interlayer coupler

A coupler and cladding technology, applied in the field of three-dimensional photonics integration, can solve the problems of increasing the overall size of the chip, long coupling length, low error tolerance, etc., and achieve the effects of cost saving, high coupling efficiency, and reduced size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

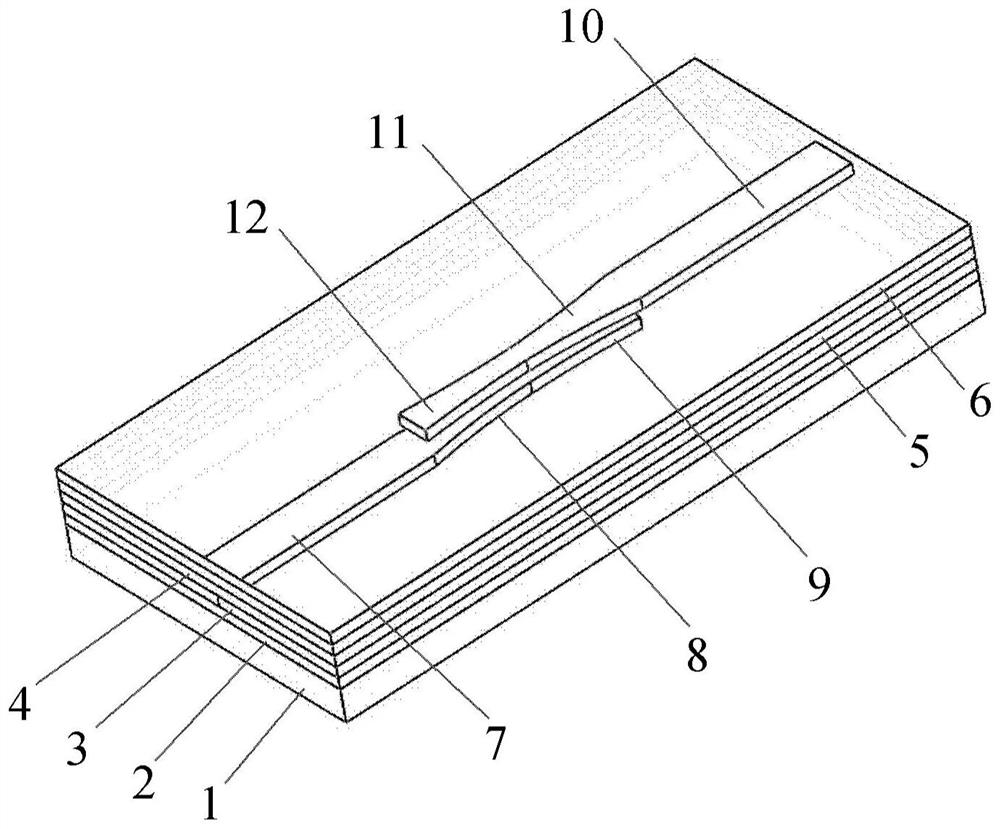

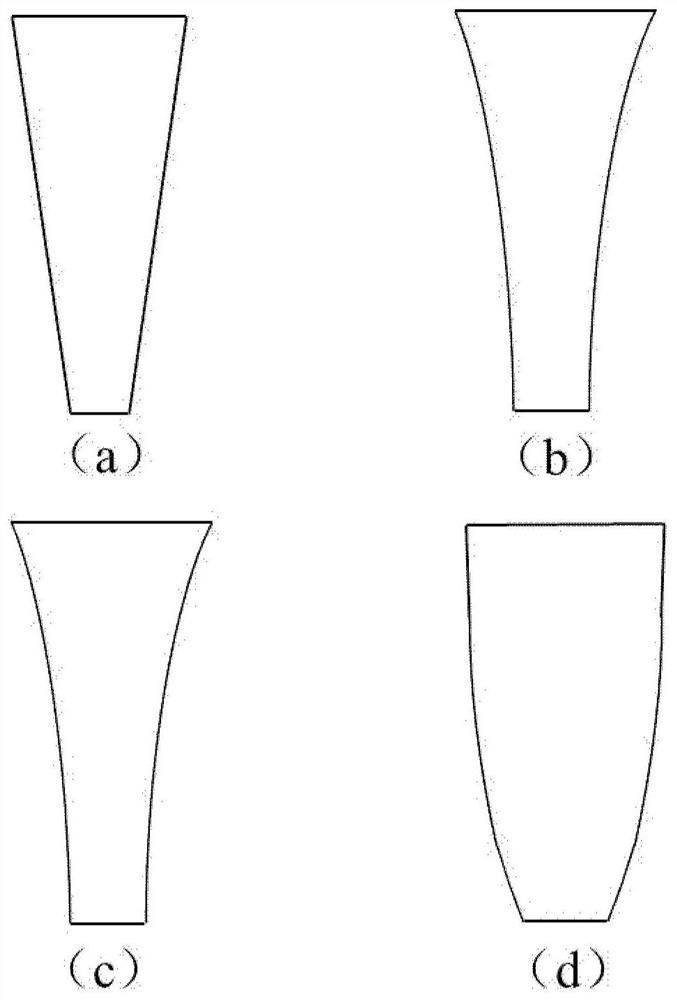

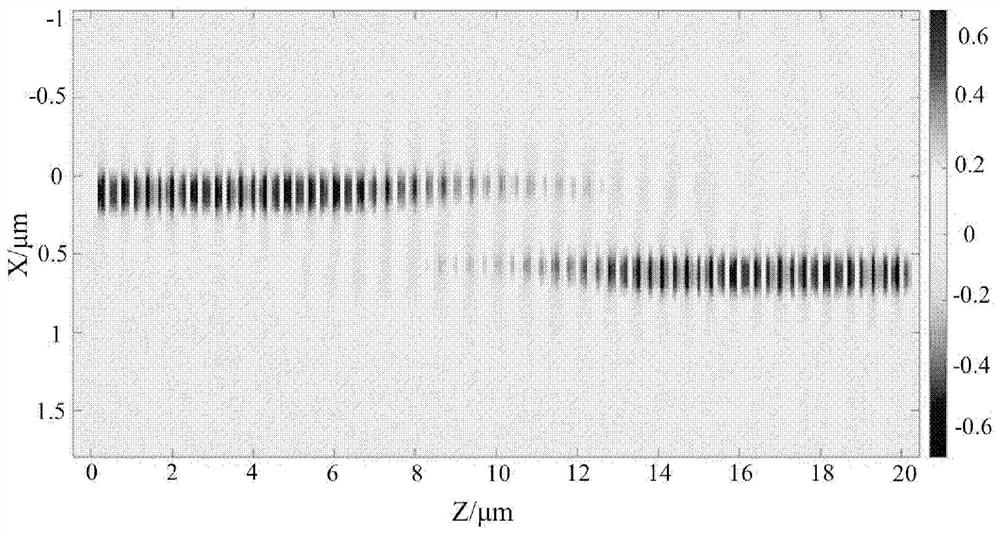

[0081] In this embodiment, using as figure 1 The interlayer coupler structure shown. Wherein, the material of the substrate 1 is silicon, and the thickness is 100 μm. The material of the lower cladding layer 2 and the upper cladding layer 6 is silicon dioxide with a thickness of 2 μm. The material of the middle cladding layer 4 is silicon dioxide with a thickness of 300nm. The material of the first waveguide layer 3 and the second waveguide layer 5 is silicon, and adopts a ridge waveguide structure. The width of each waveguide is 0.5 μm, the thickness is 220 nm, and the thickness of the plate is 70 nm. In the first waveguide layer 3, the widths of each section of waveguide are respectively: the width of the first waveguide 7 is 0.5 μm; in the first tapered waveguide 