Radiator for electronic component

A technology for electronic components and radiators, applied in the field of electronic component radiators, can solve the problems of complex structure, short circuit, difficult to meet the needs of heat dissipation, etc., and achieve the effects of reducing heat source temperature, simple and compact structure, and improving heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

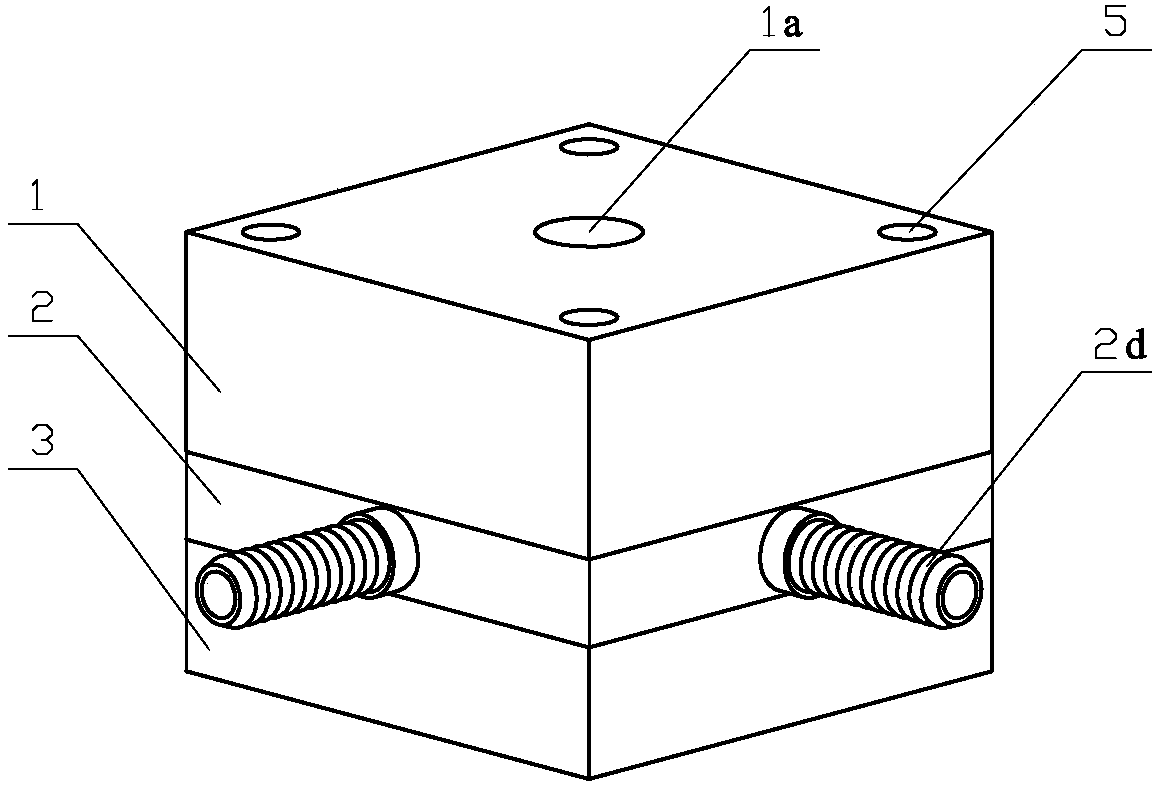

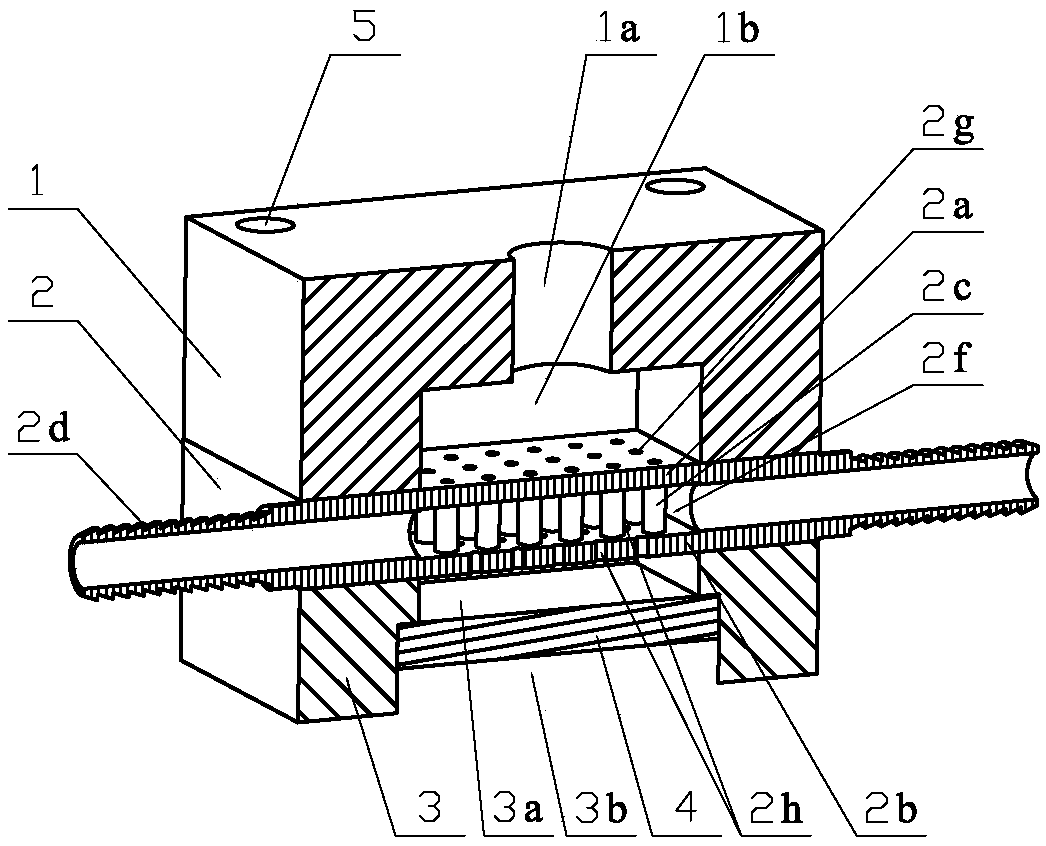

[0018] Figure 1 ~ Figure 4 Shown is the embodiment of a kind of radiator of electronic component of the present invention, as figure 1 As shown, it includes an upper air chamber part 1, a micro-jet hole part 2, and a lower mounting part 3 arranged sequentially from top to bottom to form a square column structure.

