Linear motion bearing assembly

A linear motion bearing, linear bearing technology, applied in the direction of linear motion bearings, bearing components, bearings, etc., can solve the problems of easy adhesion of dust or chips, shortened service life, linear bearing wear, etc., to reduce wear and strain, Improves straightness and load-carrying capacity, and contributes to smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

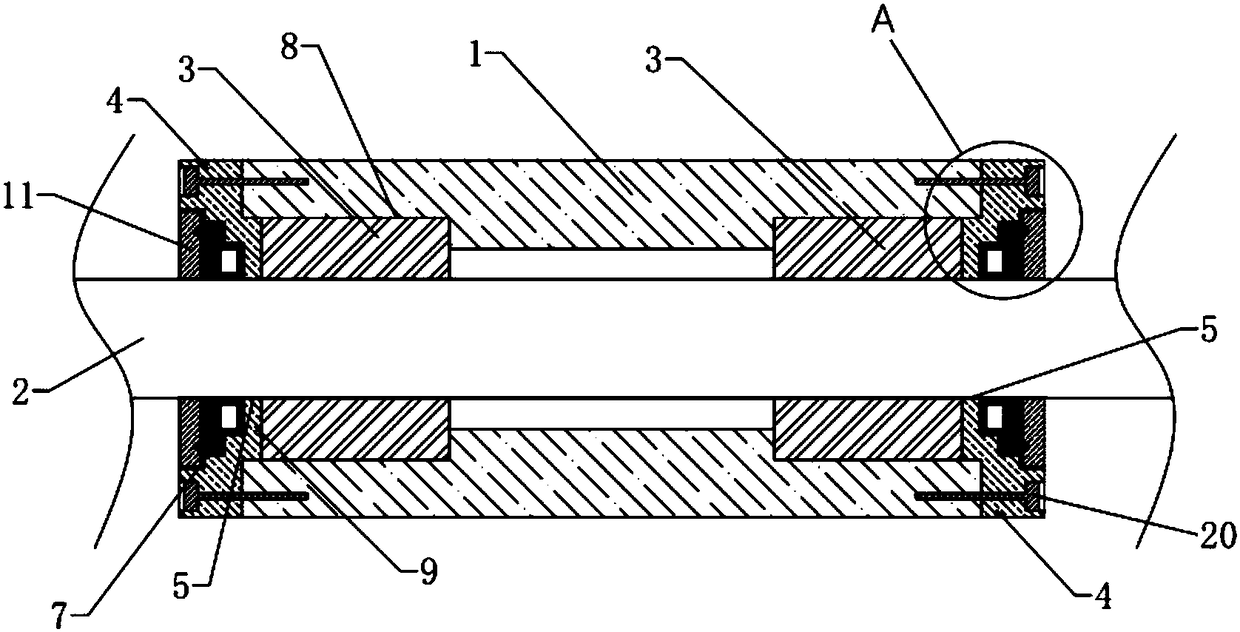

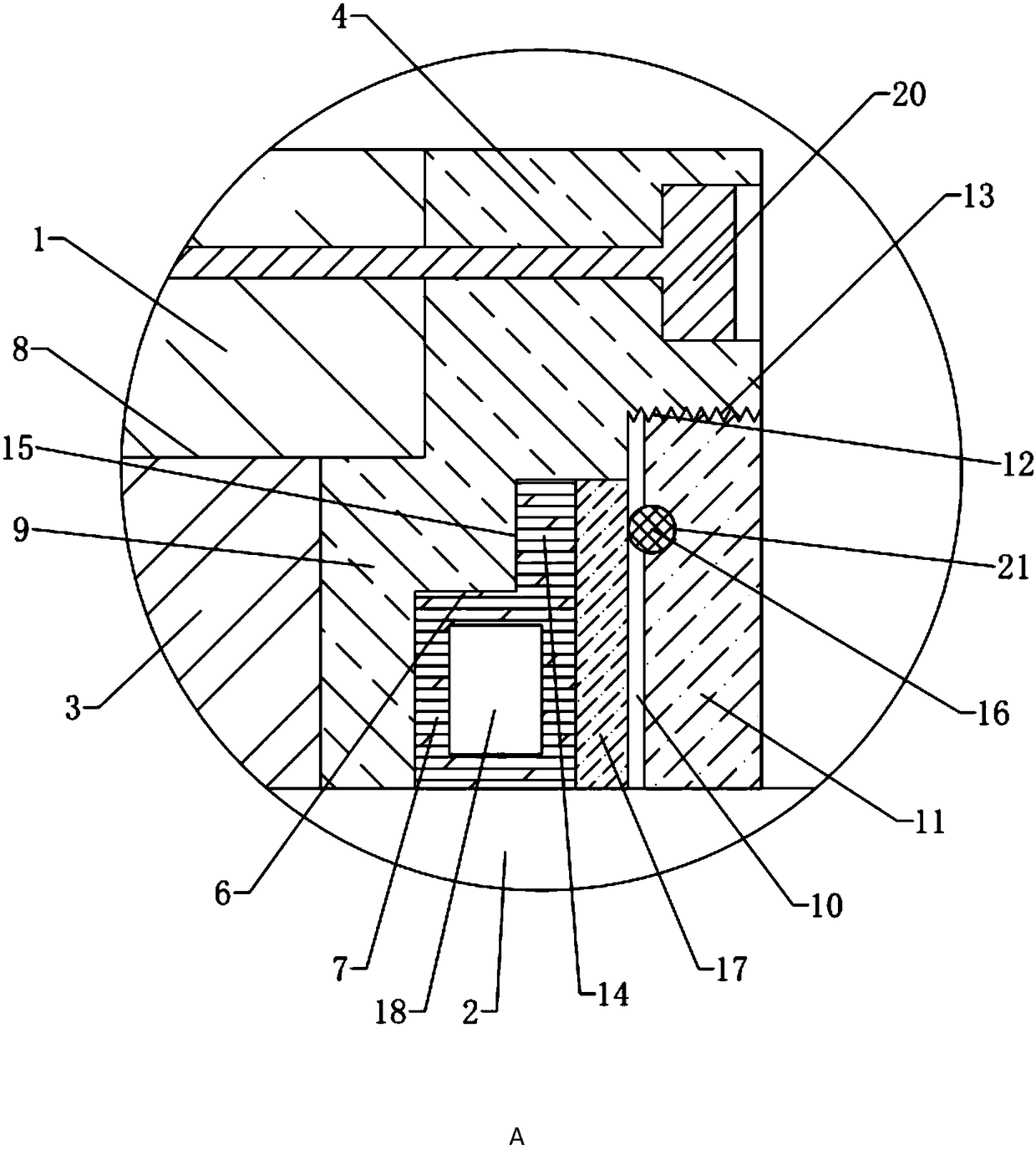

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

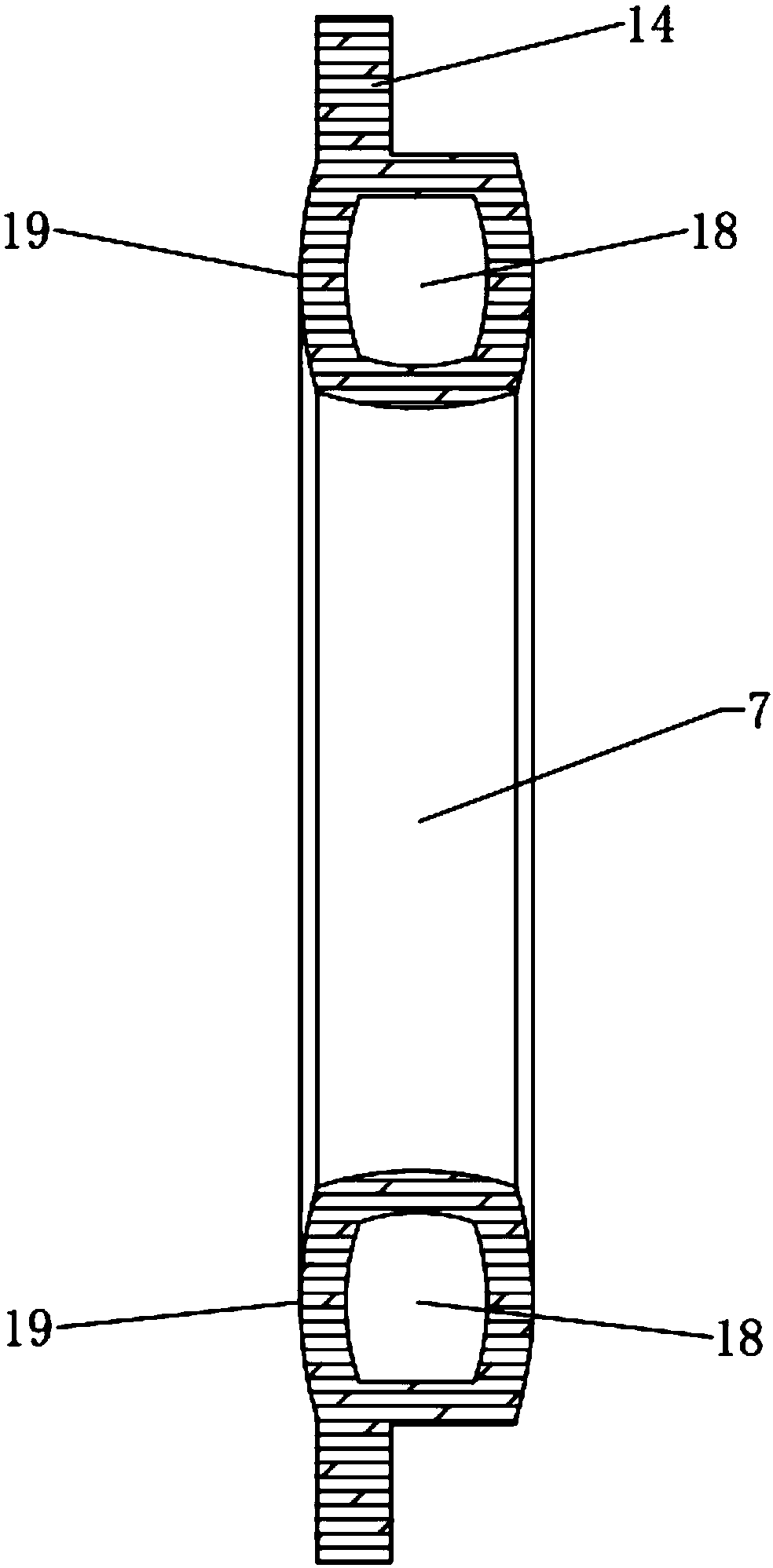

[0033] A linear motion bearing assembly disclosed in this embodiment, such as figure 1 and figure 2 As shown, it includes a cylindrical bearing seat 1, the inner cavity of the bearing seat 1 is provided with linear bearings 3 for the drive shaft 2 to pass through in turn at the inner cavity of the bearing seat 1, and the end surface of the bearing seat 1 is provided with linear bearings for 3 snap-in stepped ring groove 8. That is, there are two stepped ring grooves 8, which are respectively symmetrically opened on the two end faces of the bearing housing 1, and the central axis of each stepped annular groove 8 coincides with the central axis of the bearing housing 1; the linear bearing 3 is also provided with two , the two linear bearings 3 are respectively inserted into the two stepped ring grooves 8, so that the two linear bearings 3 can be kept on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com