Push-pull combination insulation device and high-temperature vacuum sintering furnace

A heat preservation device, push-pull technology, applied in furnaces, muffle furnaces, cooking furnaces, etc., can solve the problems of time-consuming, laborious, damage, inconvenient operation, etc., and achieve the effect of avoiding damage and accelerating the cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

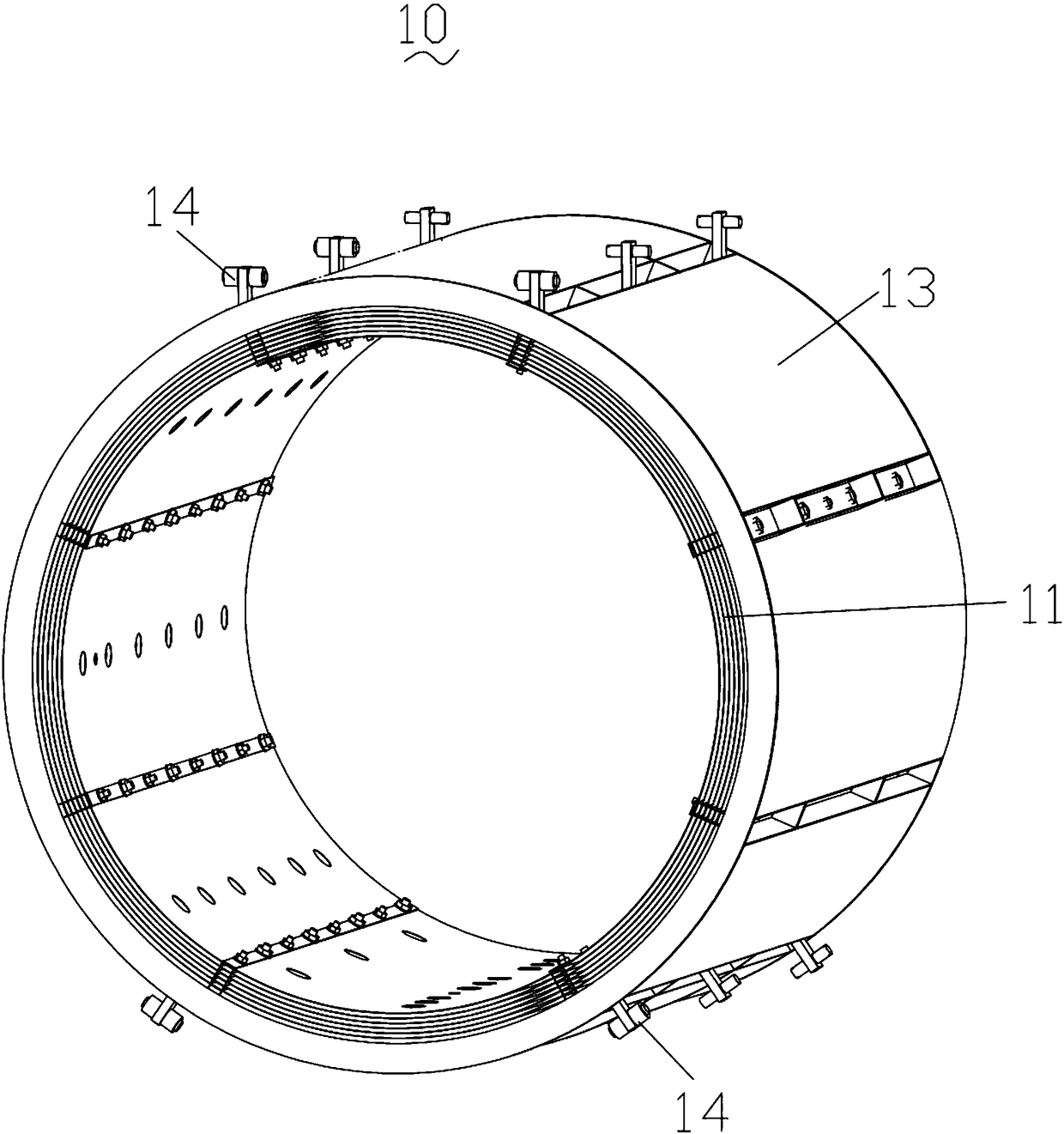

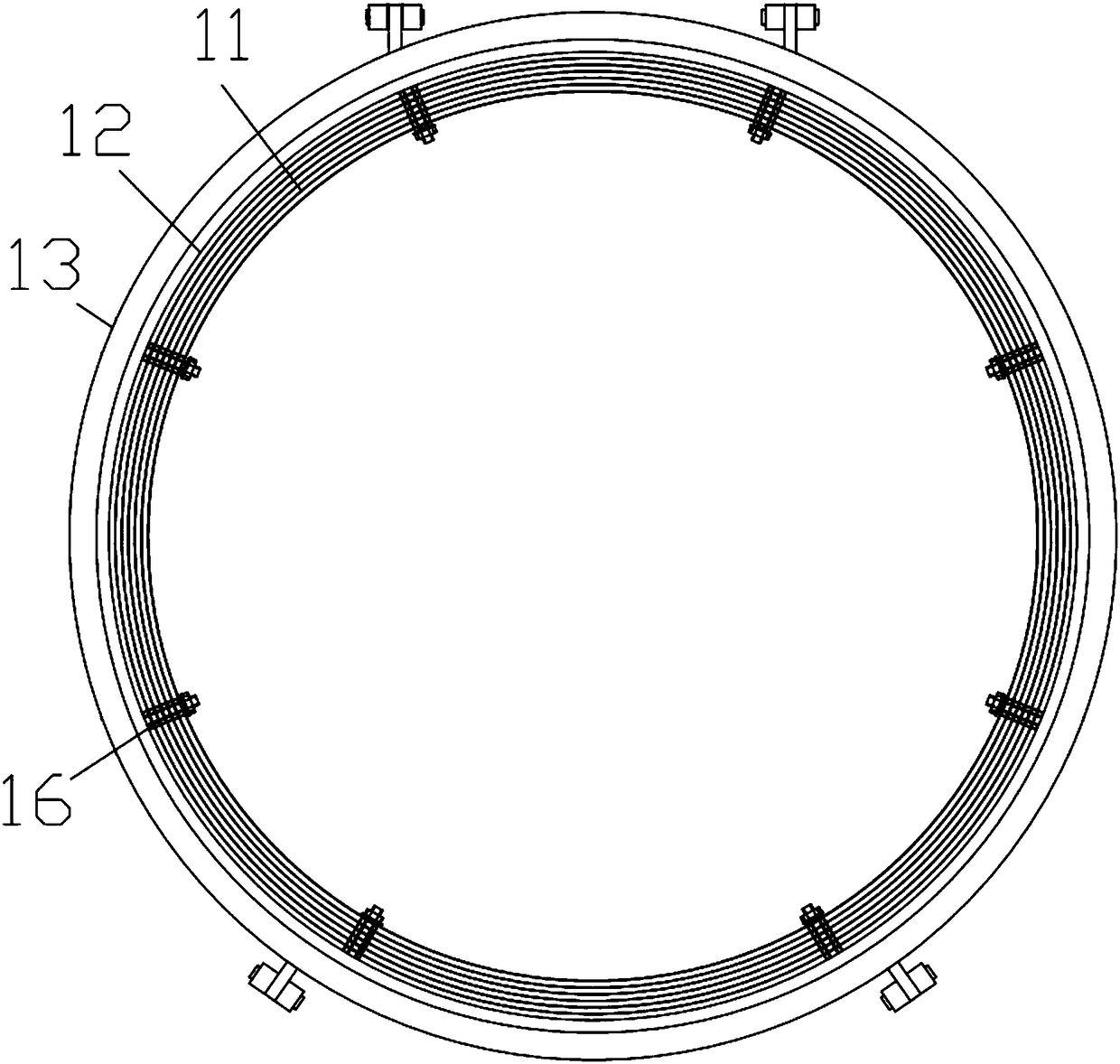

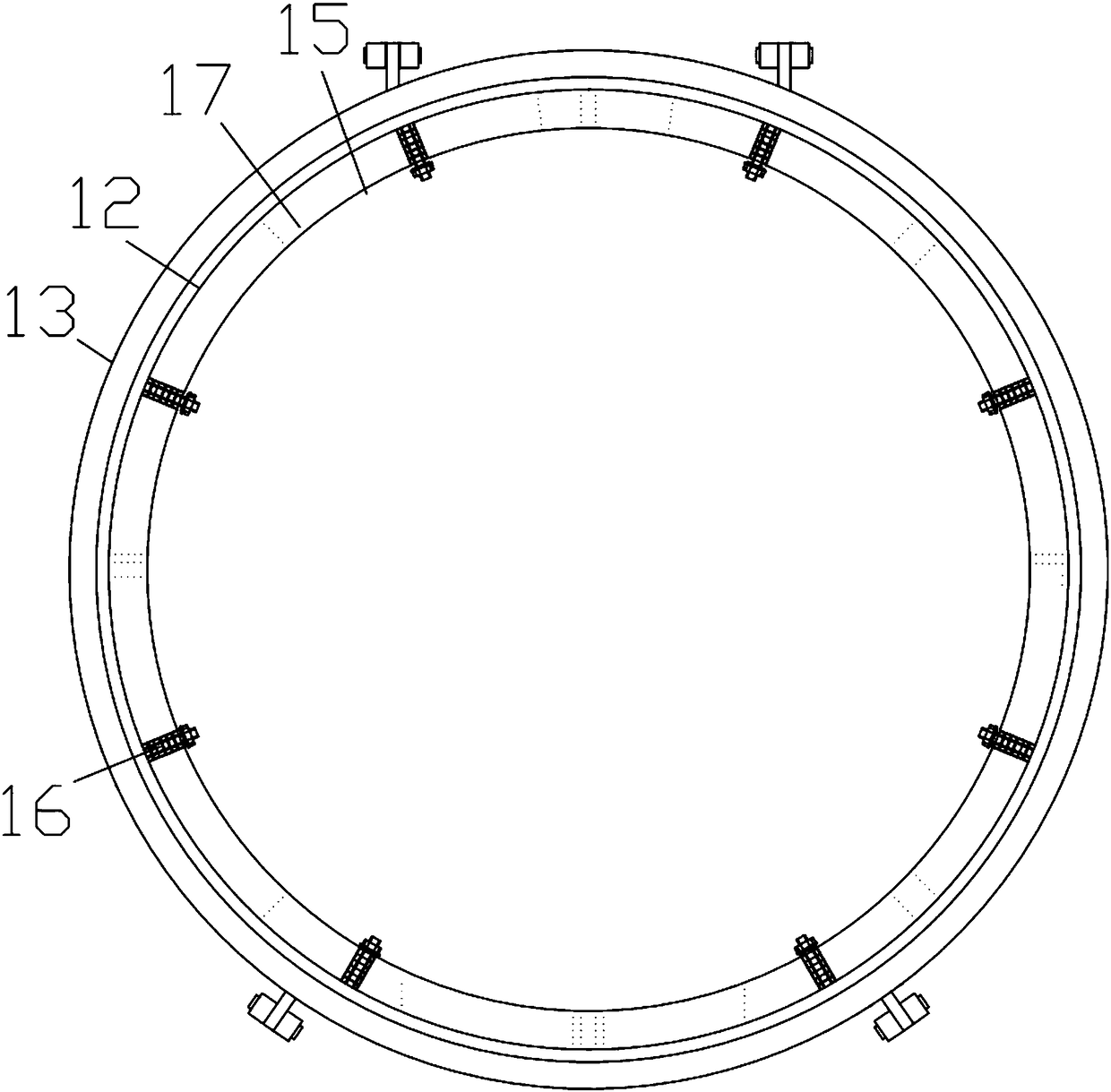

[0021] see Figure 1 to Figure 3 , the embodiment of the present invention provides a push-pull combined thermal insulation device 10, including thermal insulation layer 11, outer cooling layer 12, reinforcement layer 13, push-pull member 14 arranged sequentially from the inside to the outside, the thermal insulation layer 11 is formed by stacking several layers of heat shields The outer cooling layer 12 is a jacket layer wrapped on the outer wall of the insulation layer 11, and the inside of the jacket layer is filled with a cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com