Intake valve type eddy current scavenging two-stroke diesel engine

An intake valve, two-stroke technology, applied in mechanical equipment, combustion engines, machines/engines, etc., can solve the problem of incomplete exhaust gas discharge, and achieve the effect of simple structure, low cost, and enhanced workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

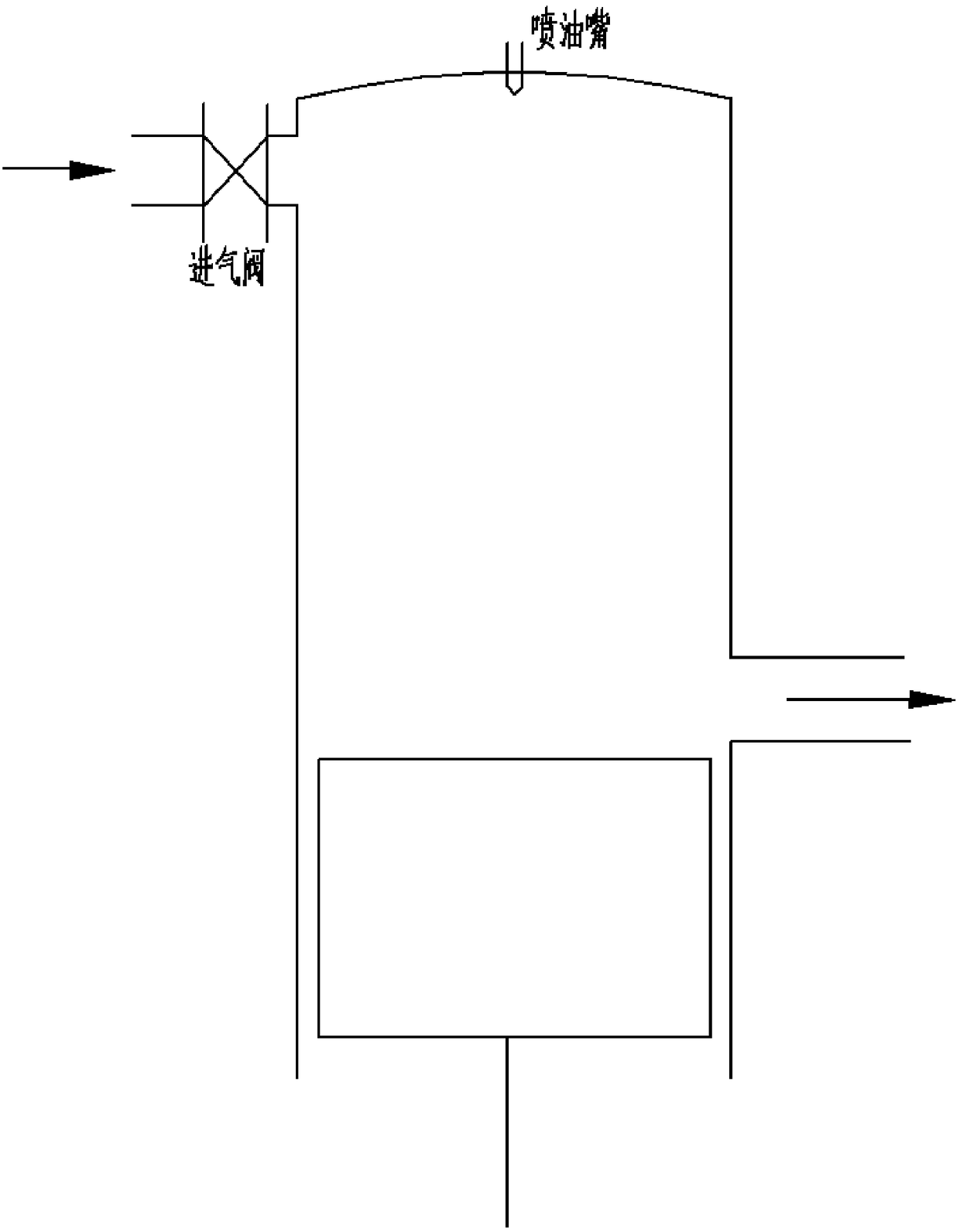

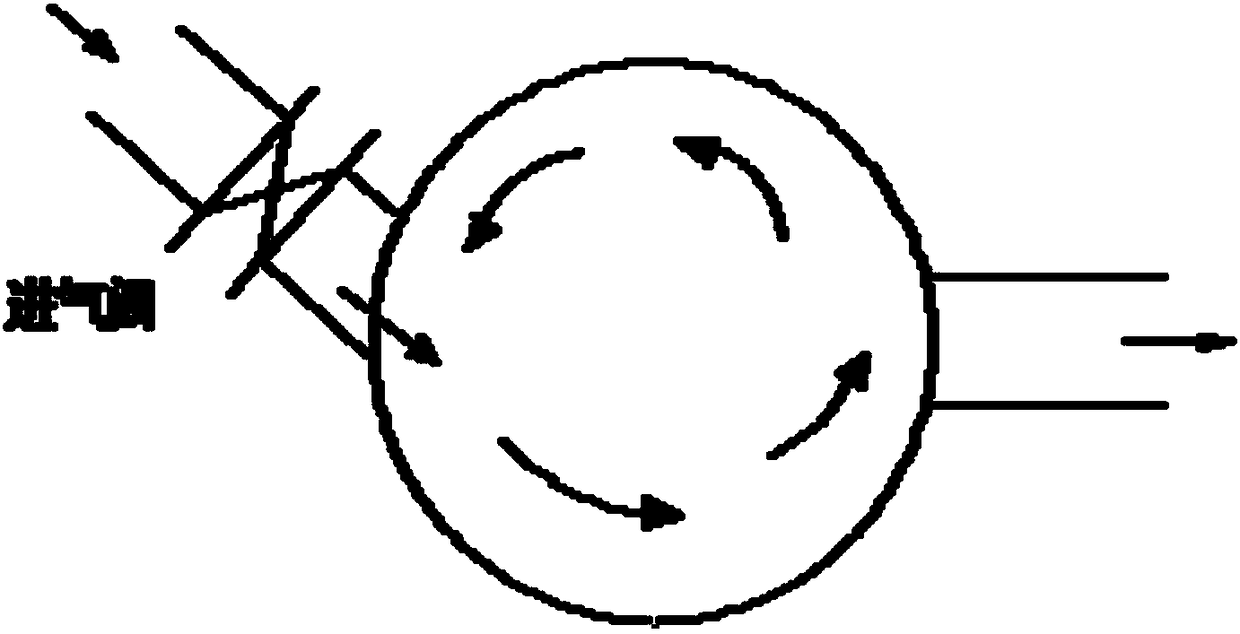

[0022] combine Figure 1-2 , The specific structure of the cylinder of the present invention includes: a turbocharger system, a cylinder, a piston, an oil injector, an exhaust port and an air intake with an intake valve. The intake port is located near the top of the cylinder side, and an intake valve is installed; the exhaust port is located at the lower part of the cylinder side, and is respectively located on both sides of the cylinder with the intake port. Due to the presence of the intake valve, the exhaust port can be opened prior to the intake port for exhaust. After the exhaust is performed for a period of time, the intake valve opens and the intake begins. In addition, the axis of the intake port is not parallel to the normal line of the cylinder, but forms an angle of about 60° with the normal line of the cylinder. Therefore, the fresh air will flow in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com