High back pressure heat supply unit safety control method

A heat supply unit and safety control technology, applied in heating methods, control systems, household heating, etc., can solve problems such as limited steam extraction and inability to solve steam turbine tripping, achieve reasonable safety control methods, avoid overheating damage, and ensure The effect of device security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with accompanying drawing and specific embodiment, the content of the present invention is described in further detail:

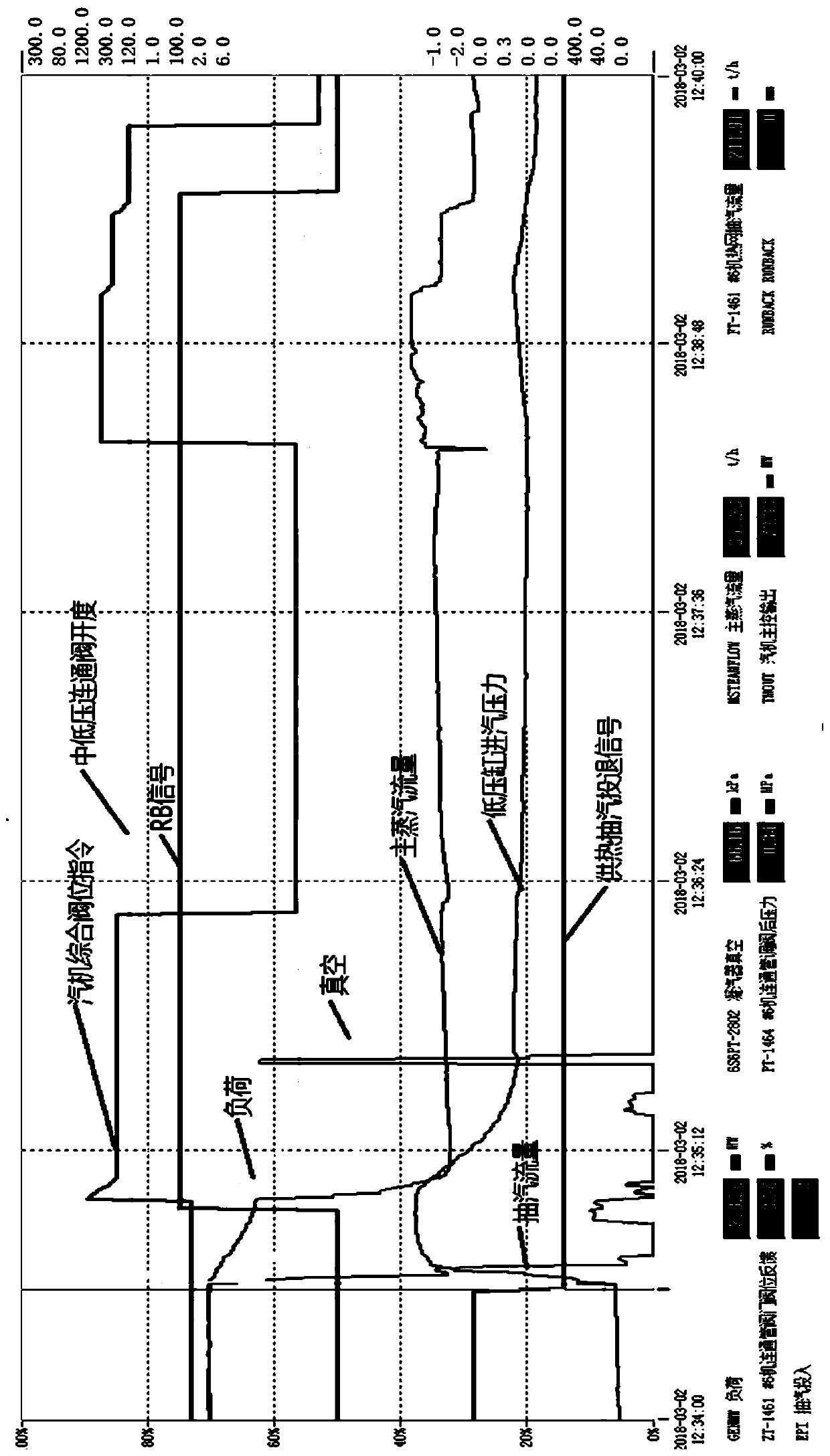

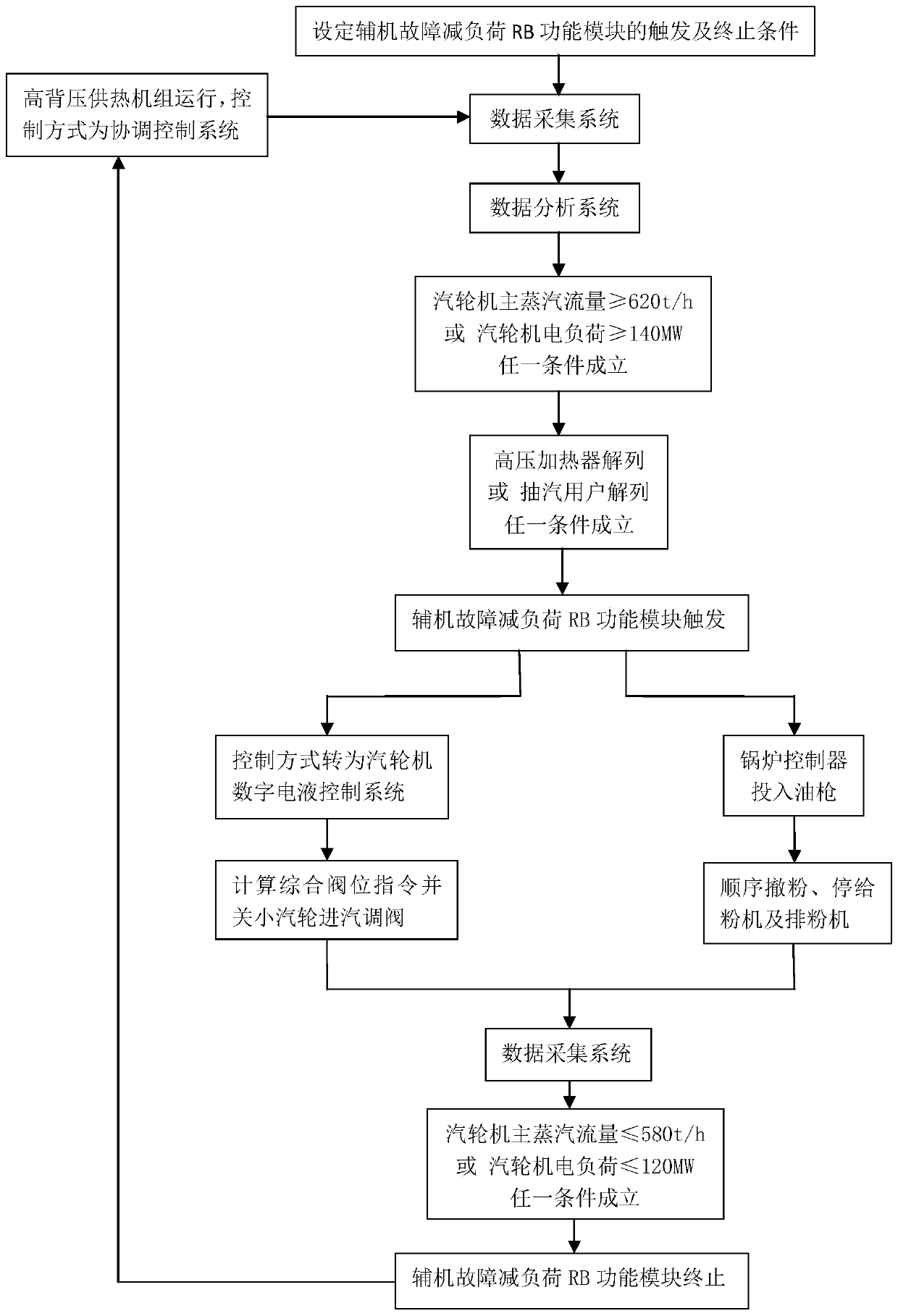

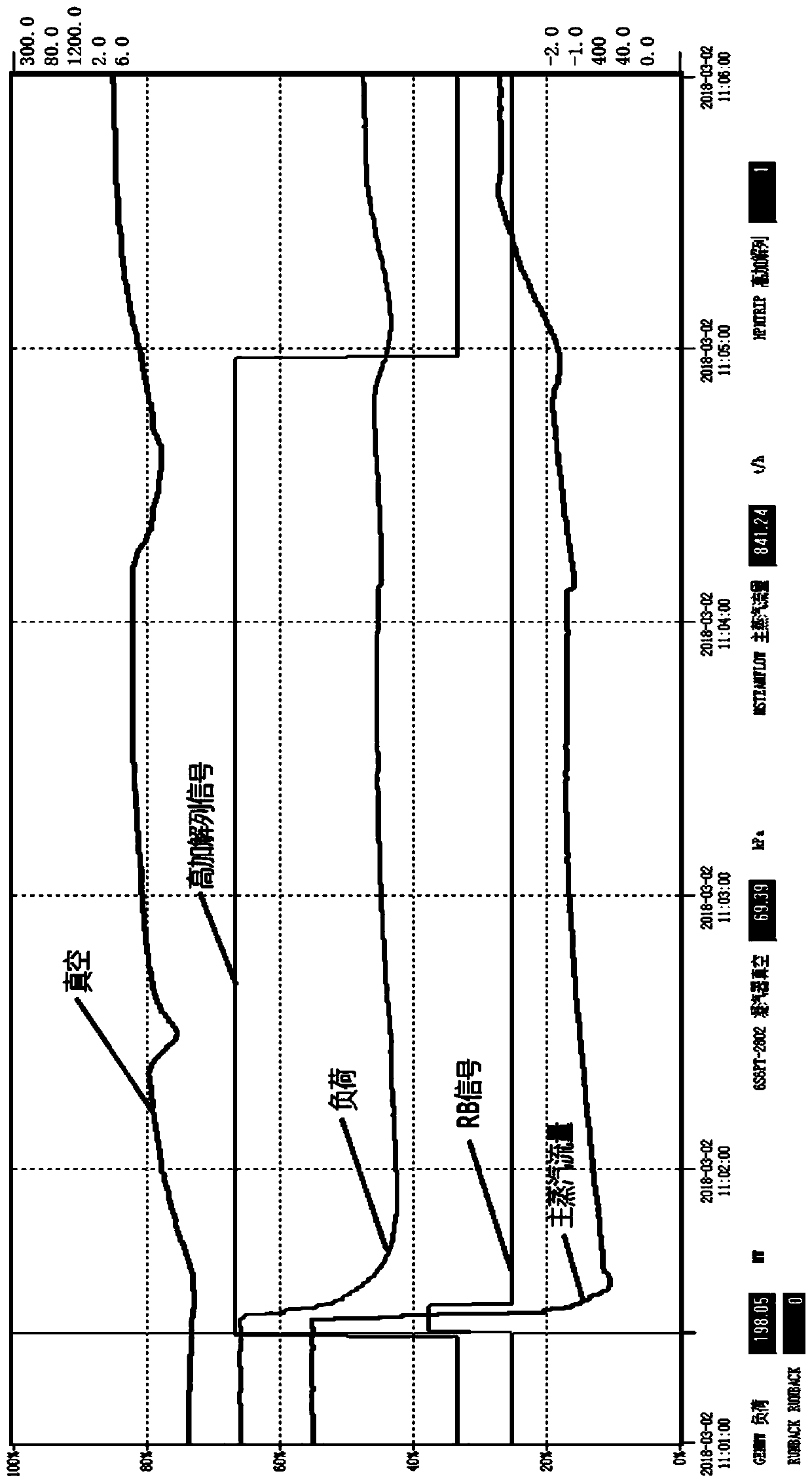

[0052] The safety control method of the high back pressure heating unit is based on the data analysis system in the distributed control system DCS of the power plant, the RB function module for auxiliary failure load reduction, the data acquisition system DAS, the machine-furnace coordinated control system CCS, and the steam turbine digital electro-hydraulic control system. Control systems or hardware such as DEH, boiler control system and other control systems or hardware are configured with logic settings, and the hardware system is operated through specific program instructions to reduce the amount of main steam entering the steam turbine, and then control the electrical load and the heat load of the steam inlet condenser to reduce the The exhaust back pressure of the steam turbine increases the vacuum of the condenser, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com