Water-blocking composite cable for offshore oil platform

A technology of offshore oil and composite cables, applied in the direction of insulating cables, cables, circuits, etc., to achieve the effects of improving mechanical stability, improving hydrophobicity, and improving surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

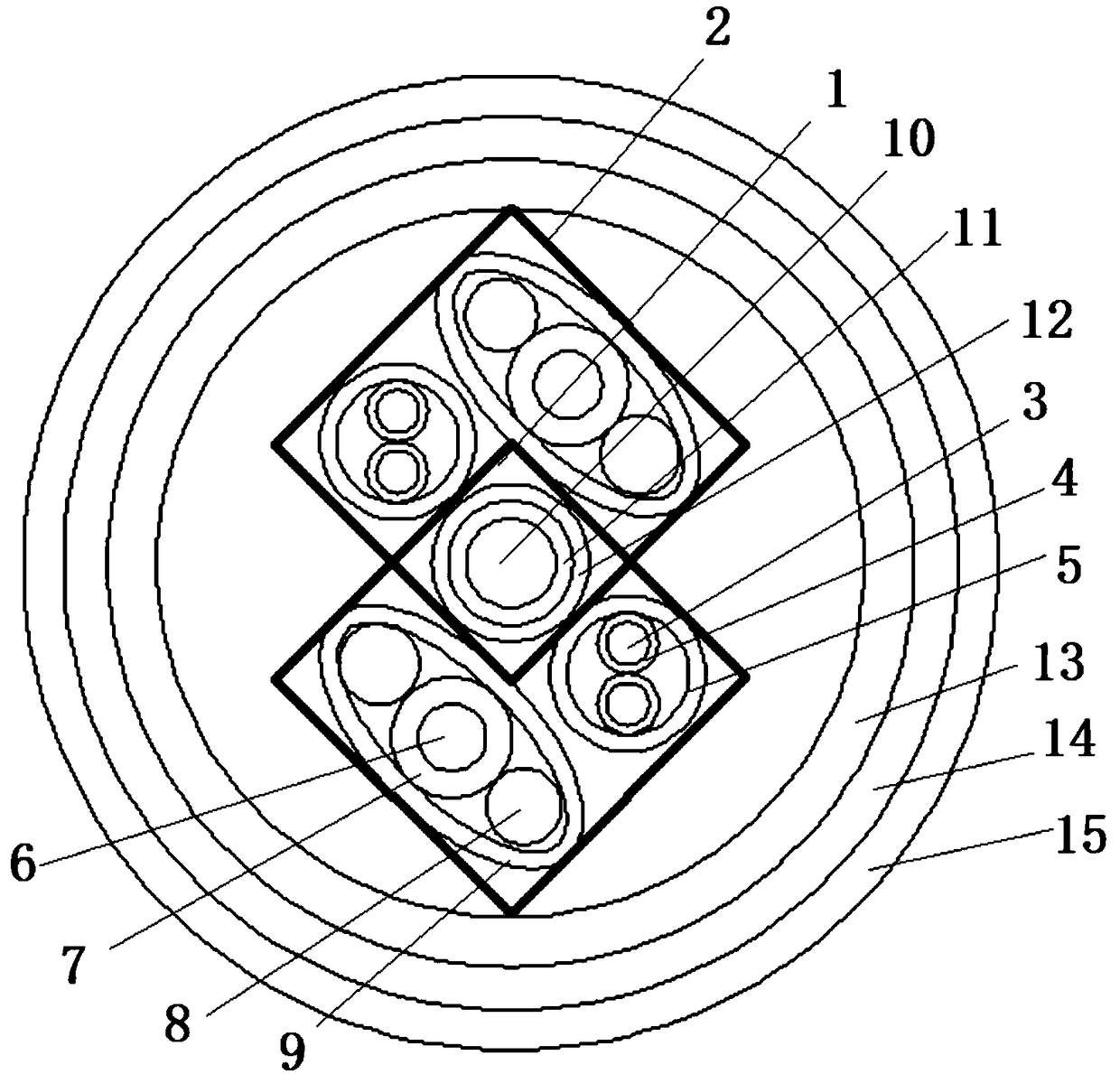

[0020] like figure 1 As shown, a water-blocking composite cable for an offshore oil platform includes a cable core, and the cable core includes a skeleton. The skeleton includes two partially overlapping square skeletons. The frame is the sub-frame 2, the main frame 1 and the sub-frame 2 are integrated structure; the main frame 1 is provided with a power wire core, and each sub-frame 2 is respectively provided with a control wire core and a The communication wire core and the control wire core include two conductors 3, each conductor 3 is covered with a silicone rubber insulating layer 4 and twisted, and the two twisted conductors 3 are wrapped with water-blocking aramid yarn Layer 5, the communication core includes a conductor 6, the conductor 6 is covered with an ethylene-propylene rubber insulating layer 7, and then twisted with two circular polyurethane elastomers 8, and the twisted conductor 6 is covered with a water-blocking aromatic Aramid yarn wrapping layer 9, the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com