A kind of low-carbon v-n-nb microalloyed hot-rolled strip steel and its preparation method

A hot-rolled strip and micro-alloying technology, applied in the field of hot-rolled strip manufacturing, can solve the problems of excessive expensive alloying elements, unstable production process, etc., achieve a simple preparation process, and promote the formation of intragranular acicular ferrite. The effect of nuclear, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A low-carbon V-N-Nb microalloyed hot-rolled steel strip with a thickness of 18.0mm, the chemical composition of which is: C: 0.06%, Mn: 2.2%, Si: 0.50%, S: 0.003%, P: 0.015%, Al: 0.0l%, V: 0.15%, N: 0.020%, Nb: 0.06%, Ti: 0.02%, Cr: 0.50%, the balance is Fe and other unavoidable impurities;

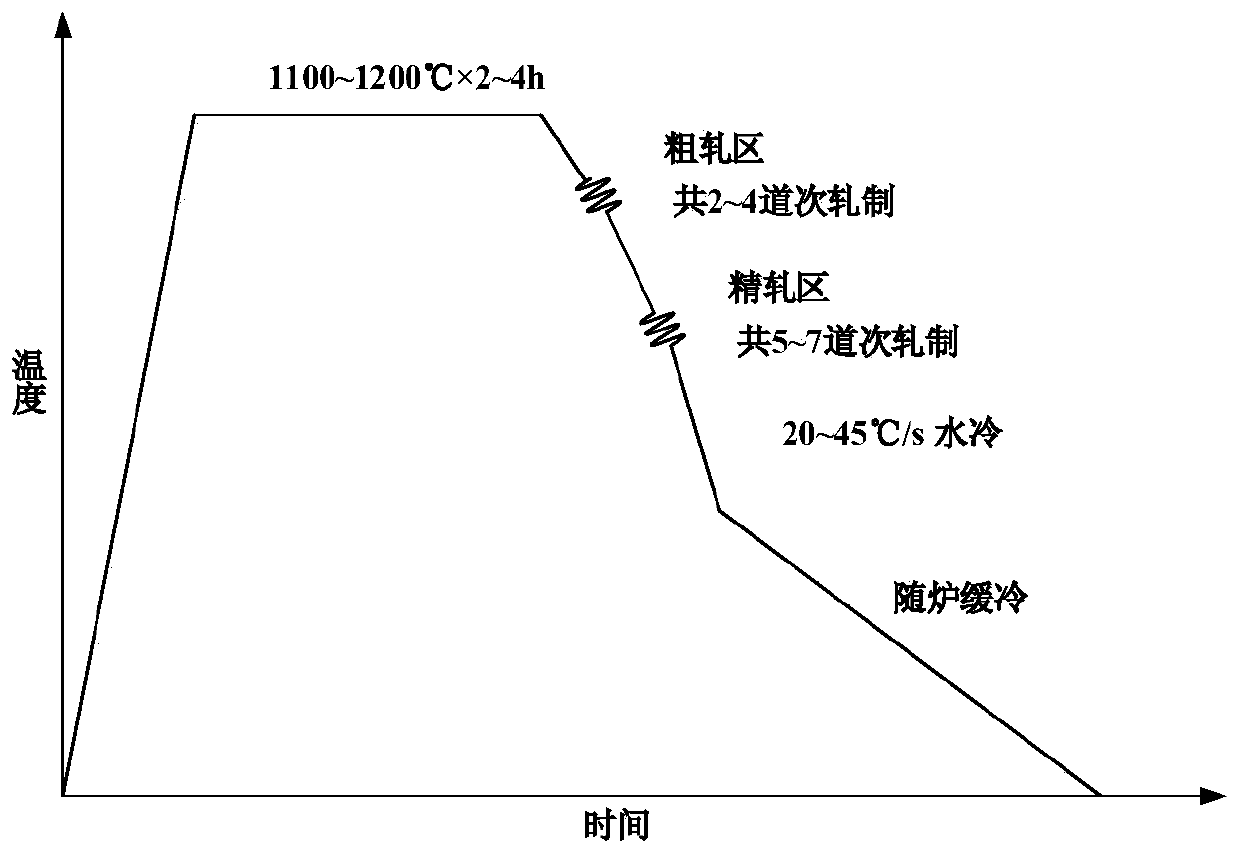

[0041] A kind of preparation method that is 18.0mm low-carbon V-N-Nb micro-alloyed hot-rolled strip steel, specifically comprises the following steps:

[0042] Step 1, casting:

[0043] According to the composition ratio of hot-rolled strip steel, it is smelted at 1550°C, and the obtained molten steel is cast and forged to obtain a billet with a thickness of 130mm;

[0044] Step 2, heating:

[0045] Heat the billet to 1200°C and keep it warm for 4h;

[0046] Step 3, rolling:

[0047] (1) The heated billet is subjected to 2 passes of rough rolling, the starting rolling temperature is 1180°C, the final rolling temperature is 1110°C, the average reduction rate of a single pass is ...

Embodiment 2

[0054] A low-carbon V-N-Nb micro-alloyed hot-rolled steel strip with a thickness of 10.0 mm, its chemical composition by weight percentage is: C: 0.11%, Mn: 1.9%, Si: 0.29%, S: 0.002%, P: 0.009%, Al: 0.05%, V: 0.10%, N: 0.012%, Nb: 0.04%, Ti: 0.015%, Cr: 0.36%, the balance is Fe and other unavoidable impurities;

[0055] A method for preparing a low-carbon V-N-Nb microalloyed hot-rolled steel strip with a thickness of 10.0mm, specifically comprising the following steps:

[0056] Step 1, casting:

[0057] According to the composition ratio of hot-rolled strip steel, it is smelted at 1550°C, and the obtained molten steel is cast and forged to obtain a billet with a thickness of 80mm;

[0058] Step 2, heating:

[0059] Heat the billet to 1150°C and keep it warm for 3h;

[0060] Step 3, rolling:

[0061] (1) The heated billet is subjected to 3 passes of rough rolling, the starting rolling temperature is 1130°C, the final rolling temperature is 1060°C, the average reduction rat...

Embodiment 3

[0068] A low-carbon V-N-Nb microalloyed hot-rolled steel strip with a thickness of 2.5 mm, the chemical composition of which is: C: 0.15%, Mn: 1.5%, Si: 0.10%, S: 0.003%, P: 0.012 %, Al: 0.01%, V: 0.06%, N: 0.008%, Nb: 0.03%, Ti: 0.01%, Cr: 0.20%, the balance is Fe and other unavoidable impurities;

[0069] A kind of thickness is the preparation method of 2.5mm low-carbon V-N-Nb micro-alloyed hot-rolled steel strip, specifically comprising the following steps:

[0070] Step 1, casting:

[0071] According to the composition ratio of hot-rolled strip steel, it is smelted at 1550°C, and the obtained molten steel is cast and forged to obtain a billet with a thickness of 50mm;

[0072] Step 2, heating:

[0073] Heat the billet to 1100°C and keep it warm for 2h;

[0074] Step 3, rolling:

[0075] (1) The heated slab is subjected to 4 passes of rough rolling, the starting rolling temperature is 1080°C, the final rolling temperature is 1005°C, the average reduction rate of a singl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com