Water curtain paint spraying machine

A paint spraying machine and water curtain technology, which is applied in the field of paint spraying machines, can solve the problems that paint mist cannot be effectively absorbed and removed, inconvenient cleaning and maintenance, and affect the quality of spray paint, etc., and achieve the effects of easy maintenance and cleaning, simple and reasonable structure, and improved paint quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

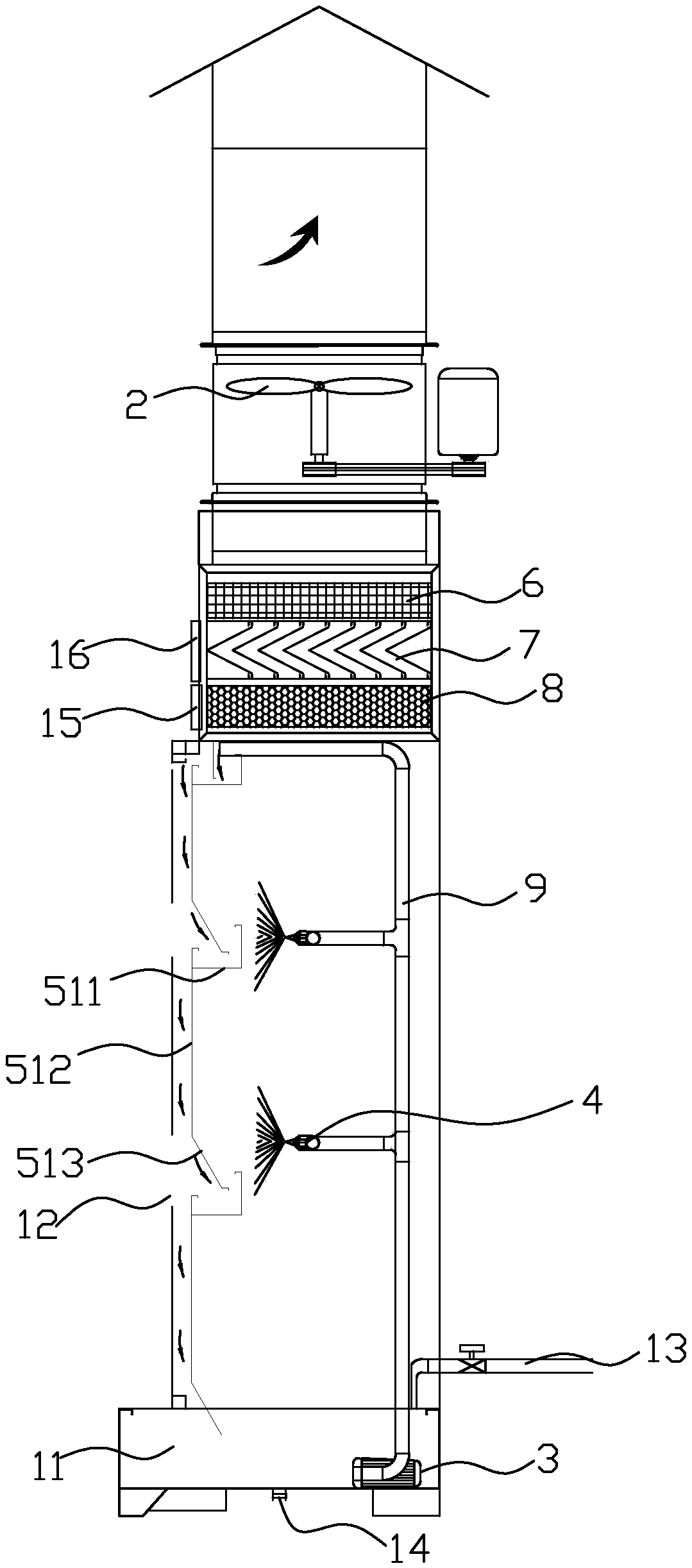

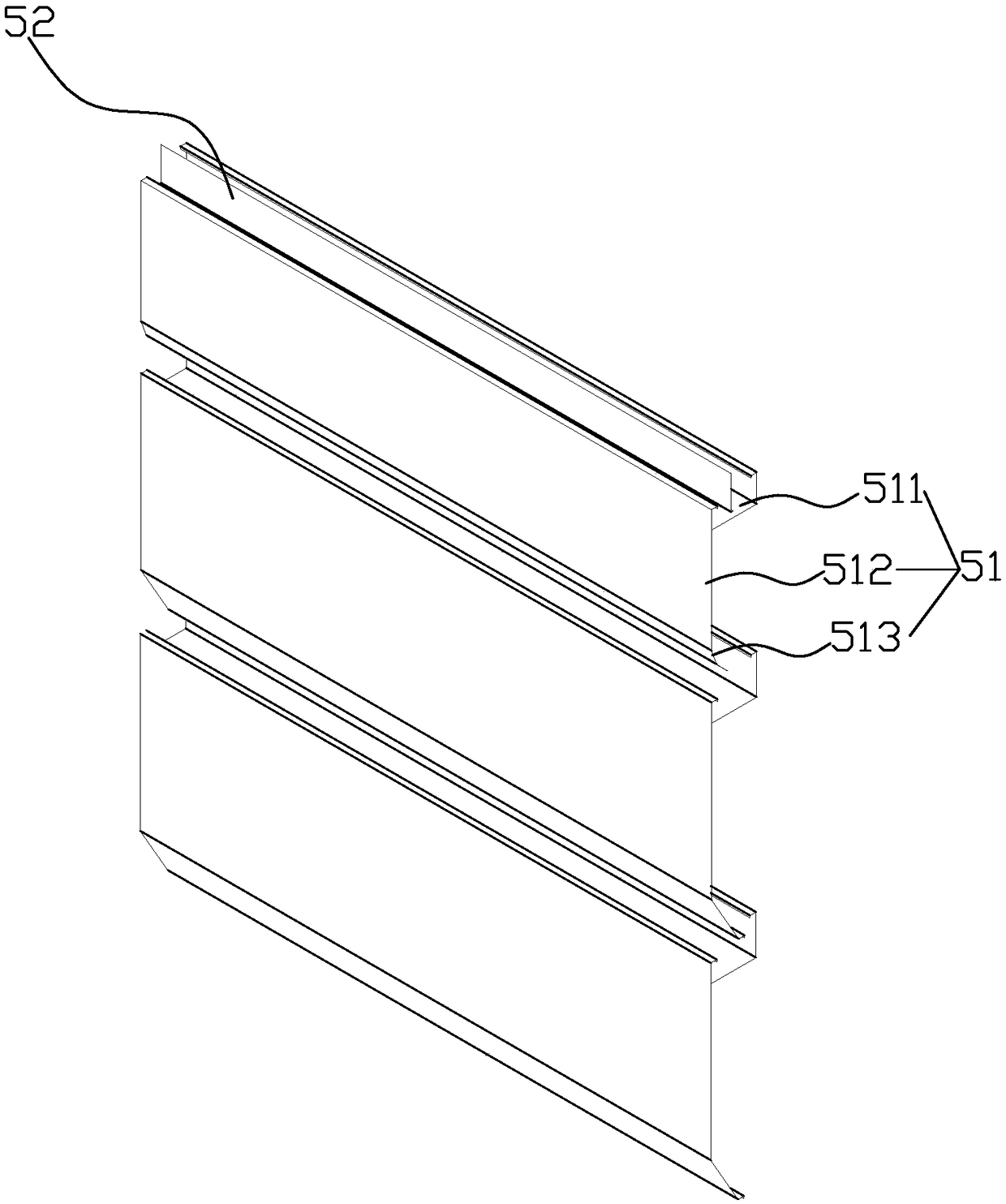

[0016] refer to figure 1 , figure 2 with image 3 , the preferred water curtain painting machine of the present invention includes a water curtain cabinet, and the water curtain cabinet includes a cabinet body 1, an axial flow induced draft fan 2, a water pump 3, a plurality of fine atomizing nozzles 4, a multi-stage water curtain plate, Activated carbon adsorption mechanism 6, water-gas separation mechanism 7 and hollow ball filter layer 8, the multi-stage water curtain plate includes three water curtain plate units 51 and an upper partition 52, and each of the water curtain plate units 51 includes an overflow Sink 511 and dripping board 512, described overflowing tank 511 is arranged at the top of dripping board 512 and this overflowing tank 511 upper opening is far away from the slot edge of painting one side higher than the slot edge of the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com