Water guide laser processing method and system

A laser processing method and laser processing technology, which are applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as ablation nozzles, water beam deflection, and easy damage, so as to reduce equipment costs and maintenance costs, Reducing the requirements for laser focus accuracy and stabilizing processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

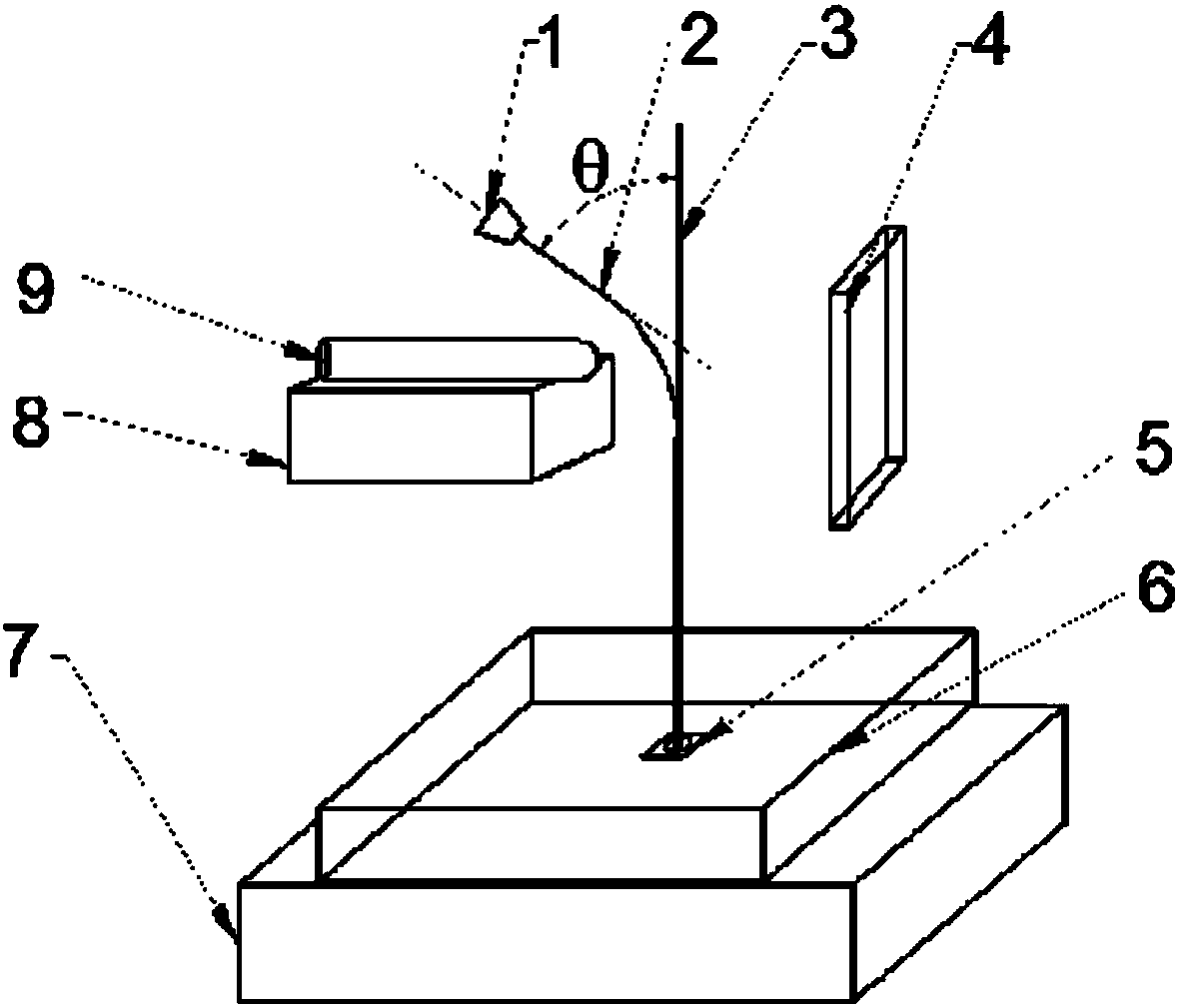

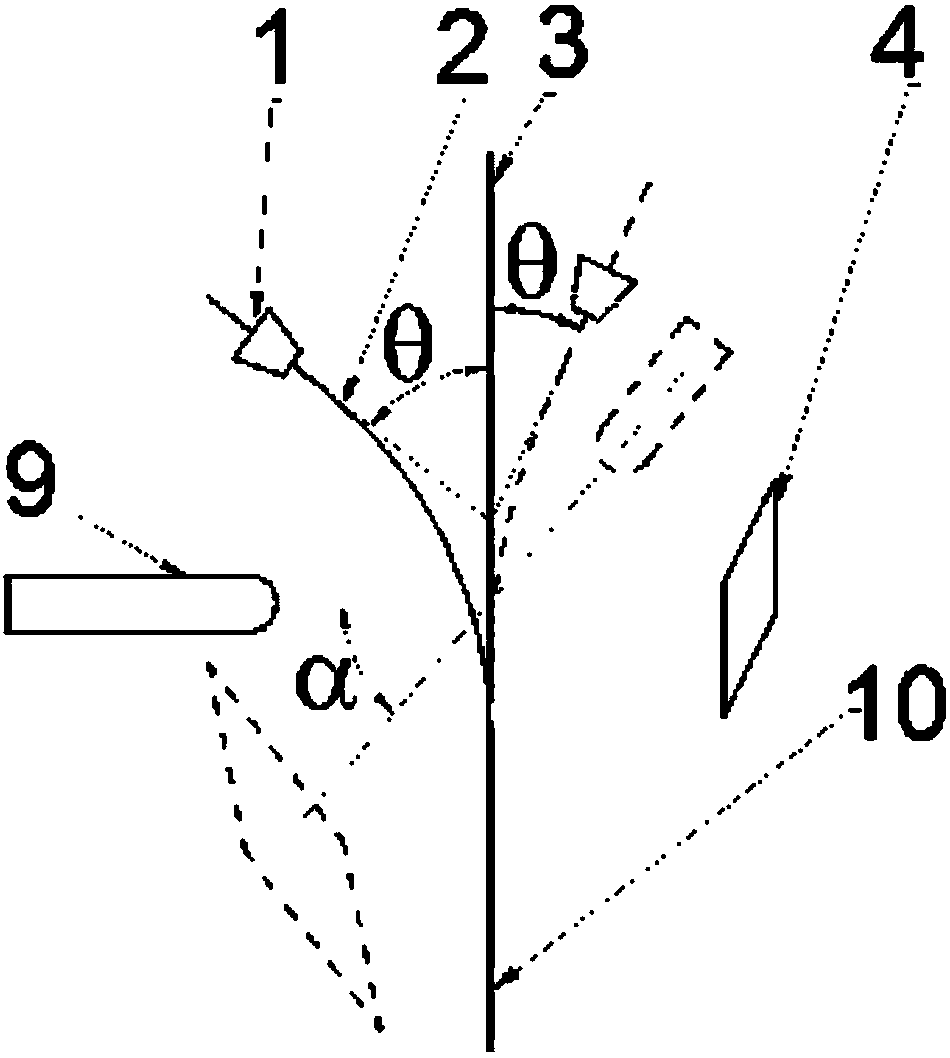

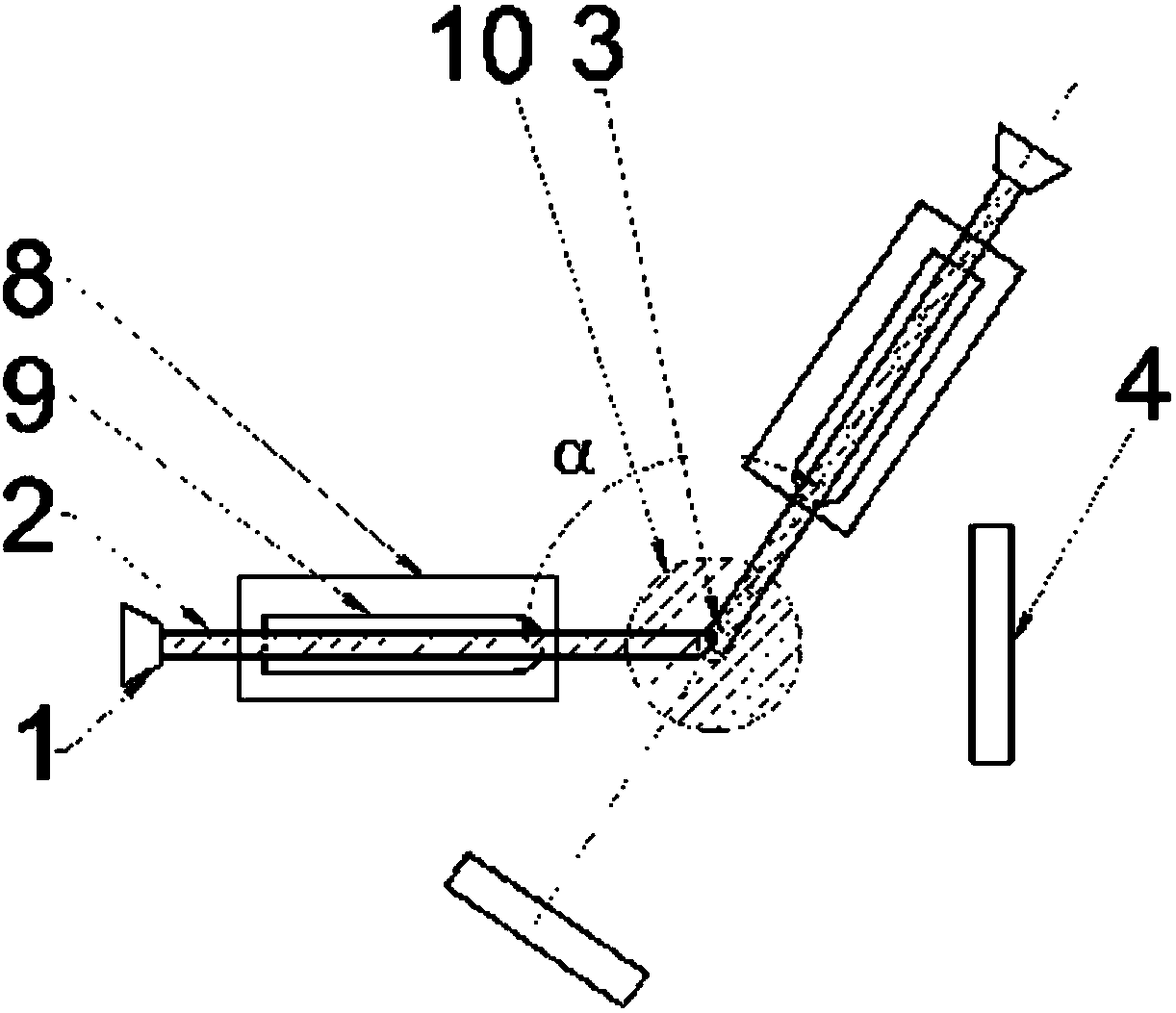

[0035] Embodiment 2 of this water guide laser processing system is as figure 2 and 3 As shown, this example is equipped with 2 sets of water beam deflecting devices, and the water beams deflected by the 2 sets of water beam deflecting devices are combined into a total water beam 10 flowing vertically downward, and the laser beam 3 is focused in the total water beam 10 . The laser beam 3 coincides with the centerline of the total water beam 10 . The angle α between the centerlines of the electrode rods of the two sets of deflecting water beam devices and the vertical plane formed by the centerlines of the laser beams 3 is 120°.

[0036] One of the 2 sets of deflecting water beam devices in this example is the same as the deflecting water beam device described in Embodiment 1 above.

[0037] The distance between the outlet of nozzle 1 and the center line of laser beam 3 of another set of deflecting water beam device is 25 mm, and the distance between the outlet of nozzle 1 and ...

Embodiment 3

[0039] Embodiment 3 of the water-conducting laser processing system is as follows: Figure 4 As shown, this example is equipped with 3 sets of deflecting water beam devices as described in Embodiment 1 above, and the water beams deflected by each set of deflecting water beam devices are combined into a total water beam 10 flowing vertically downward, and the laser beam 3 is focused on the total water beam 10. Inside the water beam 10. The included angle between the centerlines of the electrode rods of the three sets of deflecting water beam devices and the vertical plane formed by the three centerlines of the laser beams is 120°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com