8, w 1 = 0.2 μm, w 2 =0.5μm, f(z)=z^2; in the second tapered waveguide 9, w 1 = 0.2 μm, w 2 =0.36 μm, f(z)=z^3. In the second waveguide layer 5, the widths of each section of waveguide are respectively: the ...

Embodiment 2

[0087] The difference between this embodiment and Embodiment 1 is that in this embodiment, the first waveguide layer 3 and the second waveguide layer 5 adopt a rectangular waveguide structure, the width of the waveguide is 0.4 μm, and the thickness is 220 nm. In the first waveguide layer 3, the widths of each section of waveguide are respectively: the width of the first waveguide 7 is 0.4 μm; in the first tapered waveguide 8, w i = 0.24 μm, w 2 =0.4μm, f(z)=z^2; in the second tapered waveguide 9, w i = 0.24 μm, w 2 =0.32 μm, f(z)=z^3. In the second waveguide layer 5, the widths of each section of waveguide are respectively: the width of the second waveguide 10 is 0.4 μm; in the third tapered waveguide 11, w 1 = 0.24 μm, w 2 =0.4μm, f(z)=z^2; in the fourth tapered waveguide 12, w i = 0.24 μm, w 2 =0.32 μm, f(z)=z^3. In this embodiment, the above-mentioned four sections of tapered waveguides all have a length of 5 μm, and the formed interlayer coupling region has a length...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com