Automatic paint spraying device of sheet material

A panel and lifting plate technology, applied in the field of painting, can solve the problems of unsatisfactory painting effect, high manual labor intensity, insufficient automation, etc., and achieve the effect of good painting effect, high degree of mechanization and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other; the following describes the present invention in detail with reference to the accompanying drawings and in combination with the embodiments.

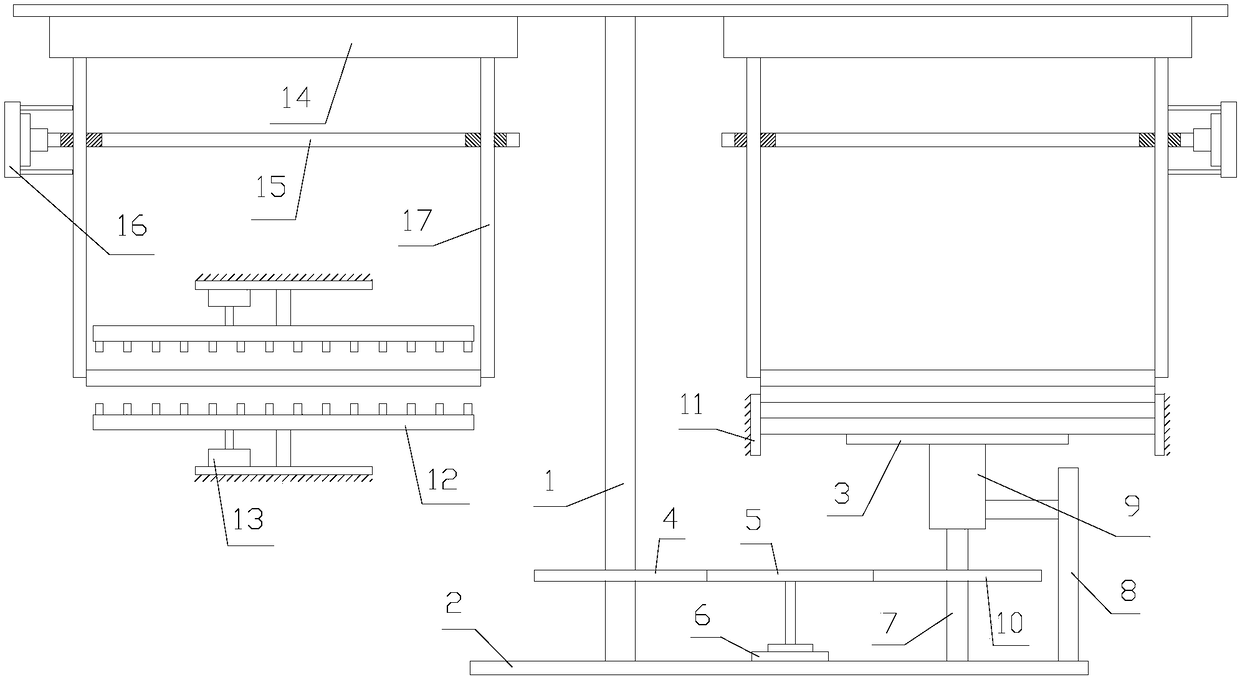

[0017] refer to figure 1 , a kind of board automatic painting device that the present invention proposes, comprises support shaft 1, base 2, a plurality of clamping units, driving mechanism, lifting plate 3, power mechanism; Spraying part; Support shaft 1 and base 2 are rotationally connected; The clamping units are evenly distributed around the circumference of the support shaft 1, and multiple clamping units are connected to the support shaft 1. The clamping units are used to clamp the plate; the driving mechanism is used to drive the support shaft 1 to rotate; the lifting plate 3 is used to place the plate The power mechanism is used to drive the lifting plate 3 to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap