Deep land-filling area gravity type retaining wall and reinforced soil retaining wall combined supporting structure

A support structure and gravity technology, applied in the field of geotechnical engineering, can solve the problems of low support height, high cost, large amount of engineering, etc., and achieve the effects of convenient construction, good environmental and economic benefits, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

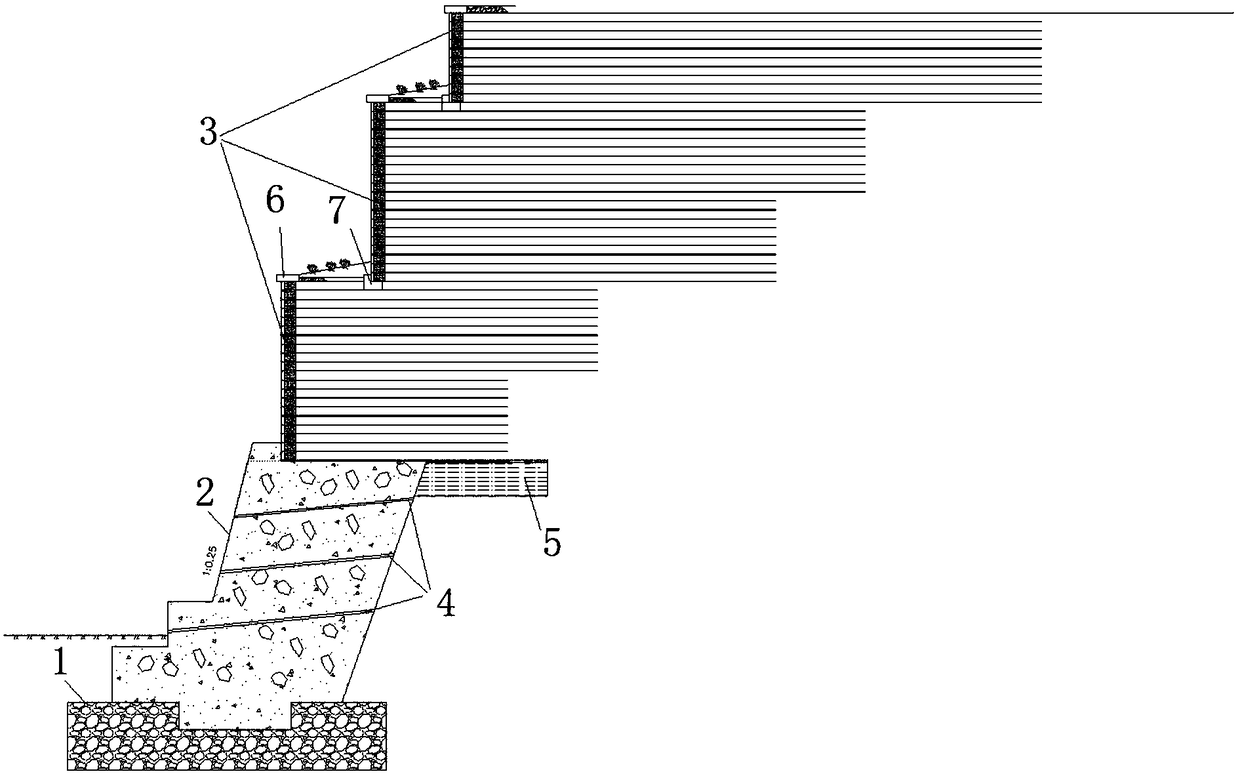

[0034] Such as figure 1 with figure 2 As shown, the backfill thickness of a certain project fill slope is 28m, the top of the slope is arranged with buildings, the foot of the slope is a natural gully with perennial water flow, the stratum is silty clay, and the characteristic value of the bearing capacity of the foundation is 290kPa.

[0035] The thickness of sand and gravel cushion layer 1 foundation treatment is 3m, and the width is 14.3m. The choice of sand and gravel materials should achieve reasonable gradation, and the content of fine grains should be controlled at 25% to 35%. The thickness of the single layer of sand and gravel cushion is 40cm, and the water content is controlled between 3% and 6%. During the construction, the surface is flattened by flat rolling once, and then vibrating and rolled six times. Compaction coefficient ≥ 0.97, foundation bearing capacity ≥ 450kPa.

[0036] Gravity retaining wall 2 is a 10.8m-high rubble concrete retaining wall, includi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com