High-power steam motor for catapult-assisted takeoff of carrier-based aircraft

A steam motor, high-power technology, applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problems of low power of pneumatic vane motors and no high-power vane motors that can directly use steam, etc., to achieve safe and reliable work, The effect of low cost, wide power range and speed range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

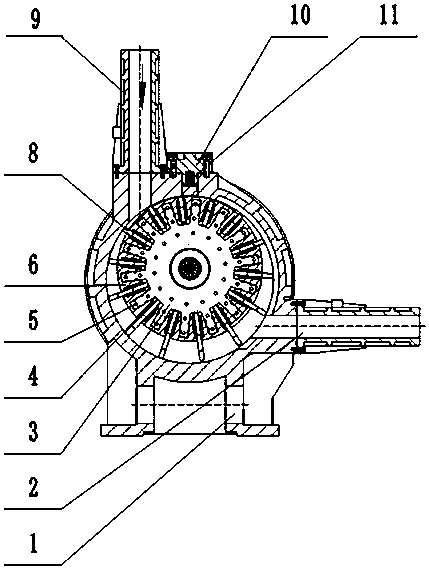

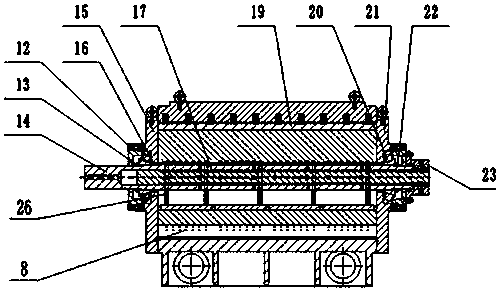

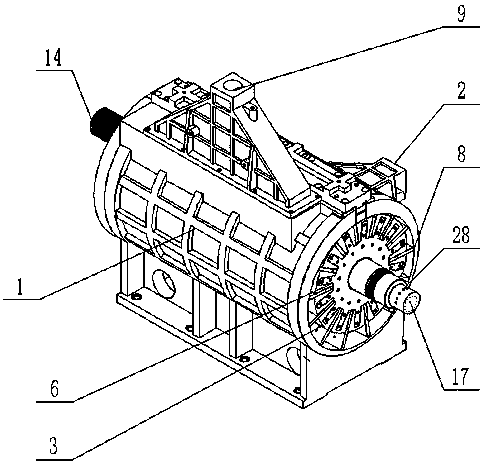

[0032] A high-power steam motor for ejection and take-off of a carrier-based aircraft includes a motor casing 1, and left and right end covers 15 and 21 are respectively fixedly installed on the left and right sides of the motor casing 1. Inside the motor casing 1 are A cylindrical accommodating cavity, a steam inlet 9 is fixedly installed on the motor housing 1, a steam exhaust port 2 is fixedly installed on the side, and the steam inlet 9 and the steam exhaust port 2 are both connected with the accommodating cavity. A transmission shaft 14 is arranged in the cavity, and the transmission shaft 14 is offset from the center of the accommodation cavity and is rotatably arranged in the accommodation cavity. The transmission shaft 14 is provided with a toothed spline. A support frame 3 is installed at the spline part. The support frame 3 is fixedly connected to the toothed rotor 6 through the pin shaft 5. The two adjacent teeth of the toothed rotor 6 form a through groove, and an o...

Embodiment 2

[0043] Further, the number of the blades 8 is an even number, and the two opposite blades are rigidly connected by the blade connecting rod 7. The toothed rotor and the transmission shaft 14 are provided with ventilation holes 26 corresponding to the ventilation grooves 25 and fixed fan blades. The blade through hole 27 is on the same line as the ventilation hole 26, the fan blade can slide up and down through the blade through hole, and the connecting rod is increased to increase the stability of the blade.

[0044] The power of the motor in the present invention is provided by steam and the power is large, so it is called a high-power steam motor. In order to reduce the manufacturing difficulty of the rotor, a split rotor structure is designed; in order to reduce the overall quality of the rotating parts, a low-density rotor is designed; in order to ensure reliable output of high-power torque, a split-type rotor is designed to be embedded into a high-strength rotor through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com