Processing technology of tempered glass

A kind of tempered glass and processing technology, applied in the direction of glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of unclear nickel sulfide, and achieve the effect of reducing the occurrence of self-explosion, low self-explosion rate, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

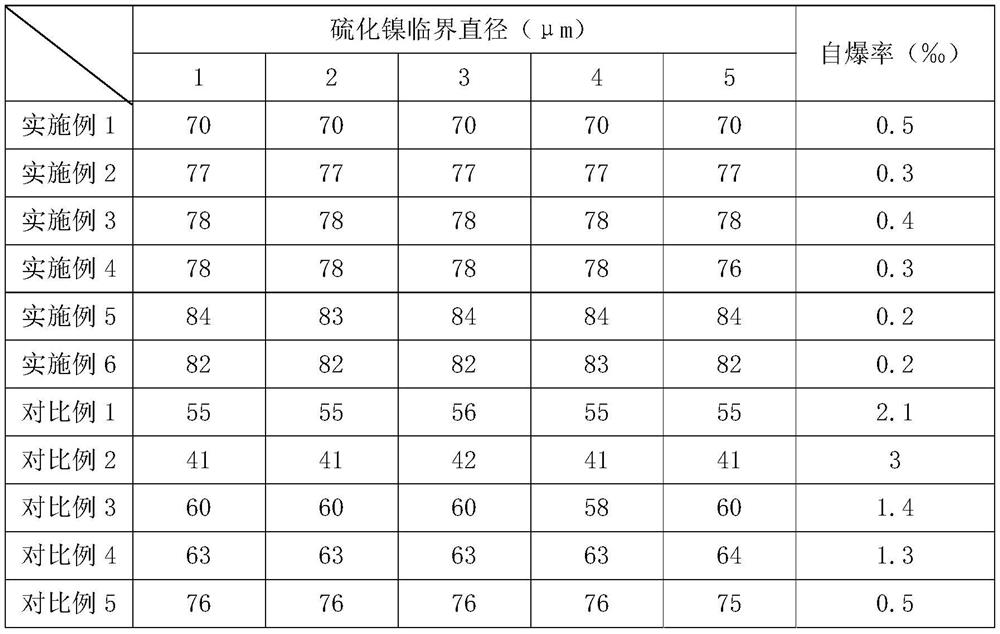

Examples

Embodiment 1

[0019] Embodiment 1: A processing technology of tempered glass, including the following steps, step 1, heating, taking flat glass with a thickness between 5-6mm, putting it into a tempering furnace and heating it to 650°C, and keeping it at 650°C for 3min.

[0020] Step 2, cooling, take out the glass heated in step 1, irradiate the glass with gamma rays at a radiation dose rate of 3.4kGy / h, and blow air evenly on both sides of the glass to cool the glass quickly and uniformly to 250°C.

[0021] Step 3, slowly heating, take the glass cooled to 250°C in step 2, irradiate the glass with gamma rays, the radiation dose rate is 3.4kGy / h, and slowly heat the glass to 270-280°C, the heating rate is 3 ℃ / min, keep warm at 270-280℃ for 10min.

[0022] Step 4, cooling the glass in Step 3 to room temperature, which is 25±5°C, to obtain tempered glass.

Embodiment 2

[0023] Embodiment 2: A processing technology of tempered glass, including the following steps, step 1, heating, taking flat glass with a thickness between 8-15mm, putting it into a tempering furnace and heating it to 700°C, and keeping it at 700°C for 5min.

[0024] Step 2, cooling, take out the heated glass in step 1, irradiate the glass with gamma rays at a radiation dose rate of 10kGy / h, and blow air evenly on both sides of the glass to cool the glass to 220°C quickly and uniformly.

[0025] Step 3, slowly heating, take the glass cooled to 220°C in step 2, irradiate the glass with gamma rays, the radiation dose rate is 10kGy / h, and slowly heat the glass to 270-280°C, the heating rate is 5°C / min, keep warm at 270-280℃ for 15min.

[0026] Step 4, after cooling the glass in step 3 to 100°C, add it into dilute nitric acid at a temperature of 70°C and soak for 20 minutes, and the concentration of dilute nitric acid is 0.1mol / L. After soaking, take out the glass and wash it wit...

Embodiment 3

[0027] Embodiment 3: A processing technology of tempered glass, including the following steps, step 1, take flat glass, the thickness of flat glass is between 20-25mm, put it into a tempering furnace and heat it to 750°C, and keep it at 750°C for 10min .

[0028] Step 2, cooling, take out the heated glass in step 1, irradiate the glass with gamma rays at a radiation dose rate of 16.4kGy / h, and blow air evenly on both sides of the glass to cool the glass to 200°C quickly and uniformly.

[0029] Step 3, slowly heating, take the glass cooled to 200°C in step 2, irradiate the glass with gamma rays, the radiation dose rate is 16.4kGy / h, and slowly heat the glass to 270-280°C, the heating rate is 5 ℃ / min, keep warm at 270-280℃ for 25min.

[0030] Step 4, after cooling the glass in step 3 to 100°C, add it into dilute nitric acid at a temperature of 85°C and soak for 20 minutes, and the concentration of dilute nitric acid is 0.1mol / L. After soaking, take out the glass and wash it wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| stress intensity factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com