Compression-resistant and tensile-resistant material for mouse and preparation method of compression-resistant and tensile-resistant material

A tensile material and mouse technology, applied in the field of materials, can solve problems such as easy occurrence of various failures, and achieve the effects of easy industrial production, improved compressive and tensile properties, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

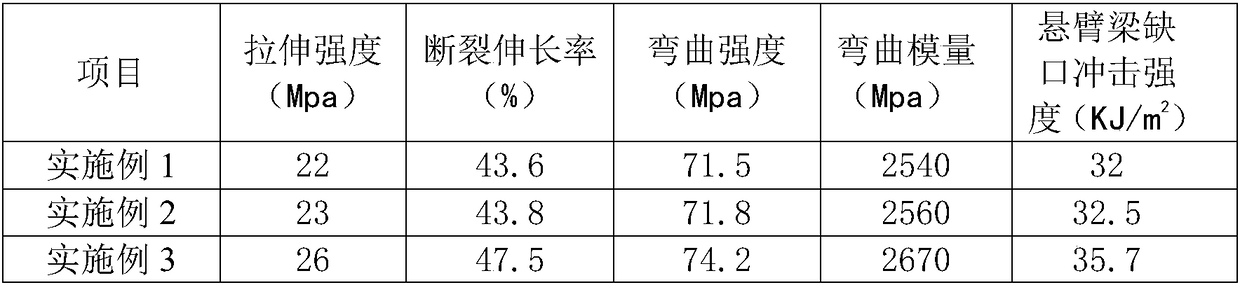

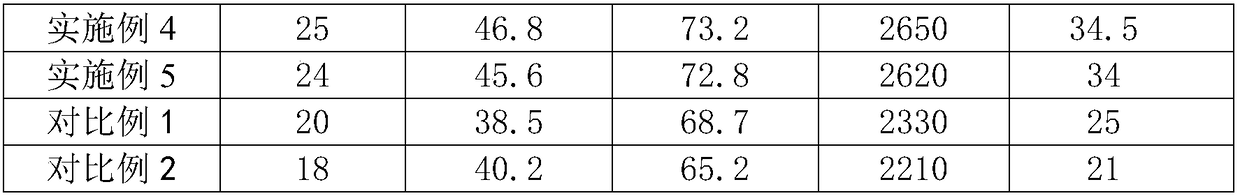

Examples

Embodiment 1

[0025] A compressive and tensile material for a mouse, in parts by weight, the material mainly includes the following components: 22 parts of polycarbonate, 3 parts of composite reinforcing fiber, 13 parts of fluorosilicone rubber, 2 parts of potassium hexatitanate whisker 1 part, 3 parts of inorganic filler, 2 parts of zinc p-tert-butylbenzoate, 1 part of antioxidant, 0.5 part of accelerator, 0.3 part of compatibilizer.

[0026] Wherein, the composite reinforcing fiber is a mixture of carbon fiber and polyimide fiber with a weight ratio of 2:1.

[0027] Wherein, the inorganic filler is a mixture of light calcium carbonate and talcum powder.

[0028] Wherein, the antioxidant is a composition of antioxidant 1010 and antioxidant 168 in a weight ratio of 1:1.

[0029] Wherein, the accelerator is dithiotetramethylthiuram.

[0030] Wherein, the compatibilizer is maleic anhydride grafted polypropylene.

[0031] The present invention also provides a preparation method of the above...

Embodiment 2

[0036] A compressive and tensile material for a mouse, in parts by weight, the material mainly includes the following components: 42 parts of polycarbonate, 8 parts of composite reinforcing fiber, 26 parts of fluorosilicone rubber, and 8 parts of potassium hexatitanate whiskers 6 parts, 6 parts of inorganic filler, 6 parts of zinc p-tert-butylbenzoate, 5 parts of antioxidant, 1.5 parts of accelerator, 0.8 parts of compatibilizer.

[0037] Wherein, the composite reinforcing fiber is a mixture of carbon fiber and polyimide fiber with a weight ratio of 4:1.

[0038] Wherein, the inorganic filler is a mixture of calcined kaolin and heavy calcium carbonate.

[0039] Wherein, the antioxidant is a composition of antioxidant 1010 and antioxidant 168 in a weight ratio of 1:1.

[0040] Wherein, the accelerator is dithiotetramethylthiuram.

[0041] Wherein, the compatibilizer is maleic anhydride grafted polypropylene.

[0042] The present invention also provides a preparation method o...

Embodiment 3

[0047] A compressive and tensile material for a mouse, in parts by weight, the material mainly includes the following components: 30 parts of polycarbonate, 5.5 parts of composite reinforcing fiber, 19 parts of fluorosilicone rubber, 5 parts of potassium hexatitanate whisker 4.5 parts of inorganic filler, 4 parts of zinc p-tert-butylbenzoate, 3 parts of antioxidant, 1 part of accelerator, and 0.5 parts of compatibilizer.

[0048] Wherein, the composite reinforcing fiber is a mixture of carbon fiber and polyimide fiber with a weight ratio of 3:1.

[0049] Wherein, the inorganic filler is a mixture of talcum powder, calcined kaolin and heavy calcium carbonate.

[0050] Wherein, the antioxidant is a composition of antioxidant 1010 and antioxidant 168 in a weight ratio of 1:1.

[0051] Wherein, the accelerator is dithiotetramethylthiuram.

[0052] Wherein, the compatibilizer is maleic anhydride grafted polypropylene.

[0053] The present invention also provides a preparation me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Izod notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com