Auxiliary tool for fixing electronic component to PCB to be welded

A technology for PCB circuit boards and electronic components, which is applied in the direction of assembling printed circuits, electrical components, auxiliary devices, etc. with electrical components, and can solve the problems of broken electronic components, unmelted bodies, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

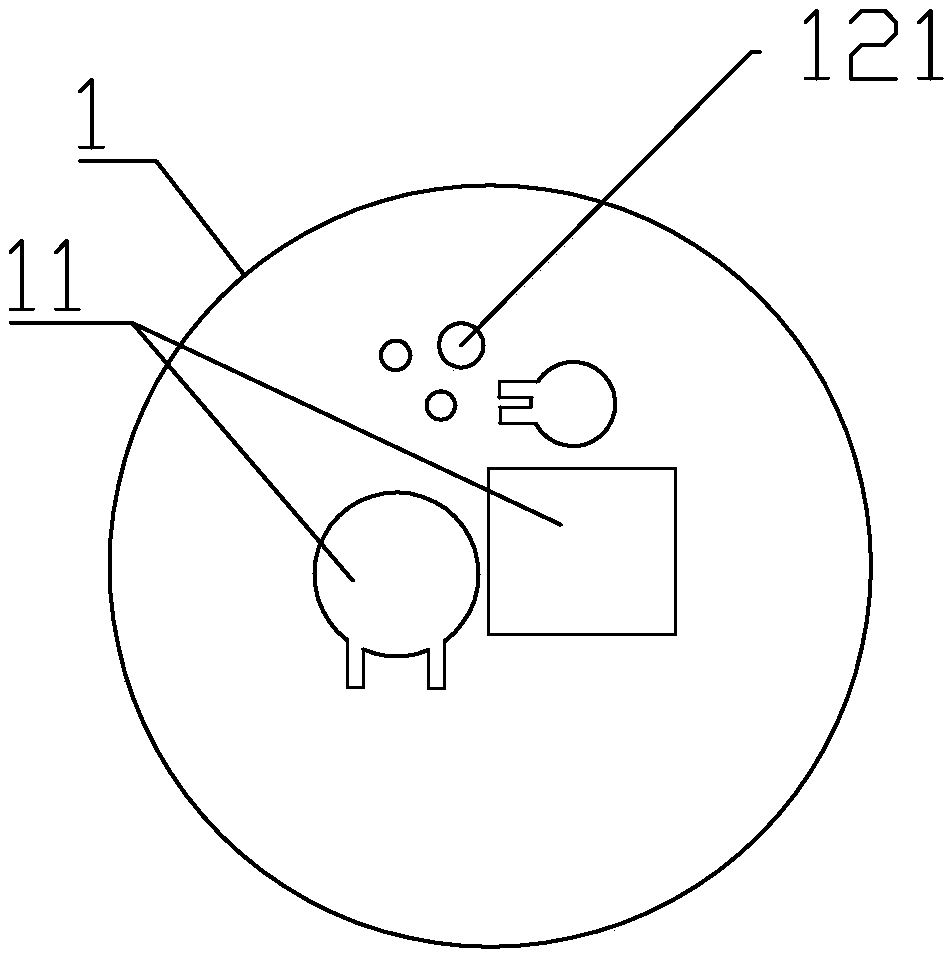

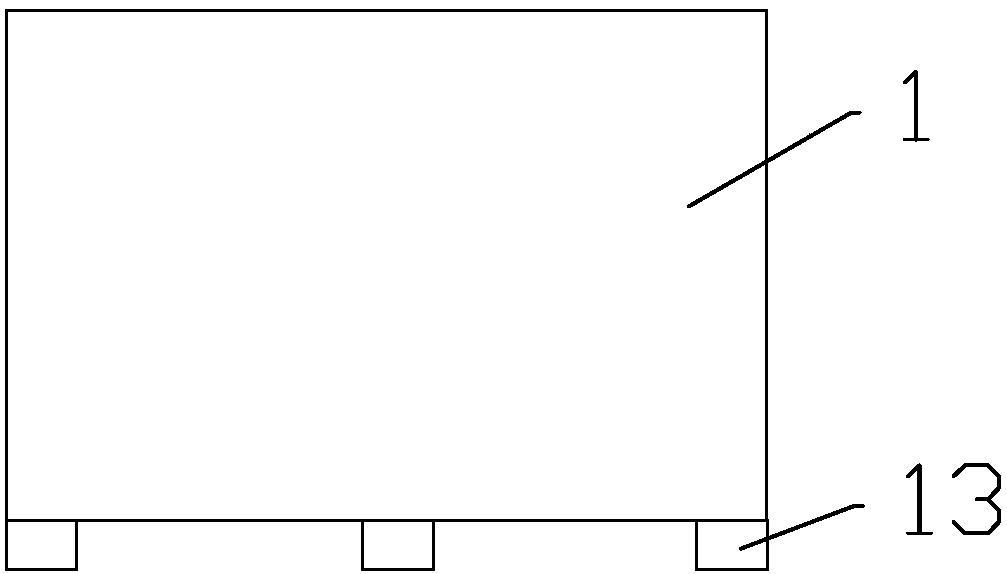

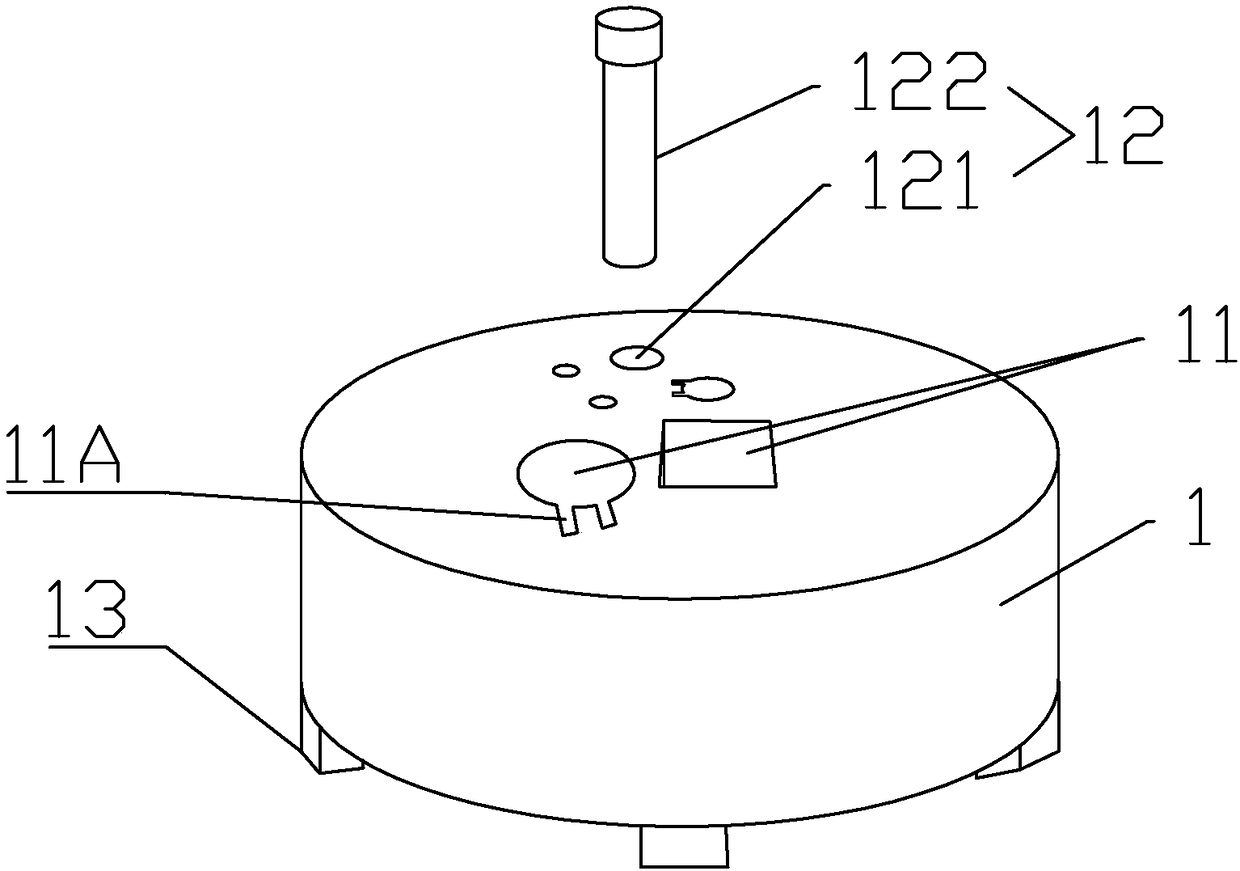

[0049] Such as Figure 4 , Figure 5 Shown: an auxiliary tool for fixing electronic components on a PCB circuit board for welding, the auxiliary tool is an electronic component positioning block, when in use, the electronic component positioning block is placed on the surface of the PCB circuit board through the foot pad, and the electronic component The top of the device positioning block is provided with a lead wire A welded on the PCB circuit board to designate a lead insertion through hole 11 corresponding to the lead A pin solder paste contact A1, and the lead insertion through hole 11 is circular; the electronic component positioning block 1 The bottom is fixed with a foot pad 13; the electronic component positioning block 1 is provided with a positioning device 12 that cooperates with the PCB circuit board 2 to fix the position. The positioning device 12 includes a positioning through hole 121 located at the top of the electronic component, and the positioning through h...

Embodiment 2

