Belt conveyor low frequency direct drive middle-high voltage frequency convertor

A medium and high voltage frequency converter, belt conveyor technology, applied in the direction of controlling electromechanical brakes, converting AC power input to AC power output, controlling generators, etc., can solve the problem of increasing investment costs, increasing the overall volume and weight of equipment, and energy consumption. Improve and other issues, to reduce the overall volume and cost, social and economic benefits are significant, to meet the effect of smooth speed regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

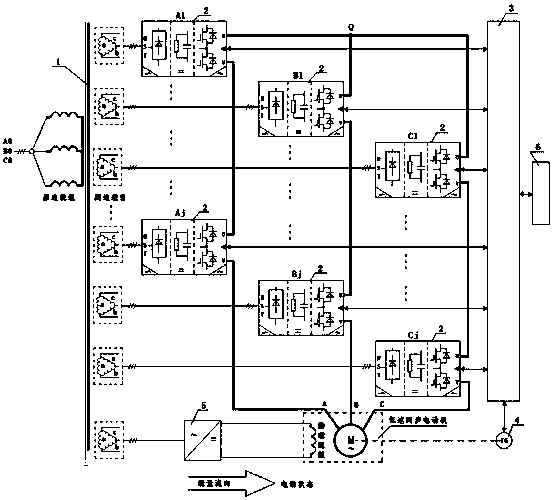

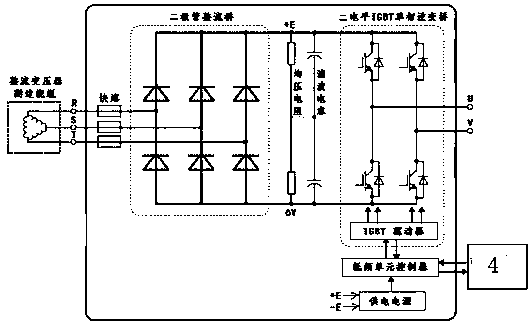

[0039] Example as figure 1 Shown and combined image 3 , Figure 4 with Figure 5 , The low-frequency direct-drive medium and high-voltage frequency converter of the belt conveyor drives a separately excited low-speed synchronous machine. For example, the rated voltage of the power supply grid is 10kV, the rated power of the low-speed synchronous machine is 1000kW, the voltage is 6kV, the excitation rectifier transformer is separately provided, and the overload multiple of the rectifier transformer is 1.3 times. The low-frequency direct drive medium-high voltage frequency conversion of the belt conveyor is required The overload multiple of the converter is greater than 2.0 times, and the power factor is calculated as 1.0; Selection: The primary input voltage, rated power, and number of secondary windings of the rectifier transformer are: 10kV, 1560kVA (> 2.0*1000 / 1.3=1538kW) and 15 units (see Table 1). The two-quadrant low-frequency power unit is designed according to the low-fre...

Embodiment 2

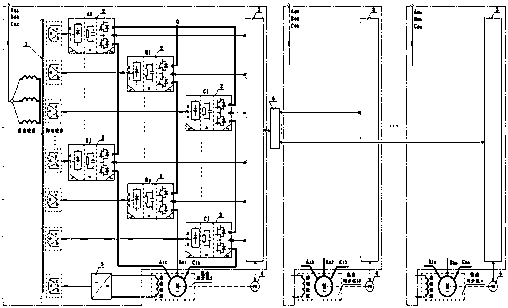

[0040] Example two figure 2 Shown and combined image 3 , Figure 4 with Figure 5 , According to the master-slave structure, the multiple sets of low-frequency direct-drive medium and high-voltage inverters of the belt conveyor drive multiple low-speed AC motors of the same belt conveyor, one of which is the master and the others are the slaves; The host and slave respectively form a network communication system with the PLC in the conveyor control system 6. The said PLC can define the host and the slave arbitrarily and transform according to practical needs, including the realization of the emergency that allows any single machine to be offline Running, the host has a complete closed loop of speed, current and voltage and transmits the data output by the speed loop to the PLC in real time. The slave and the host share a speed loop and obtain the data output by the speed loop from the PLC in real time as the slave The given signal of torque and current of the machine.

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com