Pressure crack network design and completion method for enhanced geothermal system

A fracturing, enhanced technology, applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve problems such as low feasibility and efficiency, and achieve reduced production costs, large heat utilization, and efficient water flow channels Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] An enhanced hydrothermal geothermal system well completion method, the specific steps are as follows:

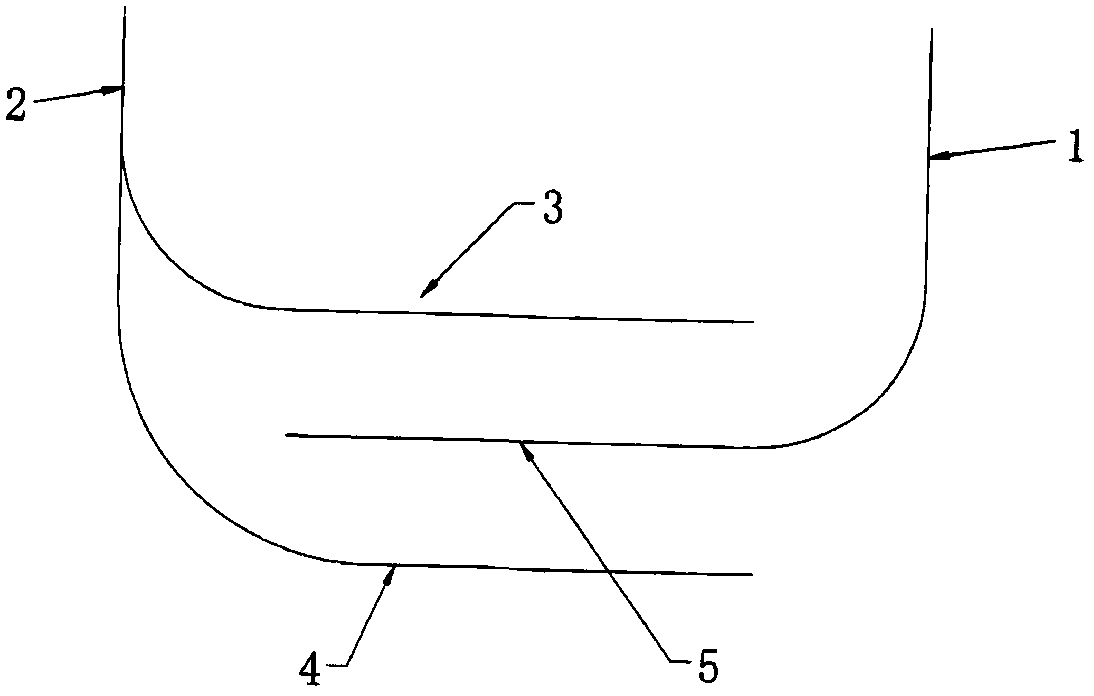

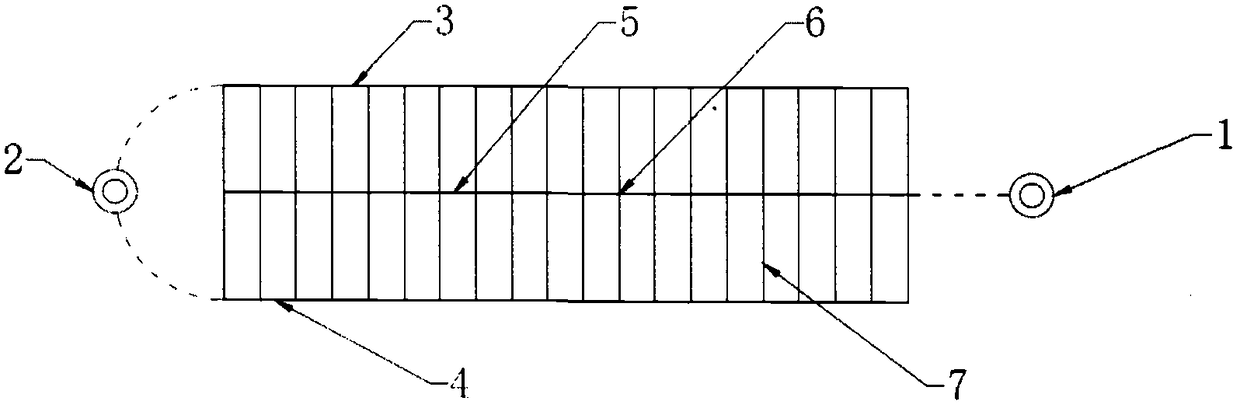

[0022] (1) Select the hot dry rock reservoir, and select two points A and B with a distance of 2000m on the ground as the wellhead positions of the water injection well (1) and the water production well (2), respectively. First, drill a water injection well at point A, inject The well type of the water well is a horizontal well, and the length of the horizontal well section of the water injection well in the geothermal reservoir is 2000m; using conventional drilling equipment, the depth of the vertical well section is designed according to the actual depth of the dry hot rock reservoir, and the vertical section of the horizontal well is drilled to reach the hot dry rock reservoir. After the horizontal section (5) of the water injection well is drilled with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com