Automatic processing apparatus used for track cable

An automatic processing and track technology, which is used in cable installation, cable installation devices, and equipment for dismantling/armoring cables, etc., can solve the problems of easy damage to the cable core, impact on cutting efficiency, low efficiency, etc., to extend service life, The effect of improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

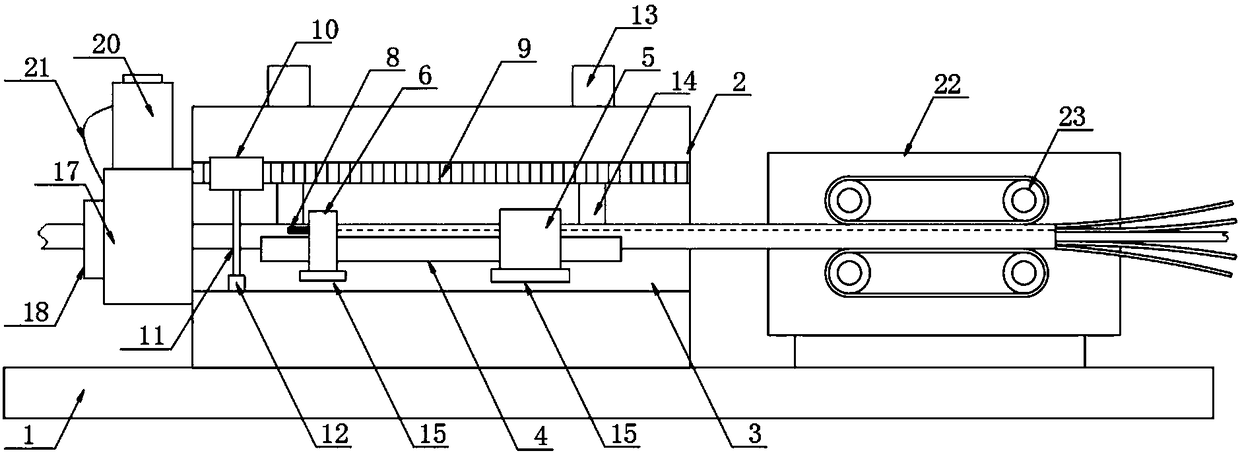

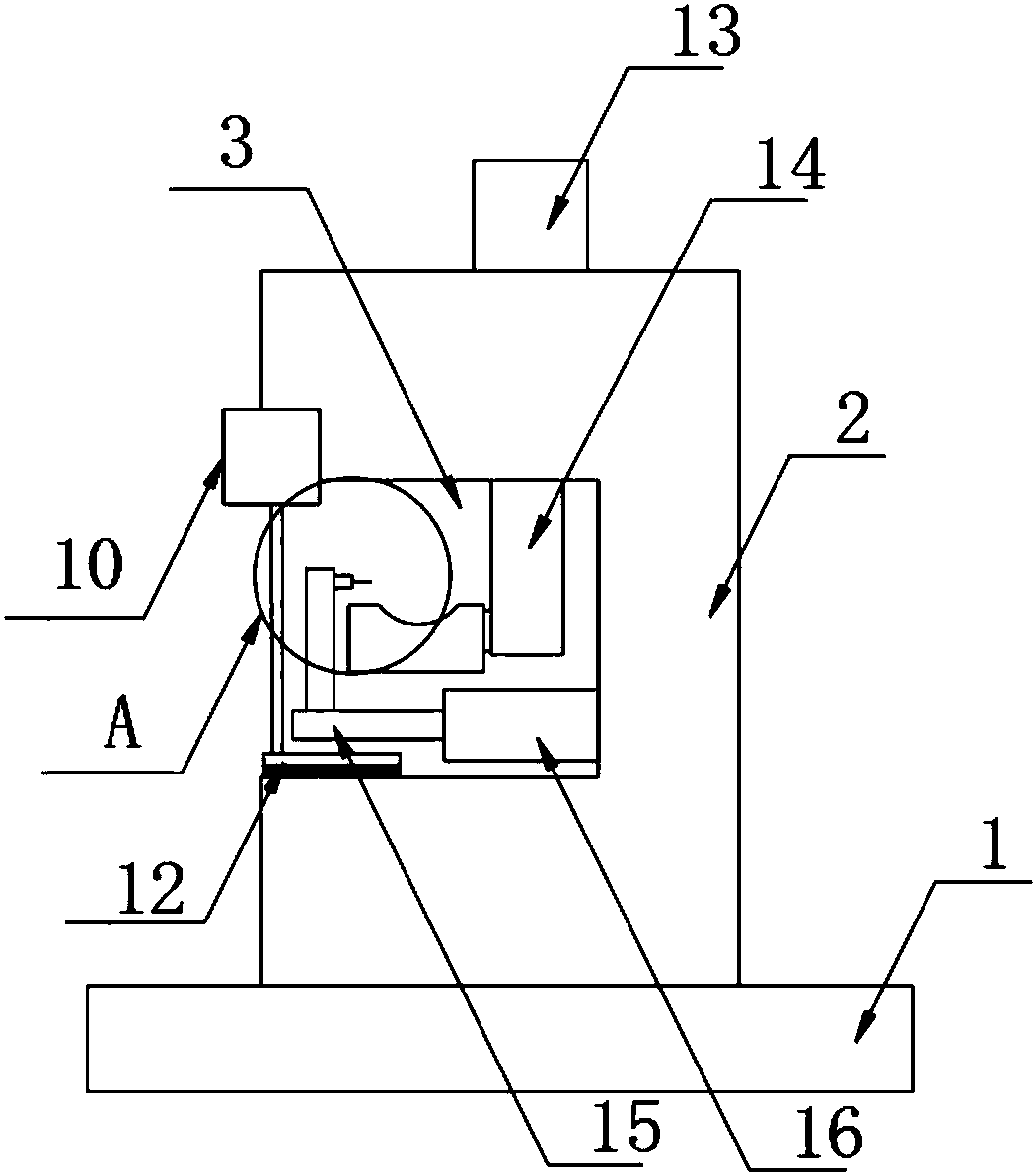

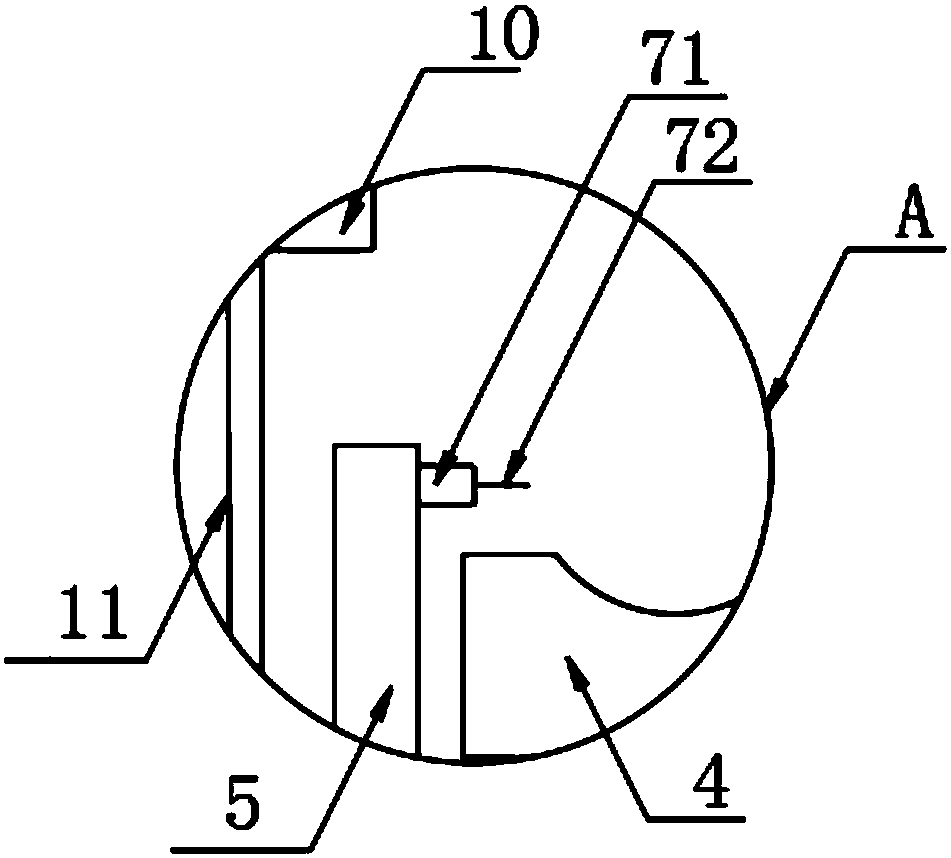

[0027] according to Figure 1-6 The shown automatic processing device for track cables includes a base 1 and a processing table 2, the processing table 2 is fixed on the top of the base 1, and a processing groove 3 is provided on one side surface of the processing table 2. Both ends of the processing tank 3 run through one end wall of the processing table 2 and extend to one side of the outer wall of the processing table 2. A conveying plate 4 is arranged inside the processing tank 3, and insulating parts are respectively installed at both ends of one side of the conveying plate 4. The connection plate 5 and the metal sheath connection plate 6, the insulation cutting device 7 is provided on one side of the connection plate 5, and the metal sheath cutting device 8 is provided on the one side of the metal sheath connection plate 6, the The insulating layer cutting device 7 and the metal sheath cutting device 8 are all arranged directly above the conveying plate 4, and the insula...

Embodiment 2

[0030] The difference with embodiment 1 is:

[0031]The first cylinder 13 is fixedly arranged on both sides of the top of the base 1, the bottom end of the first cylinder 13 extends to the inner cavity of the processing table 2, and the output end of the first cylinder 13 is provided with a first piston rod 14. A piston rod 14 runs through the top wall of the processing tank 3, and extends into the processing tank 3 to be fixedly connected to the side wall of the conveying plate 4. The bottom of the insulator cutting connecting plate 5 and the metal sheath connecting plate 6 are fixedly provided with a second Piston rod 15, the second piston rod 15 is arranged on the bottom end of the conveying plate 4, the other end of the second piston rod 15 is provided with a second cylinder 16, the output end of the second cylinder 16 is connected to the input of the second piston rod 15 The other end of the second cylinder 16 is fixedly arranged at the bottom of the side wall of the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com