[0051] Such as Image 6 , Figure 7 Shown: an auxiliary tool for fixing electronic components on a PCB circuit board for welding, the auxiliary tool is an electronic component positioning block 1, when in use, the electronic component positioning block 1 is placed on the surface of the PCB circuit board 2 through the foot pad 13, The top of the electronic component positioning block 1 is provided with the electronic transformer insertion through-hole 11 that matches the electronic transformer B to be welded on the PCB circuit board 2 to designate corresponding electronic transformer pin solder paste contacts B1, B2, B3, B4. The hole is rectangular, corresponding to the shape of the electronic transformer, and the electronic transformer has four legs, corresponding to the solder paste contacts B1, B2, B3, B4; the bottom of the electronic component positioning block is fixed with a foot pad 13; the electronic component positioning block 1 is provided with a positioning device 1...

Embodiment 3

[0053] Such as Figure 8 , Figure 9 Shown: an auxiliary tool for fixing electronic components on a PCB circuit board for welding, the auxiliary tool is an electronic component positioning block 1, when in use, the electronic component positioning block 1 is placed on the surface of the PCB circuit board 2 through the foot pad 13, The top of the electronic component positioning block 1 is provided with a capacitor C that matches the "L"-shaped pin and is welded on the PCB circuit board 2 to designate a capacitor insertion through hole 11 corresponding to the capacitor pin solder paste contacts C1 and C2, and the capacitor is inserted into the through hole 11 It is circular, and the capacitor has two pins, corresponding to the solder paste contacts C1 and C2. The wall of the capacitor insertion through hole 11 is provided with two pin positioning through grooves 11A for the insertion of the capacitor pins; the bottom of the electronic component positioning block 1 Foot pads 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com