[0019] like figure 2 As shown, the middle part of the upper air chamber part 1 is provided with a fluid inlet 1a and an upper air chamber cavity 1b communicating with it.

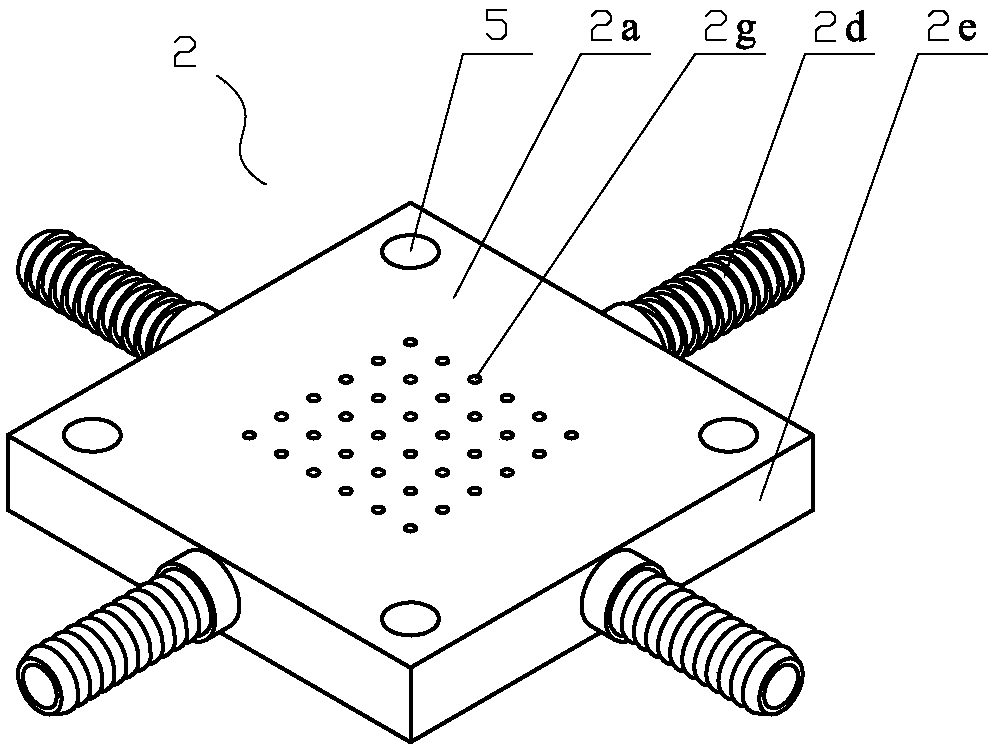

[0020] The micro-fluidic orifice 2 includes an upper micro-fluidic orifice plate 2a, a lower micro-fluidic orifice plate 2b, an airflow tube 2c, and a fluid outlet tube 2d. Wherein, the upper micro-fluidic orifice 2a is located in the upper air chamber cavity 1b, and is spaced apart from the lower micro-fluidic orifice 2b, and forms an orifice cavity 2f combined with the side 2e of the micro-fluidic orifice. The airflow pipe 2c is cylindrical, and is arranged side by side in the orifice cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com