A solid mold for tempered glass molding

A toughened glass, solid technology, applied in glass forming, glass remolding, glass manufacturing equipment, etc., can solve the problems of difficult forming of tempered glass, poor appearance quality, low yield, etc., and achieve the effect of saving the company's cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

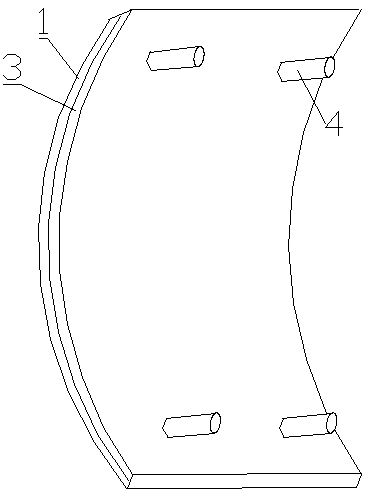

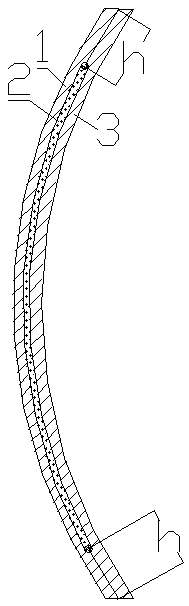

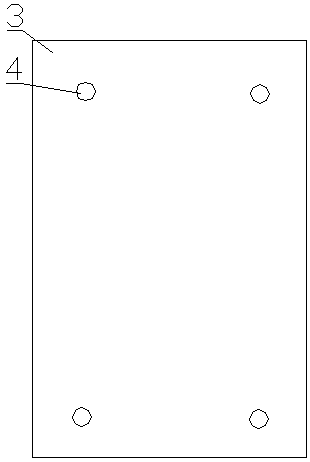

[0025] Embodiment 1: A solid mold for tempered glass molding, which is made by the following steps: ① Spread three layers of glass cloth on the inner surface of the curved tempered glass as convex glass cloth 1; Add a circle of steel bars 2 where the distance h between the inner surface of 1 and the edge of the glass cloth is 100 mm; ③ After adding the steel bars, lay three layers of glass cloth on the steel bars as the concave glass cloth 3; ④ On the inner surface of the concave glass cloth 3 After applying the styling liquid, let it dry for 30 minutes at room temperature. Five fixing modules 4 are also arranged on the inner surface of the concave glass cloth.

[0026] The styling liquid is prepared by mixing the following raw materials in parts by weight: 3 g of 191 unsaturated polyester resin, 0.5 g of benzoyl peroxide, 1.5 g of ketone, and 5 g of isophthalic gel coat.

Embodiment 2

[0027] Embodiment 2: A solid mold for tempered glass molding, which is made by the following steps: ① Spread two layers of glass cloth on the inner surface of the curved tempered glass as convex glass cloth 1; Add a circle of steel bars 2 at the distance h between the inner surface of 1 and the edge of the glass cloth at a distance of 90 mm; ③ After adding the steel bars, lay two layers of glass cloth on the steel bars as the concave glass cloth 3; ④ On the inner surface of the concave glass cloth 3 After applying the styling liquid, dry it at room temperature for 25 minutes. Four fixing modules 4 are also arranged on the inner surface of the concave glass cloth.

[0028] The styling solution is prepared by mixing the following raw materials in parts by weight: 2.5 g of 191 unsaturated polyester resin, 0.7 g of cumin hydroperoxide, 1.2 g of ketone, and 5.5 g of isophthalic gel coat.

Embodiment 3

[0029] Embodiment 3: A solid mold for tempered glass molding, which is made by the following steps: ① Spread a layer of glass silk cloth on the inner surface of the curved tempered glass as convex glass cloth 1; Add a circle of steel bars 2 where the distance h between the inner surface of 1 and the edge of the glass cloth is 110 mm; ③ After adding the steel bars, lay three layers of glass cloth on the steel bars as the concave glass cloth 3; ④ On the inner surface of the concave glass cloth 3 After applying the styling solution, dry it at room temperature for 35 minutes. Six fixing modules 4 are also arranged on the inner surface of the concave glass cloth.

[0030] The styling liquid is prepared by mixing the following raw materials in parts by weight: 3.5 g of 191 unsaturated polyester resin, 0.3 g of di-tert-butyl peroxide, 1.7 g of ketone, and 4.5 g of isophthalic gel coat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com