Waveguide grating filter and manufacturing method thereof

A technology of a waveguide grating and a manufacturing method, which is applied to optical waveguides, instruments, optics, etc., can solve problems such as reducing the stability of mechanical mechanisms, low tuning efficiency, and increasing response time, achieving good mechanical stability and realizing wavelength selection. , the effect of increasing the response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

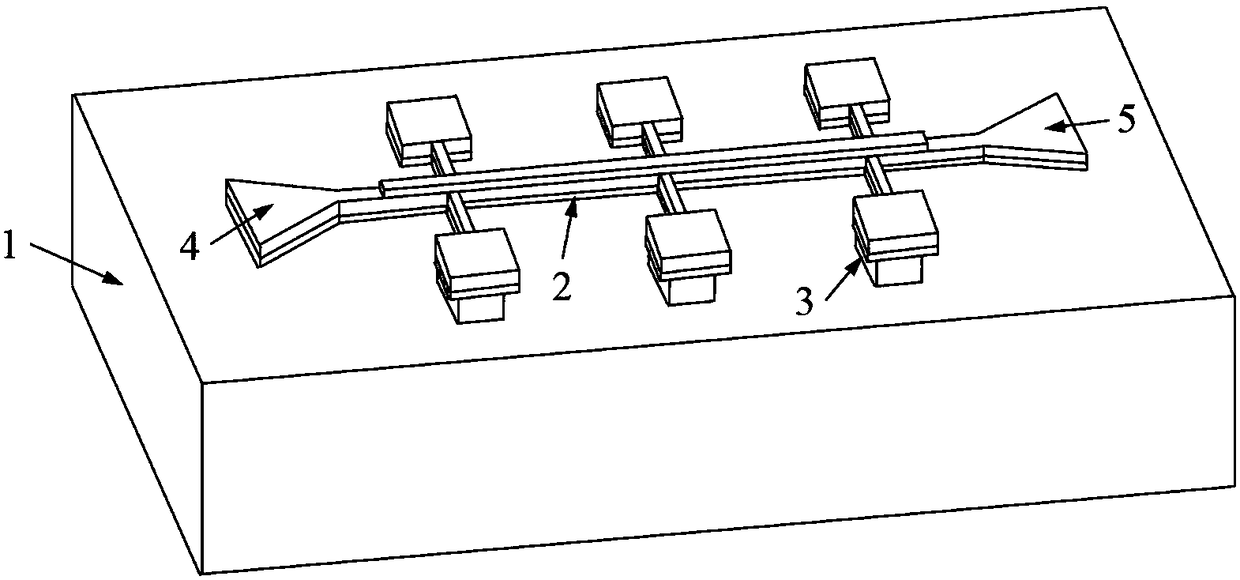

[0047] Constructed as figure 1 The waveguide grating filter shown.

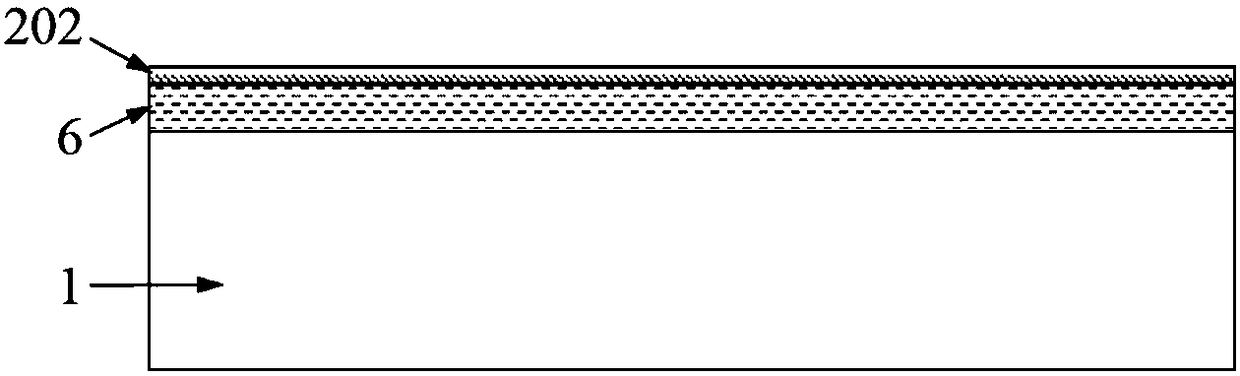

[0048] Using a section structure such as figure 2 The SOI wafer shown has a silicon material substrate 1 , an intermediate layer of silicon dioxide 6 and a top layer of silicon 202 .

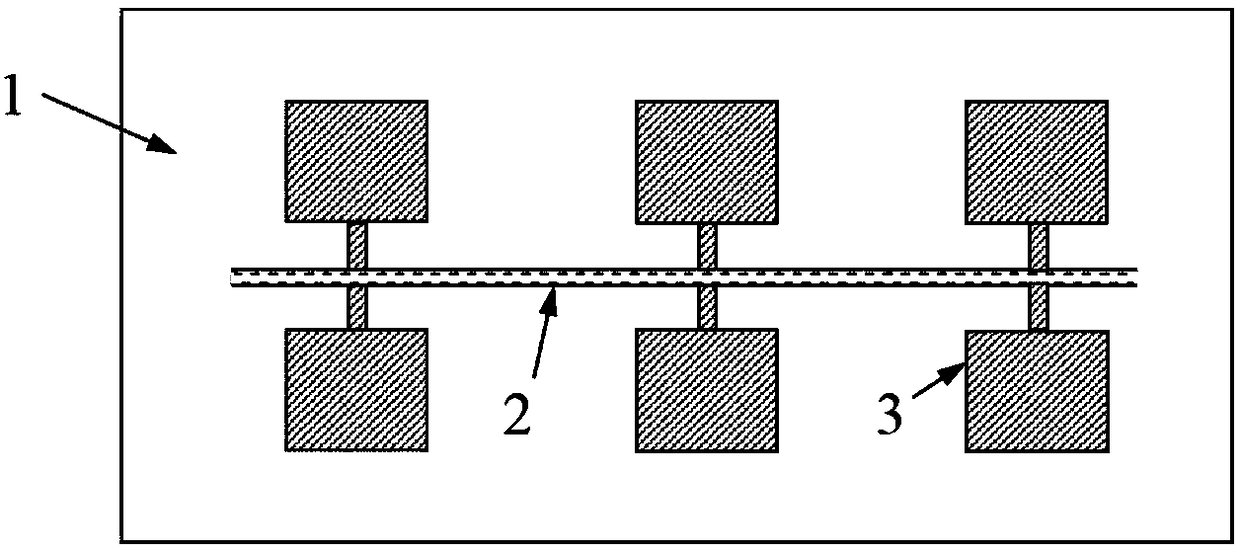

[0049] Spin-coat photoresist on the top silicon of the SOI wafer, and use this as a mask to etch to obtain the waveguide 2 and the beam-column structures 3 arranged periodically on both sides of the waveguide. The top view structure is as follows image 3 shown. Then, for the SOI wafer with the above structure, use hydrofluoric acid (HF) wet etching to remove the silicon dioxide layer under the ridge waveguide, and keep part of the silicon dioxide as the pillar 302a, to obtain the following: Figure 4 The structure shown with an air gap, also constitutes a beam-column structure.

[0050] The waveguide body 202, the optical input end 4 and the optical input end 5 are all coupler structures fabricated on the top silicon layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com