Self-rotation angle tool

A self-rotating and tooling technology, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problems of high cost and difficult angle adjustment, and achieve the effect of simple structure, simple and convenient operation process, and material cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

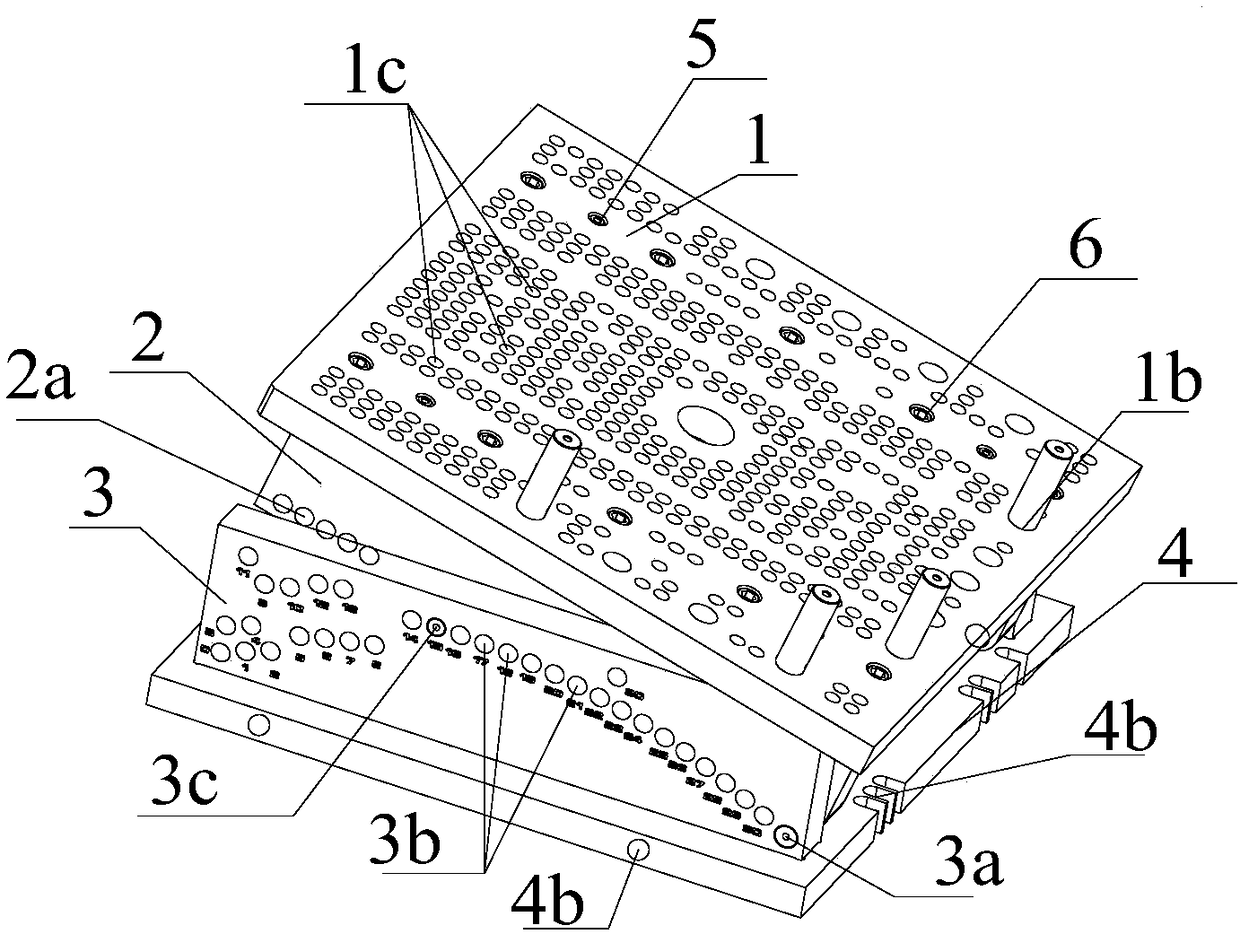

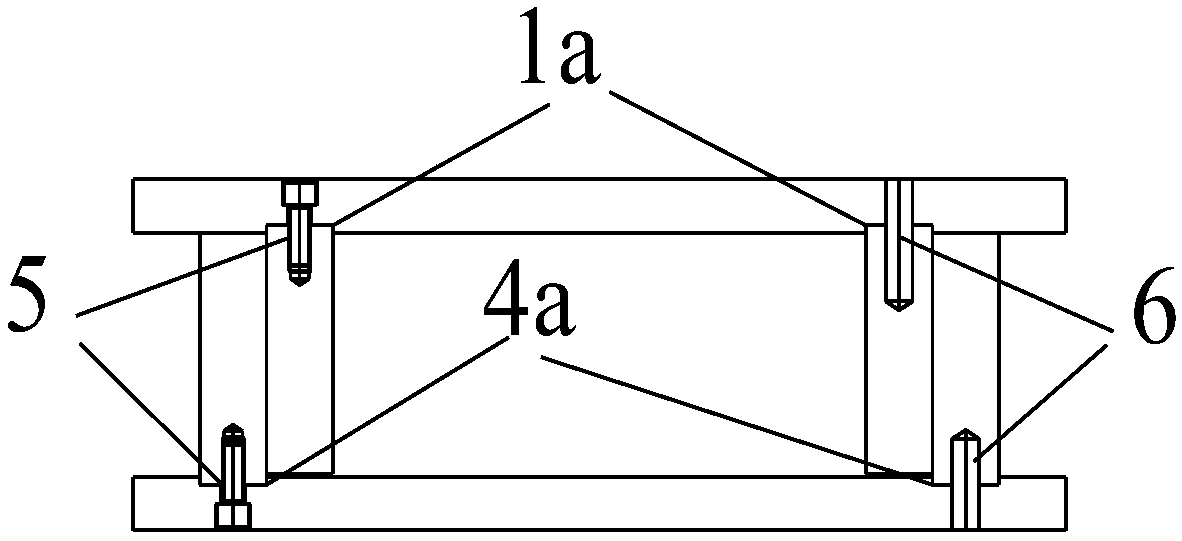

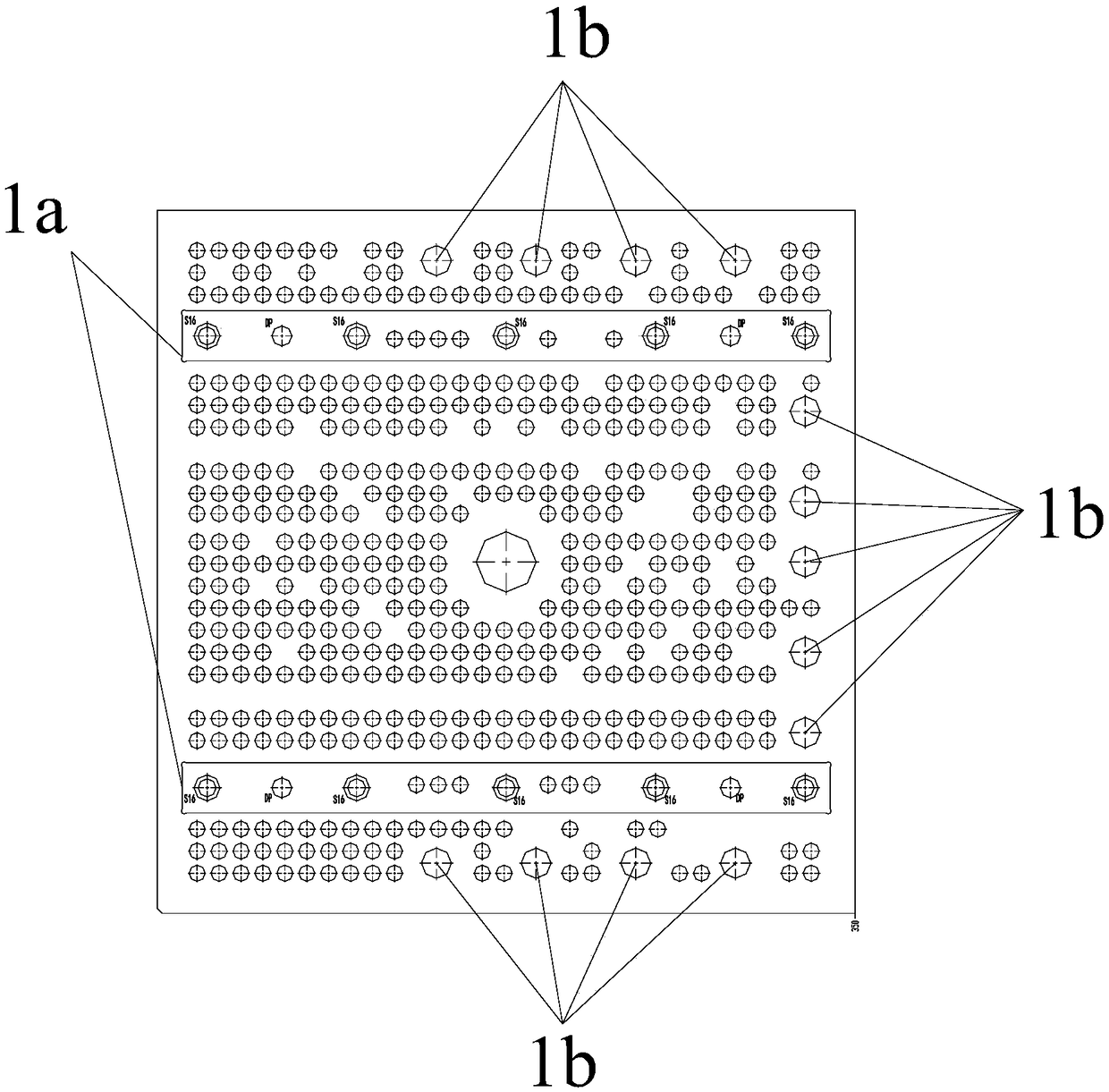

[0027] like Figure 1-6 , a self-rotating angle tooling, comprising an upper tooling assembly and a lower tooling assembly, the upper tooling assembly includes a bearing panel 1 for clamping workpieces, the lower tooling assembly is fixed along the horizontal direction, and the end of the upper tooling assembly is hinged to the lower tooling assembly , the lower tooling assembly is provided with several angle pin holes 3b, and the upper tooling assembly is provided with equidistant pin holes 2a aligned with one of the angle pin holes 3b when the bearing panel 1 rotates to a certain angle, and the angle pin holes 3b and A positioning piece is provided between the equidistant pin holes 2a to fix the relative positions of the upper tooling assembly and the lower tooling assembly. In this embodiment, the positioning member is the fixing pin 3c passing through the equidistant pin holes 2a and the angle pin holes 3b at the same time, and positioning blocks can also be used for posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com