High borosilicate fireproof tempered glass and tempering method thereof

A technology of tempered glass and high borosilicate, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc. Performance, the effect of excellent tempering strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

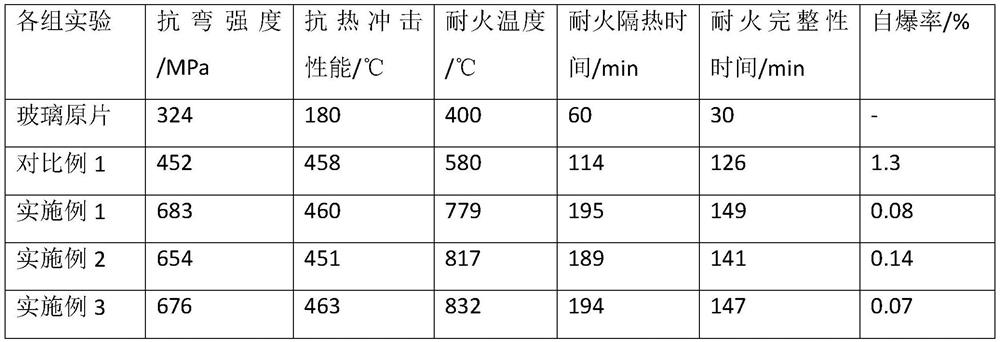

Examples

Embodiment 1

[0027] A tempering method of high borosilicate fireproof tempered glass, carried out according to the following steps:

[0028] (1) Cut the original high borosilicate 4.0 glass sheet into a glass sheet with a thickness of 1mm and a size of 60mm×35mm, then polish and polish the upper and lower surfaces of the glass sheet, and ultrasonically clean it with deionized water;

[0029](2) Add K at a concentration of 0.1mol / L to the glass slide after ultrasonic cleaning 2 Cr 2 o 7 solution, seal and heat to 70°C, keep warm for 3 hours, then filter out the glass sheet and wash it with high-purity water;

[0030] (3) in K 2 Cr 2 o 7 Add KMnO with a concentration of 2mol / L to the hydrothermally treated glass flakes 4 solution, seal and heat to 70°C, keep warm for 3 hours, then filter out the glass sheet and wash it with high-purity water;

[0031] (4) in KMnO 4 Add high-purity water to the hydrothermally treated glass sheet, seal and heat to 100°C, keep warm for 0.5h, then filter...

Embodiment 2

[0035] A tempering method of high borosilicate fireproof tempered glass, carried out according to the following steps:

[0036] (1) Cut the original high borosilicate 4.0 glass sheet into a glass sheet with a thickness of 1mm and a size of 60mm×35mm, then polish and polish the upper and lower surfaces of the glass sheet, and ultrasonically clean it with deionized water;

[0037] (2) Add K with a concentration of 2mol / L to the glass slide after ultrasonic cleaning 2 Cr 2 o 7 solution, seal and heat to 100°C, keep warm for 2 hours, then filter out the glass piece and wash it with high-purity water;

[0038] (3) in K 2 Cr 2 o 7 Add KMnO with a concentration of 4mol / L to the hydrothermally treated glass flakes 4 solution, seal and heat to 100°C, keep warm for 2 hours, then filter out the glass piece and wash it with high-purity water;

[0039] (4) in KMnO 4 Add high-purity water to the hydrothermally treated glass sheet, seal and heat to 100°C, keep warm for 0.5h, then fil...

Embodiment 3

[0043] A tempering method of high borosilicate fireproof tempered glass, carried out according to the following steps:

[0044] (1) Cut the original high borosilicate 4.0 glass sheet into a glass sheet with a thickness of 1mm and a size of 60mm×35mm, then polish and polish the upper and lower surfaces of the glass sheet, and ultrasonically clean it with deionized water;

[0045] (2) Add K at a concentration of 1mol / L to the glass slide after ultrasonic cleaning 2 Cr 2 o 7 solution, seal and heat to 80°C, keep warm for 2.5h, then filter out the glass piece and wash it with high-purity water;

[0046] (3) in K 2 Cr 2 o 7 Add KMnO with a concentration of 3mol / L to the hydrothermally treated glass flakes 4 solution, seal and heat to 90°C, keep warm for 2.5h, then filter out the glass piece and wash it with high-purity water;

[0047] (4) in KMnO 4 Add high-purity water to the hydrothermally treated glass sheet, seal and heat to 100°C, keep warm for 0.5h, then filter out th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com