Preparation method and generating device of air aldehyde and odor removing spray liquid

A generating device and spray liquid technology, which is applied in the field of air purification, can solve problems such as unsatisfactory effects, and achieve good aldehyde removal effects and low concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

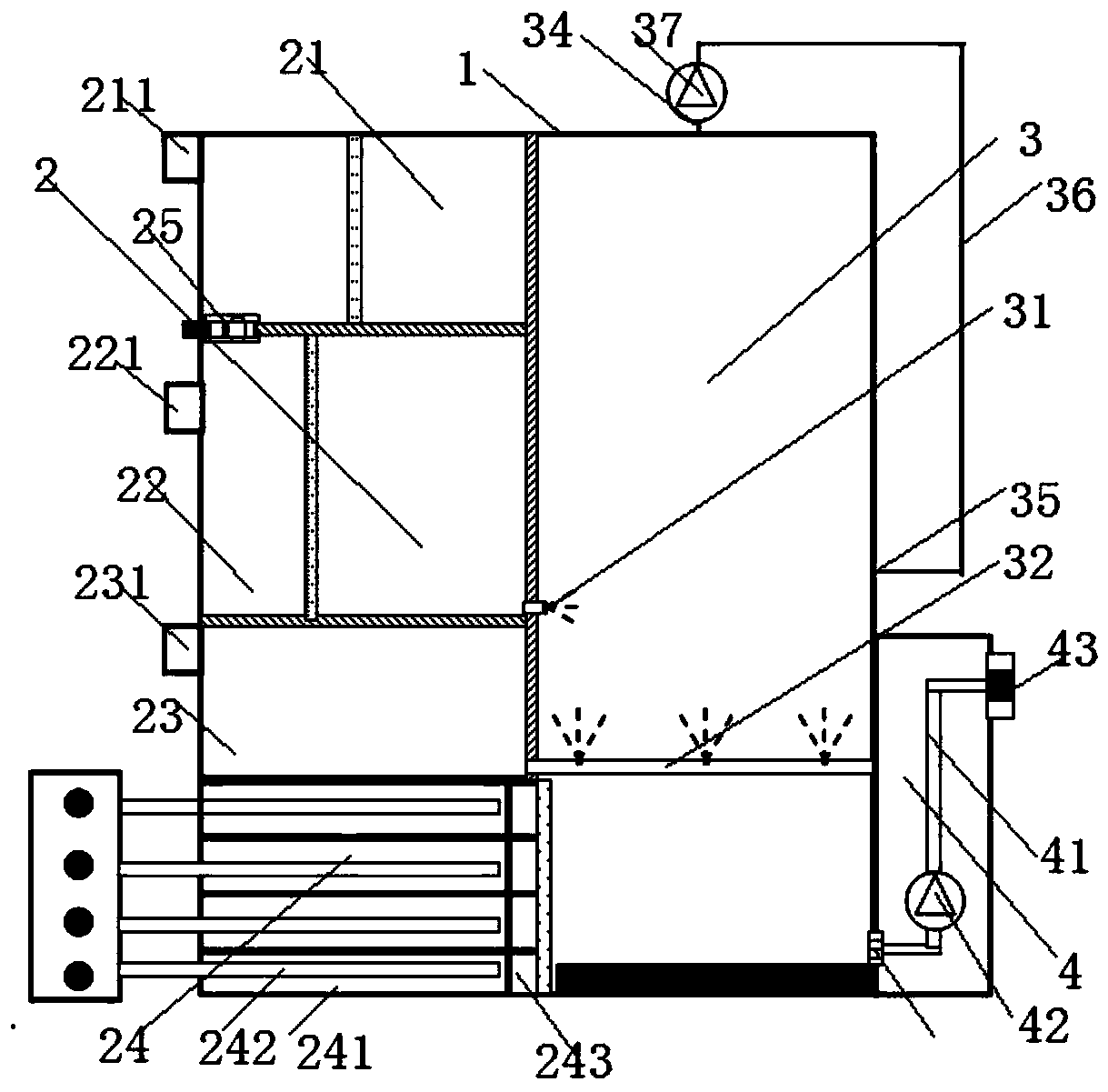

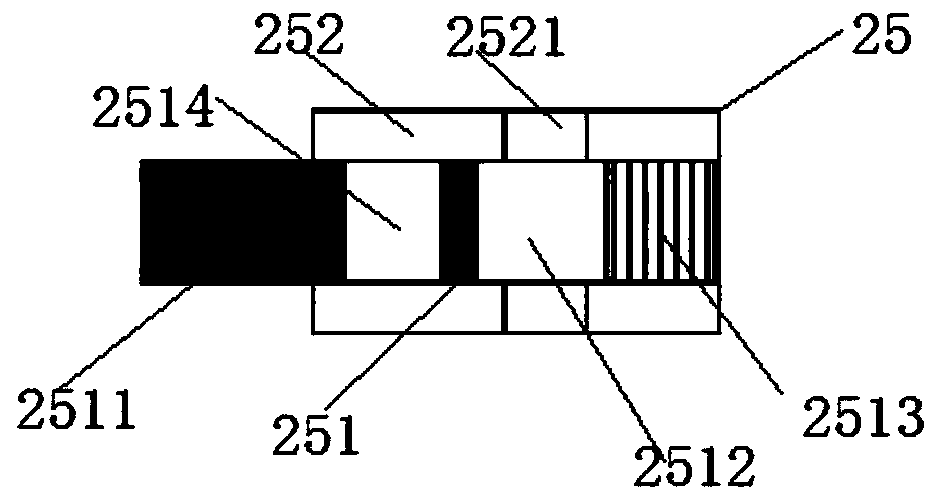

[0029] see Figure 1-Figure 2 1. A generating device for air aldehyde-removing and odor-removing spray liquid, comprising a housing 1, a liquid storage area 2, a mixing area 3 and a spray area 4 are sequentially arranged inside the housing 1 from left to right;

[0030] The liquid storage area 2 includes a first component chamber 21, a second component chamber 22, a third component chamber 23 and a dry ice chamber 24 arranged in sequence from top to bottom;

[0031] The mixing zone 3 comprises an ultrasonic spray pipe 31, a liquid spray pipe 32 and an ultrasonic generator 33, and the ultrasonic spray pipe 31 comprises a liquid storage pipeline and an ultrasonic atomizing nozzle installed on the liquid storage pipeline, and the liquid spray pipe 32 Including the liquid storage pipeline and the nozzle on the installed liquid storage pipeline, the ultrasonic generator 33 is arranged at the bottom of the mixing zone 3;

[0032] The bottom wall of the first component chamber 21 is...

Embodiment 2

[0039] see Figure 1-Figure 2 , as an improvement of the present invention, the first component chamber 21 is provided with a viewing window, and a scale is provided on the viewing window. It is convenient to observe the addition amount of the first component.

Embodiment 3

[0041] see Figure 1-Figure 2 , as an improvement of the present invention, the second component chamber 22 is provided with a viewing window, and a scale is provided on the viewing window. It is convenient to observe the addition amount of the second component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com