Coating process of water-based colorful paint on furniture surface

A coating process and colorful paint technology, which is applied in the field of furniture manufacturing, can solve the problems of easy paint peeling of the top coat, lower furniture aesthetics, and poor bonding firmness, so as to improve gloss, not easy to delaminate, easy to change effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of coating process of water-based colorful paint on furniture surface, it is characterized in that, comprises the following steps:

[0028] 1) Plate pretreatment: Use 24# sandpaper to roughly grind until the plate is flat, then wipe the plate with a damp cloth; use 180# sandpaper to finely polish along the direction of the wood grain of the plate to remove burrs, and then remove dust;

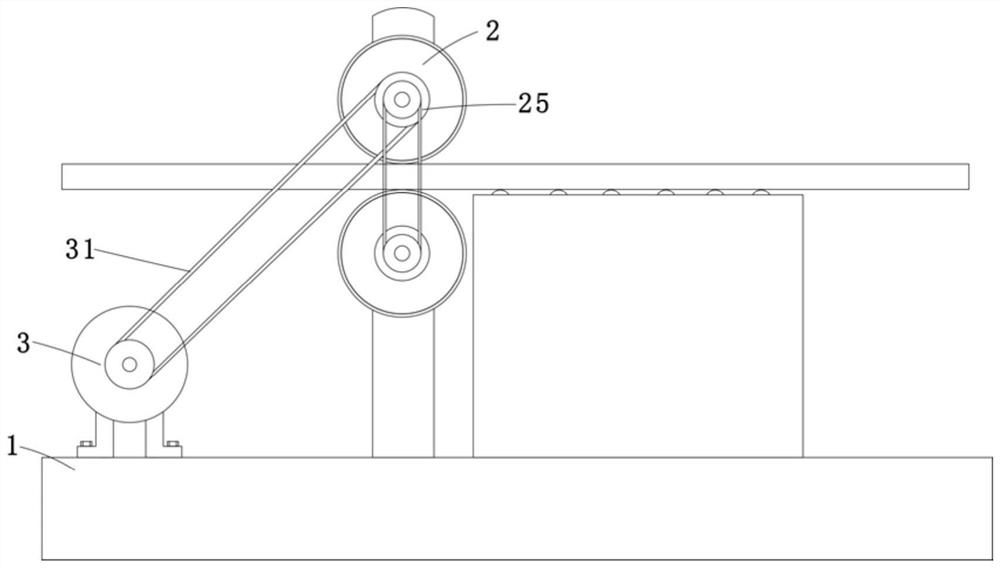

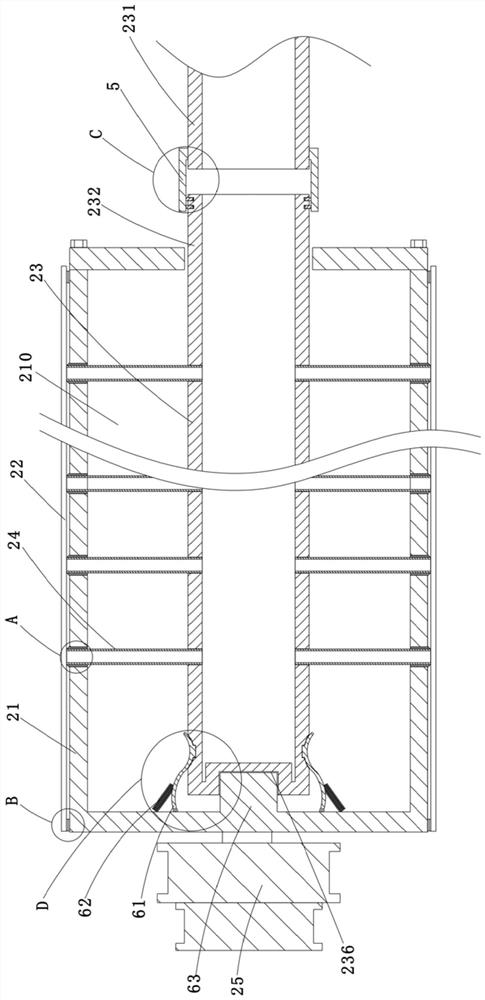

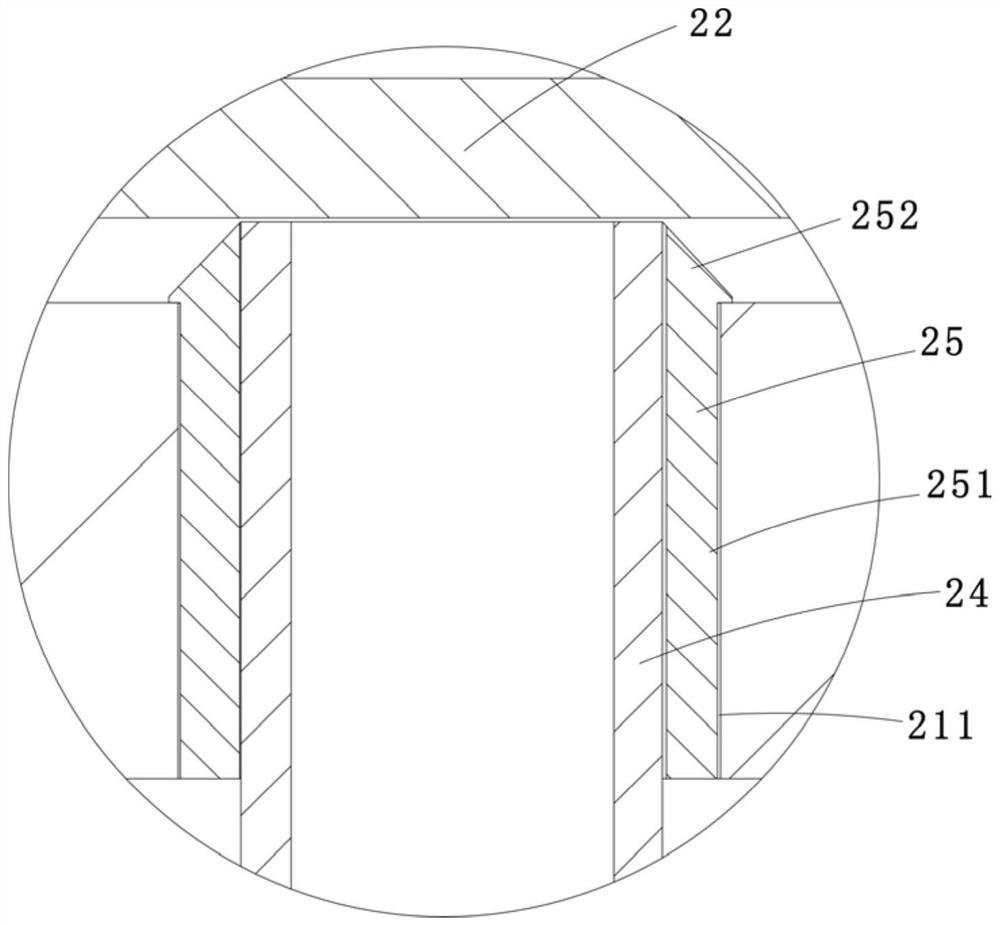

[0029] 2) Paint the board: use paint roller coating equipment to spray primer on the board, and the thickness of the primer is 0.5-0.7mm;

[0030] 3) Spray paint: Spray water-based wood finish paint for 8 seconds, spray evenly;

[0031] 4) Drying: Put the plate that has been sprayed in step 3) in an oven with an initial temperature of 135°C for preliminary drying for 8 minutes; stop the heat source of the oven, and quickly extract the air in the oven for 10 minutes; after extracting the air The temperature in the oven was maintained at 42°C, dried at 42°C for 3 hours, and finally...

Embodiment 2

[0035] A kind of coating process of water-based colorful paint on furniture surface, it is characterized in that, comprises the following steps:

[0036] 1) Plate pretreatment: Use 24# sandpaper to roughly grind until the plate is flat, then wipe the plate with a damp cloth; use 180# sandpaper to finely polish along the direction of the wood grain of the plate to remove burrs, and then remove dust;

[0037] 2) Paint the board: use paint roller coating equipment to spray primer on the board, and the thickness of the primer is 0.5mm;

[0038] 3) Spray paint: Spray water-based wood finish paint for 7 seconds, spray evenly;

[0039] 4) Drying: Put the plate that has been sprayed in step 3) in an oven with an initial temperature of 100°C for preliminary drying for 6 minutes; stop the heat source of the oven, and quickly extract the air in the oven for 8 minutes; after extracting the air The temperature in the oven is maintained at 38-45°C, dried at 38°C for 2 hours, and finally ta...

Embodiment 3

[0043] A kind of coating process of water-based colorful paint on furniture surface, it is characterized in that, comprises the following steps:

[0044] 1) Plate pretreatment: Use 24# sandpaper to roughly grind until the plate is flat, then wipe the plate with a damp cloth; use 180# sandpaper to finely polish along the direction of the wood grain of the plate to remove burrs, and then remove dust;

[0045] 2) Paint the board: use paint roller coating equipment to spray primer on the board, and the thickness of the primer is 0.7mm;

[0046] 3) Spray paint: Spray water-based wood finish paint for 10 seconds, spray evenly;

[0047] 4) Drying: Put the plate that has been sprayed in step 3) in an oven with an initial temperature of 160°C for preliminary drying for 10 minutes; stop the heat source of the oven, and quickly extract the air in the oven for 12 minutes; after extracting the air The temperature in the oven was maintained at 45°C, dried at 45°C for 5 hours, and finally t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com