Liquid-filled double-core photonic crystal fiber

A photonic crystal fiber and liquid technology, which is applied in the directions of multi-core fiber, cladding fiber, optical waveguide light guide, etc., can solve the problems of difficult to meet the wide and large-capacity optical communication network, long physical length and low splitting ratio, etc. The effect of high extinction ratio characteristics, short physical length and high splitting ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

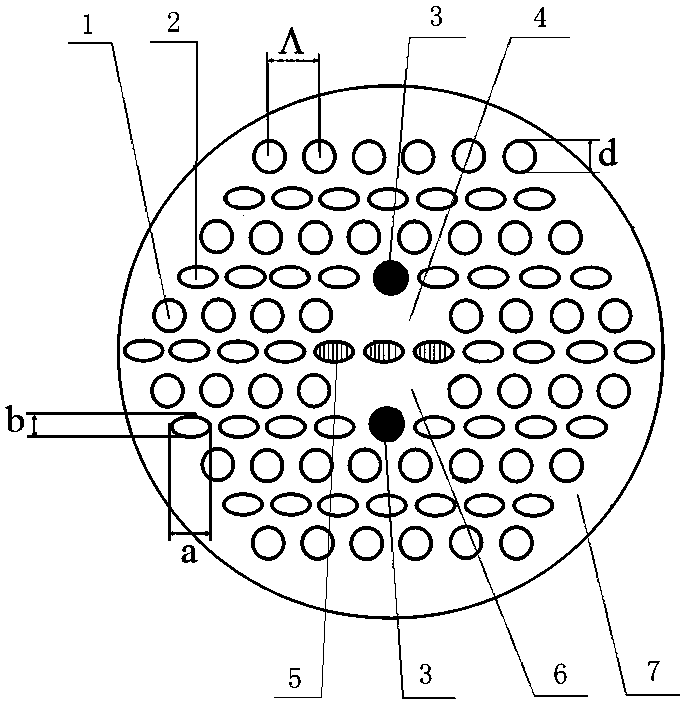

[0017] Such as figure 1 As shown, a dual-core photonic crystal fiber filled with liquid 5 of the present invention includes two cores and cladding layers 7 arranged around the two cores. The cross-section of the cladding 7 is circular, and the two cores are distributed near the center of the cladding 7 and located respectively at figure 1 The position of the upper and lower sides of the horizontal central axis of the cross section of the middle cladding layer 7 . A plurality of air holes are arranged at intervals along the length direction of the cladding 7 in the cladding 7 , and the projections of the multiple air holes on the cross section of the cladding 7 are distributed in rows. Such as figure 1 As shown, the present embodiment includes eleven rows of odd-numbered air holes, wherein the odd-numbered rows of air holes include a plurality of first air holes 1 whose cross-sectional shape is circular, and the even-numbered rows of air holes include a cross-sectional shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com