Low frequency direct drive middle-high voltage inverter of mine hoist

A technology of medium and high voltage inverters and mine hoists, which is applied in the control of electromechanical brakes, generators, motor generators, etc., which can solve the problems of increased investment costs, unguaranteed pass rate, and increased energy consumption, so as to reduce the overall The size and cost, social and economic benefits are remarkable, and the effect of smooth speed regulation can be satisfied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

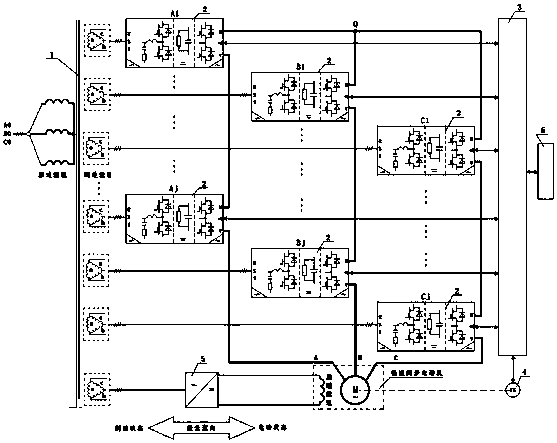

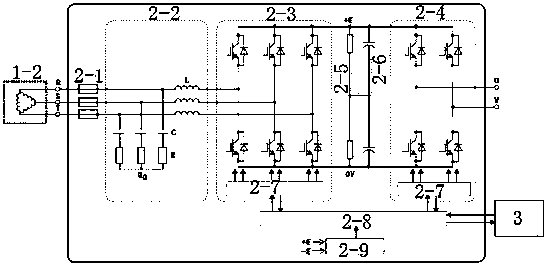

[0032] Such as figure 1 As shown, a mine hoist low frequency direct drive medium and high voltage frequency converter, the low frequency direct drive medium and high voltage frequency converter has a rectifier transformer 1 to provide voltage for it; the rectifier transformer 1 has a set of primary windings 1-1 and 3 *j sets of secondary windings 1-2, j=1, 2...; 3*j sets of secondary windings 1-2 are in-phase windings; each set of secondary windings is connected in series with a four-quadrant low-frequency power unit 2 The stable output frequency range of the four-quadrant low-frequency power unit 2 is 0.1Hz~17.0Hz; the number of the four-quadrant low-frequency power unit 2 corresponds to the secondary winding 1-2, at least 3*1, and forms A , B, C three-phase; combined image 3 , Figure 4 , the four-quadrant low-frequency power unit 2 has a two-level IGBT three-phase rectifier bridge 2-3 and a two-level IGBT-H type inverter bridge 2-4 installed on the same radiator element ...

Embodiment 2

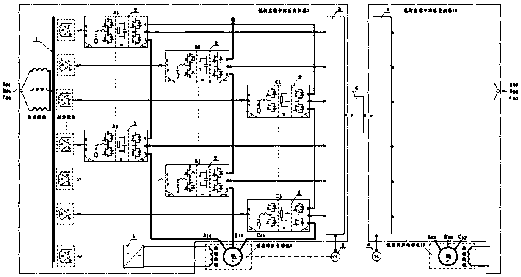

[0037] Embodiment two: if figure 2 shown, combined with image 3 and Figure 4 , the main structure of this embodiment is the same as that of Embodiment 1. In this embodiment, there are two sets of low-frequency direct-drive medium-high voltage inverters, and the three-phase A, B, and C phases of the two sets of low-frequency direct-drive medium-high voltage inverters The outputs are all connected to the corresponding low-speed synchronous motor stator windings, and the two sets of low-frequency direct drive medium and high voltage frequency converters are connected to the hoist control system 6; the two sets of mine hoist low frequency direct drive medium and high voltage The frequency converter drives two low-speed AC motors of the same mine hoist respectively according to the master-slave structure. The master and the slave respectively form a network communication system with the PLC in the hoist control system 6. The PLC can arbitrarily define the master and The slave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com