Heat-dissipating and cooling device of injection mould

An injection mold, heat dissipation and cooling technology, applied in the field of heat dissipation and cooling devices, can solve problems such as poor cooling effect of injection molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

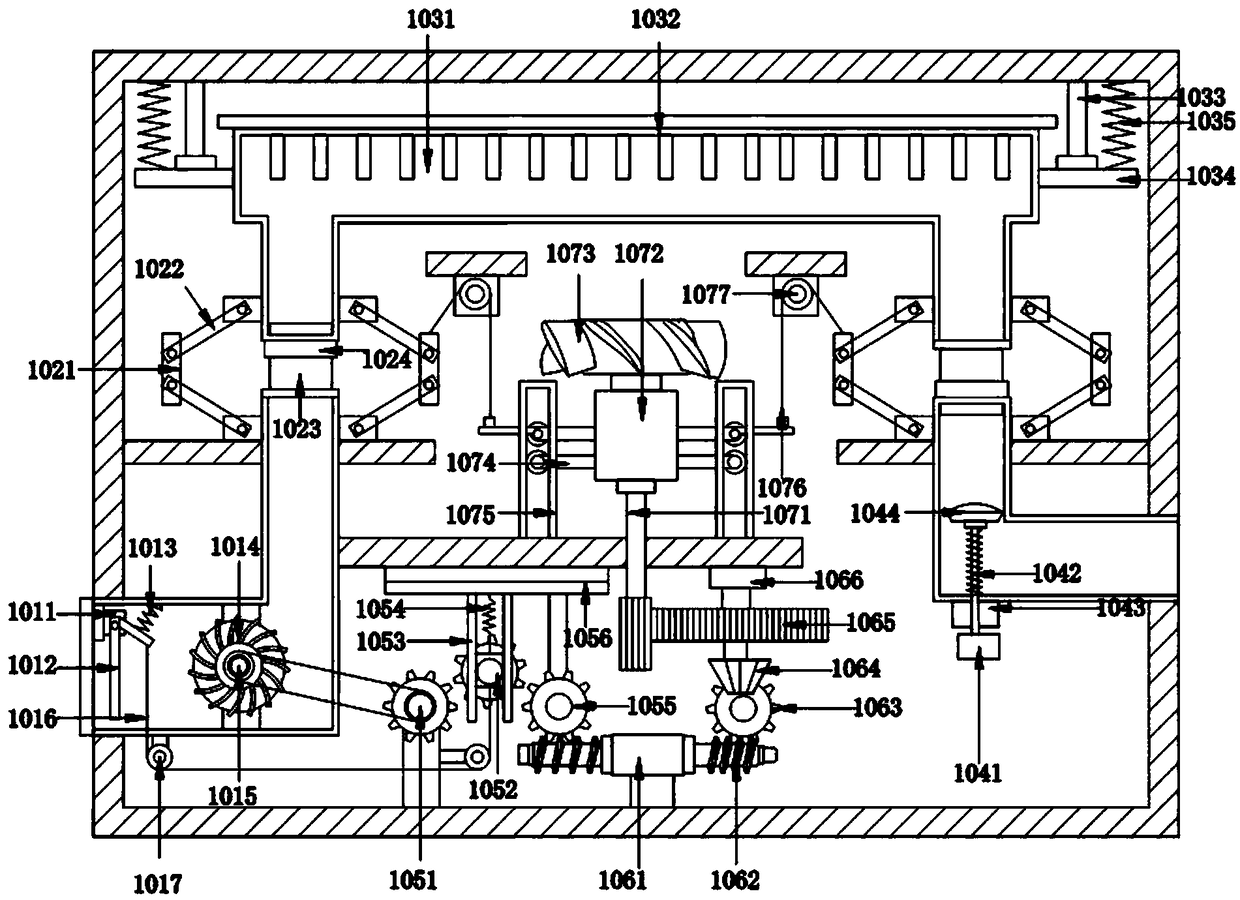

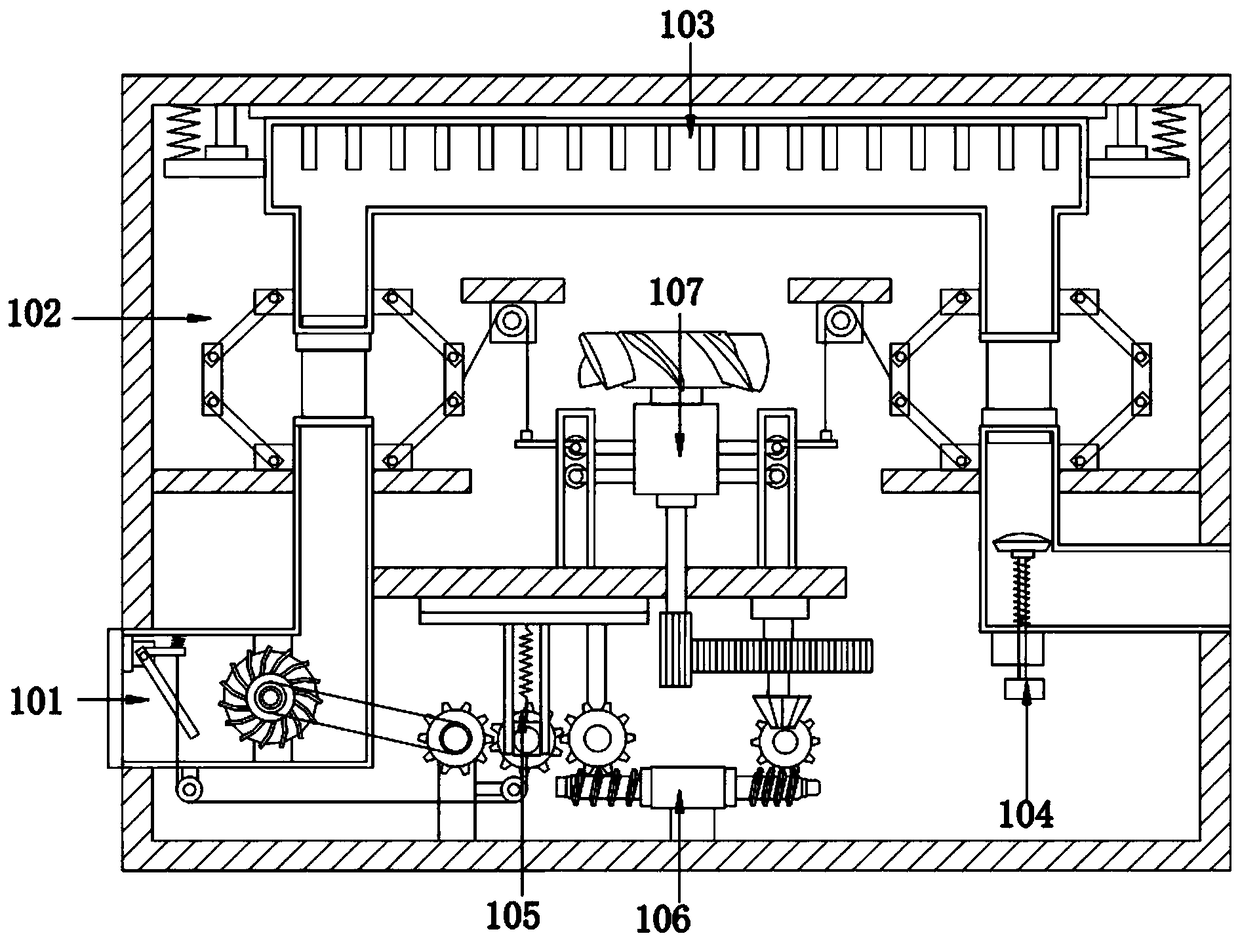

[0018] A heat dissipation and cooling device for an injection mold, comprising a radiator arranged at the lower end of the fixed mold in the injection mold, the radiator is provided with a water inlet pipe 101, a connecting pipe base 102, a water cooling box 103, a flow control piston 104, a connecting gear set 105, a driving Worm screw 106, fan 107 and water outlet pipe, the inner upper end of radiator is provided with water-cooled box 103, and one end of water-cooled box 103 communicates with water inlet pipe 101 through connecting tube base 102, and the other end of water-cooling box 103 communicates with outlet pipe through connecting tube base 102. The water pipe is provided with a flow control piston 104, the rotating impeller 1014 inside the water inlet pipe 101 is mechanically connected with the connecting gear set 105, and the connecting gear set 105 is in clearance fit with the drive worm 106 arranged at the lower end of the fan 107; the flow control piston 104 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com