Coke oven raw gas sensible heat and hot coke sensible heat combined power generation process and system

A technology of combined power generation and raw gas, applied in the field of coking, can solve the problems of coke oven raw gas without effective recovery means, technology complementarity, and enterprise safety production, etc., to improve waste heat recovery efficiency, wide application range, and implementation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

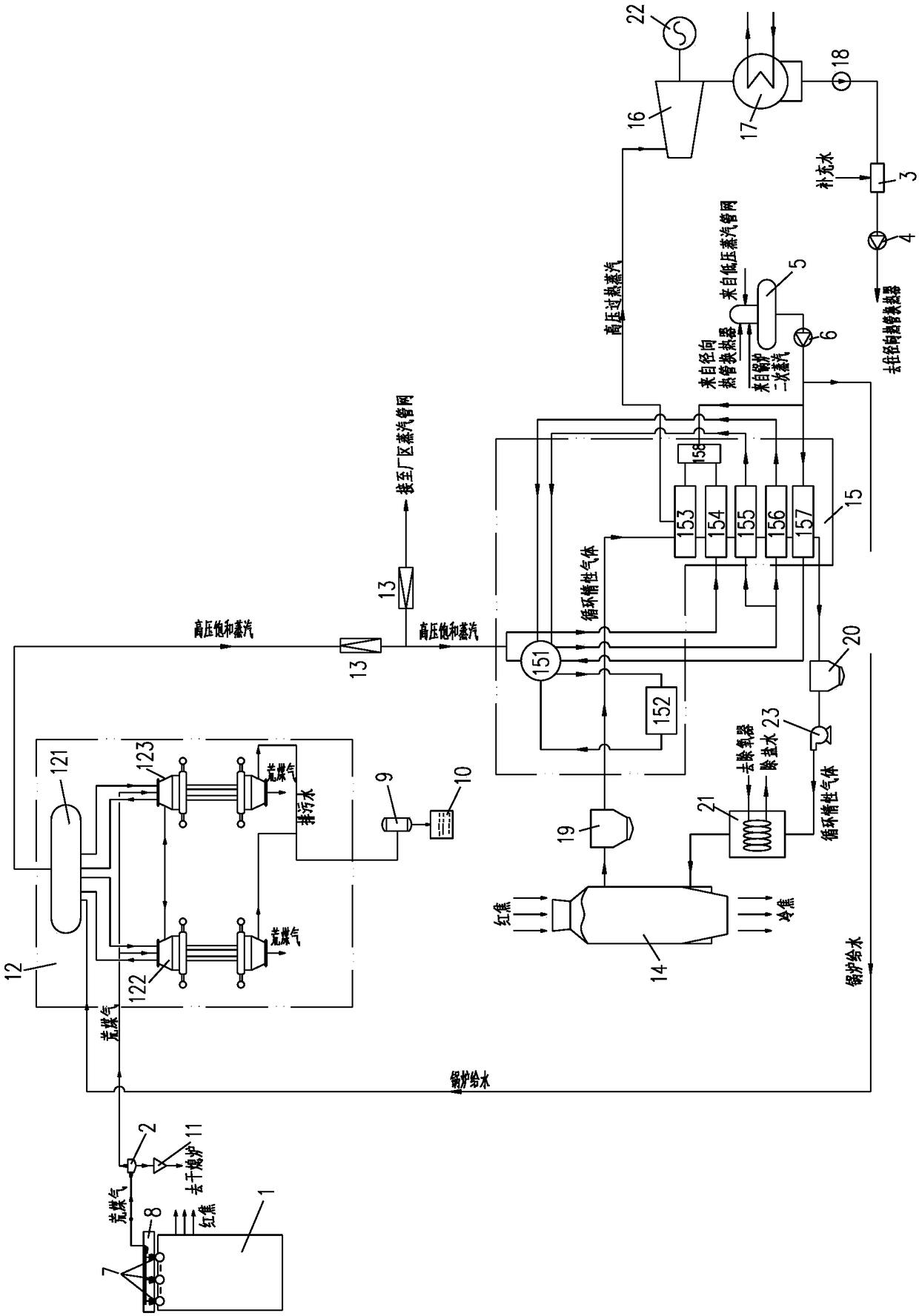

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0021] The combined power generation process of raw coke oven gas sensible heat and red coke sensible heat described in the present invention adopts a set of water supply device to supply water to CDQ boiler 15 and raw gas waste heat boiler 12 at the same time, all the way in raw gas waste heat boiler 12 and Raw coal gas produces saturated steam after heat exchange, and the other channel produces saturated steam after heat exchange with red coke in CDQ boiler 15, and the two saturated steam channels enter CDQ boiler 15 for superheating after being superheated, and then enter steam turbine 16 for power generation .

[0022] A joint power generation process of coke oven raw gas sensible heat and red coke sensible heat, specifically comprising the following steps:

[0023] (1) The raw coal gas exported from the gas collection pipe 8 of the coke oven...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap