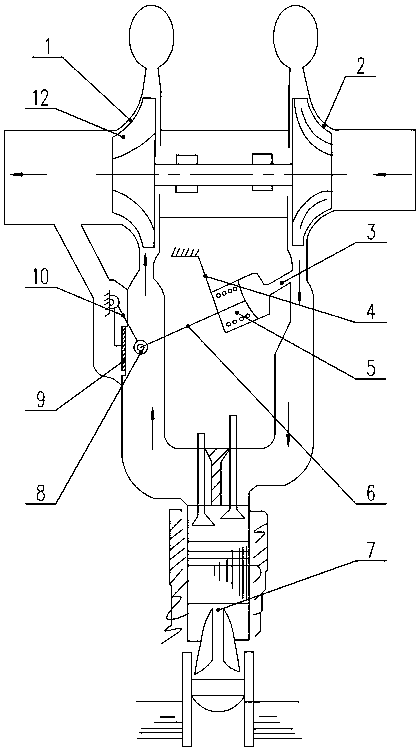

A constrained structure, integrated technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as failure to achieve optimal performance, large differences in resistance of post-processing systems, and improve turbine efficiency and airflow. Loss reduction and efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

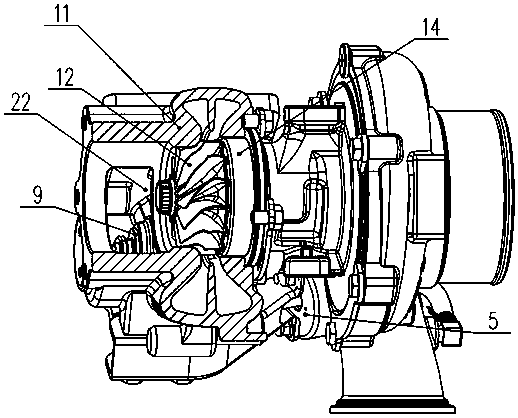

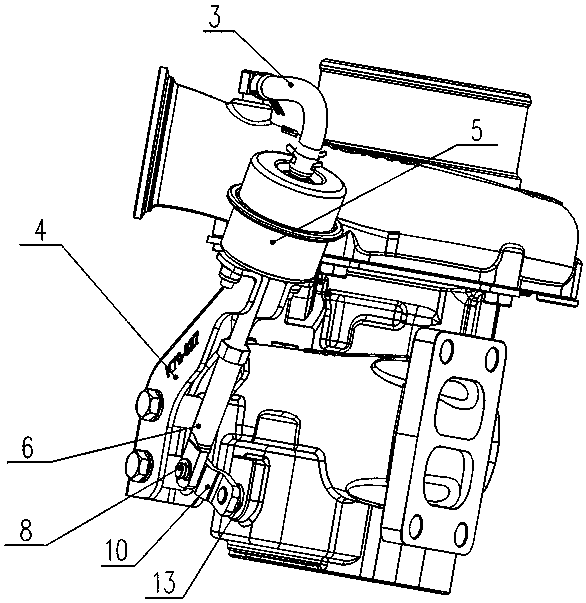

[0038] Such as Figure 4 , Figure 5 and Figure 6 Commonly shown, the integrated high-efficiency turbine with an air outlet restriction structure includes a turbine casing 11 and a turbine casing cover plate 16 installed at the end of the turbine casing 11. A turbine 12 and an air outlet guide groove 18 are installed in the turbine casing 11. The turbine casing 11 is provided with a turbine casing bypass exhaust passage 21 and a turbine exhaust gas passage 22 , and the turbine casing bypass exhaust passage 21 and the turbine exhaust gas passage 22 extend from the turbine casing 11 to the turbine casing cover plate 16 . The turbine casing bypass exhaust passage 21 and the turbine exhaust passage 22 guide the airflow separately, and the two do not directly communicate with each other. Both the turbine casing bypass exhaust passage 21 and the turbine exhaust passage 22 are tapered. The side wall of the turbine casing cover plate 18 is provided with a bypass guide hole 20 comm...

Embodiment 2

[0050] like Figure 7 and Figure 8 Commonly shown, the integrated high-efficiency turbine with an air outlet restriction structure includes a turbine casing 11 and a turbine casing cover plate 16 installed at the end of the turbine casing 11. A turbine 12 and an air outlet guide groove 18 are installed in the turbine casing 11. The turbine casing 11 is provided with a turbine casing bypass exhaust passage 21 and a turbine exhaust gas passage 22 , and the turbine casing bypass exhaust passage 21 and the turbine exhaust gas passage 22 extend from the turbine casing 11 to the turbine casing cover plate 16 . The turbine casing bypass exhaust passage 21 and the turbine exhaust passage 22 guide the airflow separately, and the two do not directly communicate with each other. Both the turbine casing bypass exhaust passage 21 and the turbine exhaust passage 22 are tapered. The side wall of the turbine casing cover plate 18 is provided with a bypass guide hole 20 communicating with t...

Embodiment 3

[0055] like Figure 9 and Figure 10 Commonly shown, the integrated high-efficiency turbine with an air outlet restriction structure includes a turbine casing 11 and a turbine casing cover plate 16 installed at the end of the turbine casing 11. A turbine 12 and an air outlet guide groove 18 are installed in the turbine casing 11. The turbine casing 11 is provided with a turbine casing bypass exhaust passage 21 and a turbine exhaust gas passage 22 , and the turbine casing bypass exhaust passage 21 and the turbine exhaust gas passage 22 extend from the turbine casing 11 to the turbine casing cover plate 16 . The turbine casing bypass exhaust passage 21 and the turbine exhaust passage 22 guide the airflow separately, and the two do not directly communicate with each other. Both the turbine casing bypass exhaust passage 21 and the turbine exhaust passage 22 are tapered. The side wall of the turbine casing cover plate 18 is provided with a bypass guide hole 20 communicating with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com