A filter cartridge dust removal and cleaning device

A cleaning device and filter cartridge technology, applied in the direction of filtration and separation, filter regeneration, separation methods, etc., can solve the problems of affecting the effect and efficiency of dust removal and cleaning, the outer surface of the filter cartridge cannot be cleaned, and the use of large limitations, etc., to achieve Improve dust removal strength, promote flushing, and comprehensive effect of dust removal and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

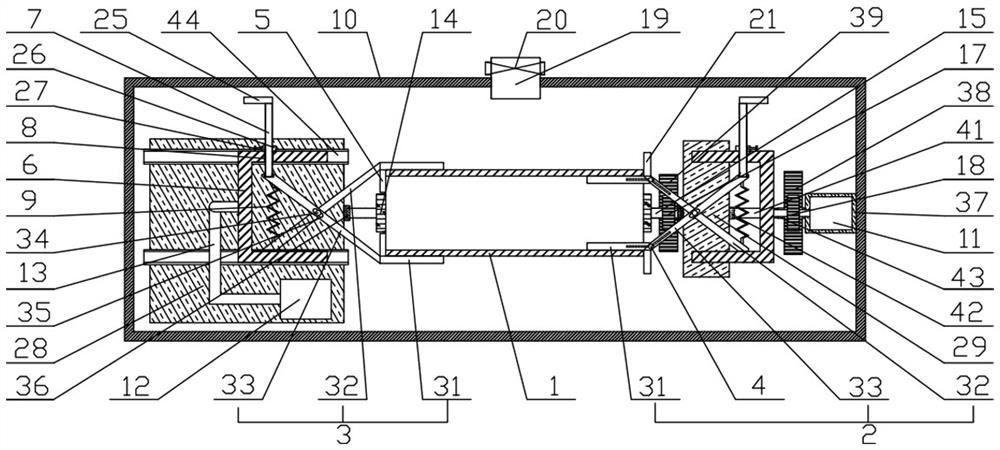

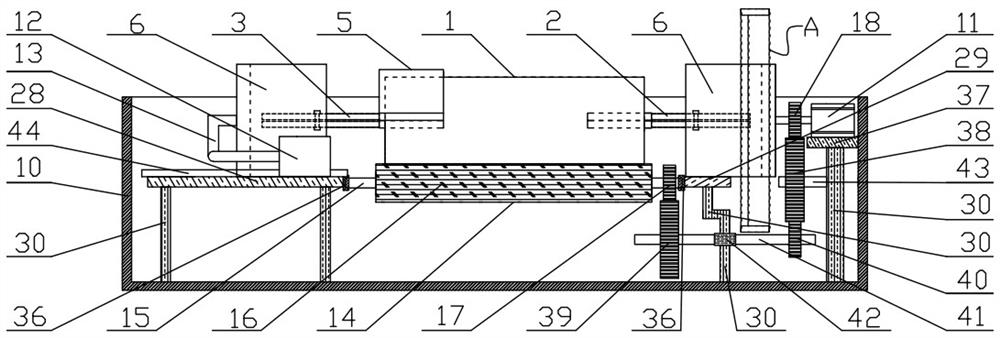

[0036] like figure 1 and figure 2 A filter cartridge dust removal and cleaning device shown includes a cleaning pool 10 and a clamping mechanism, a driving mechanism and a rotating brush mechanism arranged in the cleaning pool 10,

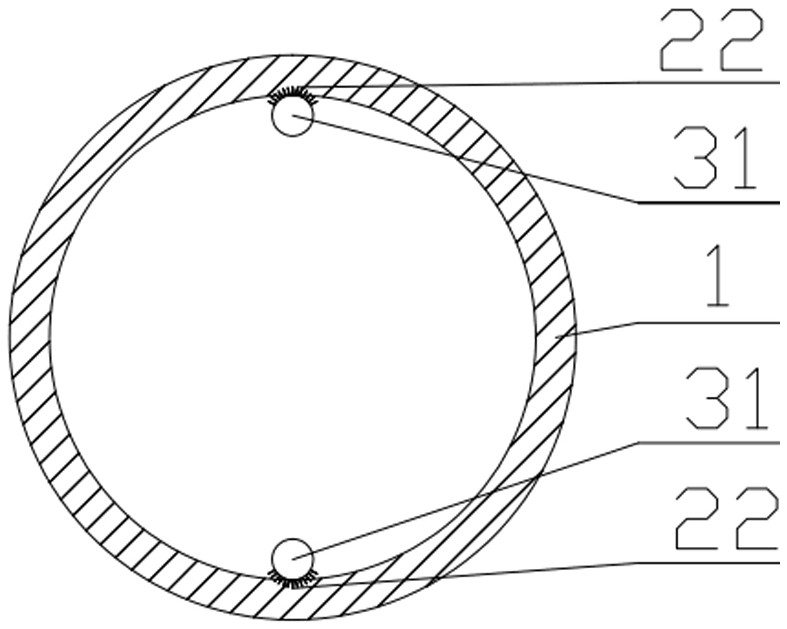

[0037] The clamping mechanism includes an inner clamp 2 and an outer clamp 3 acting on the inner surface and the outer surface of the filter cartridge 1 respectively, the inner clamp 2 and the outer clamp 3 are arranged oppositely, and the inner clamp The friction between the fixed clip 2 and the filter cartridge 1 is greater than the friction between the outer fixed clip 3 and the filter cartridge 1, and the inner fixed clip 2 and the outer fixed clip 3 both include two oppositely arranged clips The rod 31 and the fixed connecting rod 32 and the deflecting connecting rod 33 respectively connected to the ends of the same side of the two clamping rods 31, the middle parts of the fixed connecting rod 32 and the deflecting connecting rod 33 intersec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com